What a blast

Blastrac introduced the 2045DT Mounted Blaster for the first time in North America at the 2008 World of Concrete in Las Vegas Jan. 21-25. This new blaster was introduced by the Blastrac Highway and Airport Division to meet the increased demand for higher-production surface-preparation equipment. The 2045DT builds on the success of the 204800HMKIII shot blaster for larger projects.

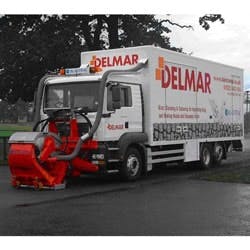

With a 45-in. blast pattern, this totally self-contained unit offers versatility that is currently unavailable in North America. The highway-ready truck has all the required equipment contained inside the customer truck body. Once on-site, the closed-circuit, dust-free shot blasting process is attached to the front and controlled by a single operator from the cab of the specially modified truck.

Dust collection, abrasive storage, hydraulic controls and spare parts are all carried conveniently inside the truck body, eliminating the need for additional support equipment. Large projects require specialized tools for fast, efficient and environmentally acceptable tools, and the 2045DT successfully retextures asphalt, concrete roads, highways and airport runways and taxiways, as well as removes rubber. It also can be used for surface preparation of bridge decks prior to the application of waterproofing membranes or polymer concrete toppings.