First-of-its-kind bridge opens in Tampa Bay with community stakeholders prioritized

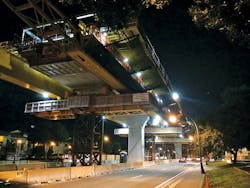

The newly completed Selmon Extension is an elevated 1.9-mile two-lane, tolled roadway located in Tampa, Florida, built by the Tampa Hillsborough Expressway Authority (THEA).

The toll road connects to the Lee Roy Selmon Expressway—a connector route for Tampa commuters that is owned, managed, and operated by THEA. Before the Extension, the expressway linked South Tampa neighborhoods to the urban center of downtown Tampa and the city’s eastern suburb of Brandon, but commuters traveling into town from neighboring Pinellas County were stuck in a congested route along Gandy Boulevard (S.R. 600 / U.S. 92) that consisted of busy intersections and long stoplights before being able to connect to the expressway.

“Seeking to reduce commuter traffic throughout the South Tampa neighborhoods and address expanding population growth, THEA responded with a solution that would work with the local community’s needs and provide regional connectivity—the Selmon Extension project,” said Joseph Waggoner, THEA Executive Director.

“The Extension provides a critical, regional link for businesses, freight, and people,” Waggoner went on to say.

On three separate occasions over the last 25 years, the Florida Department of Transportation (FDOT) tried to find a solution to reduce congestion on Gandy Boulevard. The suggested alternatives would have required acquisition of vast amounts of homes and/or businesses along the corridor and therefore were met with fierce community opposition.

“This project has been 25 years in the making and required giving the community a different type of solution—an elevated toll lane located in the median of Gandy Boulevard that did not disturb businesses or homes,” said Waggoner.

THEA took a grassroots approach with ongoing community outreach and Chamber of Commerce partnerships to ensure that the agency was listening and responding to the needs of community stakeholders. Innovative design-build solutions laid the groundwork for a bridge that now gives “pass-through” traffic a smooth, direct route between the two counties and increases capacity on Gandy Boulevard for neighborhood traffic and customers of Gandy Boulevard businesses by over 35%.

CONNECTING COMMUNITY

THEA began construction of the $230 million project in December 2017 and completed it in April 2021. All along, community outreach was an essential part of the project. THEA had a ground support team that connected with local businesses along Gandy Boulevard to listen and provide project updates.

“We knew the region needed to be more connected with an option for travel between the two counties that would benefit commuters from both sides of the Bay,” said Susan Chrzan, THEA Director of Public Affairs and Communications. “To make sure our approach was in line with community needs, we surveyed all the Gandy businesses and discovered concerns we could address.”

Business owners were worried that construction would close lanes and driveways, which would negatively impact their business. THEA spent years listening to business and community concerns and created a multi-pronged game plan.

“Our agency took an always available, always listening approach,” said Chrzan. “We engaged community leaders and grassroots leaders in full discussions about the project, working diligently with the region’s Chamber of Commerce Board of Directors and Executive Directors, as well as neighborhood associations. We also created a traffic plan that minimized lane closures during construction and built an innovative bridge design based on not just traffic needs, but also neighborhood needs.”

THEA created a marketing campaign called “Shop Gandy!” The marketing campaign’s objectives aimed to drive commerce to all the companies in the shopping district before, during, and after the construction of the Selmon Extension. Four regional Chambers of Commerce, although initially concerned about impacts to member businesses along Gandy Boulevard, voted to officially support the Selmon Extension. The Construction Engineering & Inspection (CEI) and Public Involvement Team personally visited every business along the corridor to update them on the project’s progress and to hear any concerns.

DRIVING INNOVATION

For the Selmon West Extension, THEA unveiled an innovative design that has never been used before in the U.S. The bridge’s distinctive “finbacks” are aesthetically pleasing and provide support for the bridge deck, enabling longer span lengths between pier columns and reducing the height cross-section for the precast segments.

“THEA challenged our design-build team to come up with an innovative and aesthetically pleasing design that would minimize the negative effects of construction on the businesses along the Gandy corridor,” said Waggoner.

The Kiewit team proposed an elegant extradosed concrete segmental viaduct for most of the length along Gandy Boulevard, transitioning to steel tub girders similarly shaped and painted to match the segmental portion of the interchange on the east end of the project. The bridge foundation consists of 55 piers and caps supported by four redundant drilled shafts for each pier. The extradosed tendons—similar to a cable-stayed bridge with the cables encased in concrete finbacks—allow a shallow superstructure and longer spans between piers, which is particularly critical at the Westshore and Manhattan intersections.

A total of 744 segments were precast off-site and transported to the project site for erection and post-tensioned into the viaduct structure. Every segment cast has another segment that is cast right up against it, so they lock together.

“The elevated bridge is three different bridge types combined,” said Matthew Kappler, Project Administrator at Cardno, which served as consultant to the Kiewit team. “These include precast concrete segments, steel tub girders, and prestressed concrete beams.”

The concrete segments were trucked in from the casting yard and loaded onto the gantry and truss starting at the west end of the bridge. The segments were installed, epoxied together, and post-tensioned. As spans were completed, temporary towers were advanced. Segment installation, tensioning, and gantry/truss advancement activities were performed at night when the inside lanes next to the median could be closed. However, during the daytime, two lanes of traffic remained open, as were driveways to most businesses along the jobsite.

