The long and successful history of concrete overlays

The first documented use of concrete to resurface pavements dates back to 1901.

That first concrete overlay was one of 15 placed between 1900 and 1915, a fact that might surprise some people, considering that the first concrete pavements were placed in 1892 and 1893.

Although overlay technology has been around for more than a century, the focus of the first half of the 20th century was on building new highways, including the Lincoln Highway, Route 66, the Interstate Highway System, and other roadways and airports that linked our rapidly growing nation.

As the U.S. road network finally took shape, however, a new challenge emerged for highway engineers to address pavements that were exceeding their original design lives. As a result, finding cost-effective solutions to keep the road network going has been a constant challenge since the 1970s.

Concrete overlay solutions came into sharp focus during that decade, with four overlays placed in Iowa by the Jackson Construction Company (now Cedar Valley Construction). This was followed by a project in Detroit, where several contractors built the largest fiber-reinforced concrete overlay project to date at that time. The project was a 3-in.-thick concrete overlay placed on four of eight lanes on a highway carrying 100,000 vehicles per day.

This was followed by the construction of a storied test site and a comprehensive experiment on fiber-reinforced concrete in Greene County, Iowa. The Iowa Highway Research Board, Iowa Concrete Paving Association, and ACPA planned the test site and, in partnership, facilitated the research. Built in 1973, the project site was comprised of 2-, 3-, and 4-in. sections built with and without fibers. In all, there were 41 test sections on the test site, which became a de-facto proving ground for research and technology development that drew national and international attention for many years.

These construction and research projects raised interest in concrete overlays and created demand for a technology that eventually came to be known as “whitetopping”—and for overlays under 6 in. thick, “ultra-thin whitetopping.” Thereafter, the use of concrete overlays increased steadily for a number of years—but soon, all that would change.

Advancing Concrete Overlay Technology

Following an ACPA-led initiative to coalesce concrete pavement research throughout the country, the National Concrete Pavement Technology Center (CP Tech Center) was founded in 2005 to serve as a hub for concrete pavement research and technology.

With initial financial support from the concrete, cement, and ready-mix sectors, along with cooperative research projects, the CP Tech Center worked to develop resources to meet the increasing interest in this technology.

An early publication, the “Guide To Concrete Overlays,” now in its 3rd edition, provided agencies, engineers, and contractors with useful information about how to apply concrete overlays to address almost any existing pavement condition. With input from ACPA and other stakeholders, the guide and other resources continue to provide practical information for determining candidate projects and gaining insights into materials, typical sections, and important construction details.

“The increased acceptance of concrete overlays was a direct result of ACPA and the affiliated chapter network, which worked closely with the CP Tech Center to develop resources and make information available to agency/owners, engineers, and contractors,” American Concrete Pavement Association (ACPA) President and CEO Gerald F. Voigt, P.E., said. “Federal Highway Administration’s support of these technology transfer efforts was also very important. The use of concrete overlays for pavement resurfacing has been responsible for an increasing share of the concrete pavement usage for well over a decade. Overall, concrete pavements helped ease the industry through the Great Recession of 2008, and of course, during the current challenges brought on by the global pandemic. We expect that overlays will again be key to a steady and stable market moving forward.”

Since about 2005, the use of the overlays has risen from about 3-4% of the volume of concrete pavement placed across the country annually to an average of more than 12%.

“Engineers are selecting concrete overlays for almost any type of existing need—from failed asphalt pavement to old concrete sections,” Voigt added. “Year over year, the most common application is now concrete over distressed asphalt, or what is sometimes called BCOA. We’re seeing an increasing number of projects where owners are specifying concrete, which is a great market enhancement, because for many years the perception was that there was only one option available for those pavements—another asphalt overlay.”

According to Voigt, the marketplace is seeing more designs that are 6 in. thick or less, and with this trend toward thinner sections has also come shorter joint spacing. More designs are calling for 6-ft x 6-ft squares for concrete overlays, and the shorter joint spacings are creating slabs that are more resistant to bending and are therefore stronger.

“We are not just seeing overlays on highways either,” Voigt said. “We are seeing a proliferation of concrete overlays in every market, including airports, high-capacity and low-volume streets, and industrial areas.”