There are seven ramps at the interchange on the east end of the project and nine mechanically stabilized earth (MSE) retaining walls to support those ramps. Over 1,400 ground improvement piles were installed within the interchange area to provide additional support to the ramps and MSE walls to mitigate the poor existing soil conditions.

Simultaneously, work within the interchange area took place as well. The interchange construction was not as constrained as the work in the median of Gandy Boulevard, because much of the work did not impact traffic and was performed during the day. Utility work was significant throughout the corridor, with the relocation of electrical transmission and distribution lines, numerous multiagency intelligent technology systems (ITS), telecommunication and fiber optic lines, and water and wastewater mains.

Additionally, this was the first post-tensioned segmental bridge project in Florida to use a flexible wax filler material to protect the tendons rather than cementitious grout. This will significantly improve THEA’s ability to inspect, maintain, and repair any future issues that might develop with the post-tensioning tendons.

In total, the project includes three toll gantries, all located within THEA’s right-of-way at the interchange on the east end of the project. One gantry is for travelers accessing the Extension from the Selmon Expressway. Another is for those entering the South Dale Mabry Highway ramp, and the third serves drivers commuting from Pinellas County and getting off at the Dale Mabry interchange. Tolling is completely electronic with toll-by-plate and the SunPass prepaid toll program.

KEEPING PROMISES & MEETING CHALLENGES

“As beautiful and elegant as the finished bridge is, the engineering and construction of it are what enabled THEA to keep its promises,” said Waggoner.

The final bridge is a near-twin of THEA’s rendering. The innovative design of the Selmon Extension, with 30 ft of vertical clearance—twice as high as a typical urban bridge—allowed easy access and visibility for businesses along the Gandy corridor. The sleek design takes the Extension bridge out of a driver’s line of sight, allowing the driver to see businesses and turn lanes from both sides of Gandy Boulevard.

Based on the business surveys, THEA knew the pile-driving work would disturb and disrupt business.

‘To accommodate the needs of the community, the drilled shaft foundations were installed from west to east in the Gandy median,” said Waggoner. “We went from one side to the other and only did the drilling at night.”

Workers and equipment were protected from traffic by low-profile barriers and were able to maintain two lanes of traffic in each direction during the daytime and the rush hours. Temporary piers with auger-cast foundations were installed between the permanent pier locations, and the temporary piers were used to support the truss holding the gantry.

“While most urban bridges have 16.5 ft of clearance, business owners along Gandy Boulevard were concerned that such a bridge would block their business’s sightline,” said Waggoner. “We listened to their concerns and built the bridge taller (30-ft clearance) to give greater visibility to businesses for the local travelers below, and also reduced the number of piers supporting the structure—again for increased visibility for the businesses.”

The Selmon Extension utilized high-strength concrete and steel reinforcement to reduce the size and weight of the segmental bridge structure. The use of this material, along with the unique finback extradosed tendon design, allowed THEA to construct the superstructure with longer spans and taller piers in a small footprint within the narrow existing median of a four-lane divided urban arterial.

COORDINATION & CONGESTION RELIEF

Design and construction required continuous coordination with the Florida Department of Transportation, the city of Tampa, numerous local utilities, businesses, and adjacent redevelopment projects. The viaduct had to be constructed within a constrained urban corridor to minimize lane closures along the boulevard. After THEA performed a detailed safety analysis considering span length, sight distance, roadway clear zone criteria, and a commitment to maintaining access to existing cross streets and driveways, fixed pier locations were determined. Coordination was also required with the CSX railroad on the east end of the project at the rail crossing.

The elevated toll road was built in the median of Gandy Boulevard. The heavily trafficked boulevard, located in South Tampa, is an urban four-lane divided FDOT roadway connecting the Gandy Bridge over Tampa Bay to the eastern end of the Lee Roy Selmon Expressway, which THEA owns.

“We have significantly reduced traffic for our commuters and given the local community less congestion on their neighborhood roads,” said Waggoner. “The project’s opening marks the second time in 15 years that THEA has built a first-of-its-kind facility. In 2006, we completed the Selmon Expressway’s Reversible Express Lanes (REL) with all-electronic tolling. Like this project, the REL project reduced commute times and helped strengthen the economic corridors around the Selmon Expressway.”

JOB CREATION AND EXPANSION

With the final stages of this project being completed during the pandemic, the Selmon Extension became a vital economic contributor, employing more than 300 people during this difficult time. The project also activated corridors of prosperity by encouraging businesses to relocate to or expand their presence in this area, with corporate high-rise offices and mixed-use residential and retail developments now dotting the extension’s skyline.

“Effectively moving people and goods is vital for a thriving economy,” said Kelly Flannery, President and CEO of the South Tampa Chamber of Commerce. “We appreciate THEA’s efforts to meet with neighbors and neighborhood associations to listen to their concerns. They have connected every corner of our community as they plan for the future transportation needs of our region, protecting our neighborhood roads while promoting greater regional and local mobility.”