Such demand is being driven, Voigt believes, by a greater awareness of the technology and the desire for more sustainable and resilient pavement solutions: “The traveling public is increasingly intolerant of frequent repair and replacement cycles because it’s not just the cost of the repairs—it’s also an awareness that those processes require tax dollars, fossil fuels, and often excessive traffic delays and disruptions.”

The application of concrete overlays has reduced the frequency of required replacement or repair to a roadway. As a result, traffic impacts, including shutdowns and lane closures, have been significantly reduced, as has the danger of exposing workers and motorists to construction work zones.

Milestones and Critical Needs

Despite the ongoing struggles associated with the COVID-19 pandemic and its impacts on our industry, 2020 has been a pivotal year for the continued advancement of concrete overlays. “We are very pleased that the FHWA in late August announced that overlays have been selected by the agency’s Every Day Counts (EDC) program for rapid deployment,” Voigt said. “The inclusion of concrete overlays in EDC’s pavement solutions (TOPS) as one of the innovations [for 2020/2021] means added visibility for the technology and recognition for the agencies that are using overlays to address challenges and opportunities creatively.”

FHWA describes its intent to shine a light on “solutions for integrating innovative overlay procedures into practices that can improve performance, lessen traffic impacts, and reduce the cost of pavement ownership.” Pavement overlays were one of seven innovations recognized in the current round. Approximately half of all infrastructure dollars are invested in pavements, and more than half of that investment is in overlays. By enhancing overlay performance, state and local highway agencies can maximize this investment and help ensure safer, longer-lasting roadways for the traveling public.

The EDC program points to the many benefits of concrete overlays, including safety gains, cost savings, and performance. The agency has also included brief information about the state of the practice, stating that “recent improvements to design methods, interlayer technology, slab geometry, and concrete mixtures have broadened concrete overlay surface treatment applicability, reliability, sustainability, and cost-effectiveness.”

Contributing to the acceptance and increased use of concrete overlays have been a number of tools and resources—among which are:

The aforementioned overlays guide and dozens of other printed resources, webinars, and other material from the CP Tech Center.

PavementDesigner.org, the concrete and cement industries’ concrete pavement thickness design portal. Available free of charge, the program offers different design solutions for parking areas, streets, and intermodal facilities. No user ID or password are needed, but registered users can save designs to a cloud account.

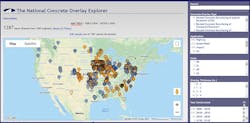

ACPA’s National Concrete Overlay Explorer, a web-based resource that provides details about more than 1,200 projects. The explorer is searchable by overlay type, application by market, pavement thickness, and of course, locations in 46 states, as well as in Alberta, Canada. The explorer also includes project size, joint spacing, and reinforcement, along with a few finished project and construction photos.

ACPA’s Applications Library, which hosts dozens of digital device apps.

Keeping up the momentum

There is still work that needs to be done, and work is continuing on many different fronts. Voigt notes that forward movement will continue to come through sharing and outreach forums, such as the latest Concrete Overlay Summit (held in virtual format in October). The summits have become an annual event, bringing together those with interest in further advancing concrete overlay technology.

Moreover, research and technology efforts also continue in the areas of fiber reinforcements, fabric interlayer technology, cement and other materials technology, and equipment and testing instrument advances. One of the important steps in this direction is performance-engineered mixtures (PEM). The PEM initiative, led by FHWA with support from key industry and agency stakeholders, holds great promise for helping concrete pavements perform better under any application, including overlays.

In general, PEM is aimed at implementing what is known, refining performance monitoring and specification refinement, and measuring and relating early-age concrete properties to performance. The initiative has already had some early success, including advancing testing to reach beyond traditional slump, strength, and air measurement and focusing instead on new approaches to strength and concrete workability.

“The goal of PEM,” Voigt said, “is to enable contractors to achieve consistent quality in concrete mixtures, and in turn, to deliver reliable concrete pavements every time, all the time.”

It is a lofty goal, but one that many industry professionals see as an important step in advancing to another 100 years of quality concrete overlay projects. Achieving that goal could mean that a growing number of overlays could still be in service in the next century.