By: Shad Sargand

When designing typical highway pavements, engineers at the Ohio Department of Transportation (ODOT) strive to construct pavement structures that carry projected traffic loading for 20 to 25 years with little to no major maintenance.

However, Ohio currently has several asphalt concrete (AC) pavements that have been in service for 30 years or longer without significant structural distress. For example, a 4-mile (6.4 km) section of I-275 in Clermont County received the Asphalt Pavement Alliance’s Perpetual Pavement Award at the International Conference on Perpetual Pavement in 2014. The existence of such pavements makes it clear that AC pavements can last well beyond the standard design life.

Pavement engineers have devised a design called perpetual pavement that aims to replicate that level of success by creating a pavement that is designed to last longer than a half century without major structural rehabilitation or reconstruction. The surface will require very occasional minor resurfacing in response to upper layer distress, which minimizes the maintenance. The benefits of perpetual pavement are many. Obviously the costs of reconstruction of the road can be reduced if such reconstruction is less frequent, with savings in material and labor. This optimum use of materials and resources makes perpetual pavements more sustainable in the long run. In addition, the costs to the local economy due to delays and reduced fuel economy in construction zones are minimized. Safety is also improved due to less frequent construction/maintenance and due to better quality road surface, which further reduces costs.

The key to designing a perpetual pavement is eliminating bottom-up fatigue cracking. The perpetual pavement design includes a top layer designed to resist rutting and tire wear, an intermediate layer that also resists rutting, and a rich bottom layer designed to resist fatigue cracking, known as the fatigue resistance layer (FRL). The thicknesses of the layers are increased so that the strain at the bottom of the FRL, where it contacts the dense graded aggregate base (DGAB) never exceeds a specified value of the longitudinal tensile strain in regular use.

Trying it out

The first perpetual pavement design in Ohio was constructed in 2002 on six miles of I-77 in downtown Canton. After a dozen years of service, there are at present no signs of significant distress on the pavement. In December 2005, another perpetual pavement, a 16-in. (40.6 cm) thick design on the westbound lanes of a new bypass of Wooster on U.S. Rte. 30, was opened to traffic. A full suite of sensors was installed on two test sections to measure pavement response under load and to monitor environmental conditions. The instrumentation measured strain in each layer of the AC, the temperature profile in the AC, deflection of the pavement surface and bottom, long-term moisture content in the base and subgrade, and pressure in the subgrade. The perpetual pavement concept was verified using controlled load vehicle tests, where a truck at maximum legal load was driven over the test sections and the pavement strain responses recorded. At all but the most extreme cases, the strains at the base of the FRL were well below the design value, indicating that the pavement met the perpetual pavement design criterion.

With the basic perpetual pavement concept evaluated and shown to function as designed, the next step was to refine the thickness of the design. An experiment was set up in Ohio University’s Accelerated Pavement Load Facility (APLF) for this purpose. Four sections were constructed with AC thickness ranging from 16 in. down to 13 in. on DGAB. Again, the pavement in each lane was fully instrumented to model the response of each lane to the applied load. Response measurements were made with dual tire loads of 6,000 lb, 9,000 lb, and 12,000 lb, respectively, at temperatures of 40°F, 70°F, and 104°F. The longitudinal strain readings remained under the FRL design criterion. The highest temperature of 104°F was held for several days and extended through the full pavement depth, which was not realistic for Ohio, where a temperature gradient would exist in field. Because this represented an extreme condition not seen in Ohio, it was concluded that the reduced thickness pavement designs should also qualify as perpetual pavements.

Field testing

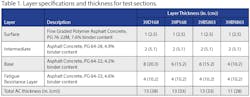

ODOT decided a field test of these designs was warranted, and four instrumented test sections using designs of respective thicknesses of 11 in., 13 in. (two sections), and 15 in. were installed on the Strategic Highway Research Program (SHRP) test road on U.S. Rte. 23 north of Delaware. Details of the pavement layers are provided in Table 1. These pavement layers were placed on 6 in. of DGAB that in turn rested on A-6 subgrade, which on the thinner sections 39BS803 and 39BN803 was stabilized with lime. Core samples were taken of the completed pavements to confirm their construction, and it was found that some portions of Section 39P168 were as thick as 16 in., and it was decided to exclude this section from the analysis; subsequent references to results from the 13-in. section refer to 39BS803. These sections were instrumented in a manner similar to the other sections in previous studies, and controlled load vehicle tests conducted periodically on the sections using both single axle and tandem axle trucks. Additional sets of four strain-gauge rosettes were installed in holes under the wheel path of each section to better monitor strain responses in the surface and intermediate layers, with sensors positioned near the top and bottom of each of these layers.

The controlled load vehicle testing used single-axle trucks with wide-base tires and tandem-axle trucks with dual tires, with half-axle loads of 10 kips each and tire inflation levels of 80, 110, and 125 psi, as indicated in Table 2. The loaded trucks were driven at speeds of 5, 30, and 55 mph while the sensors recorded the load response. Maximum strains were observed during testing in the summer, with temperatures at the asphalt surface ranging 86°F to 113°F, and temperatures at various depths inside the pavement in the range of 77°F to 86°F during testing.

Figure 1 summarizes the maximum tensile strain observed in the FRL at the slowest speed (5 mph). Curiously, the 13-in. section had the lowest strains, followed by the 15-in. and the 11-in. sections. This was attributed to the subgrade under the 15-in. section not being chemically stabilized, while that under the other two sections was, and thus the subgrade modulus under the 13-in. section was enhanced. This ordering of strain response also applied for the tests at 30 mph and 55 mph, though the strains were lower at higher speeds. It can also be seen from Figure 1 that the strains under tandem axle dual tire loads are 66-78% of those experienced under single-axle wide-base tires, which suggests that for a given truck load, a tandem axle with dual tires does a better job of reducing the strain on the pavement.

Results from this field test are still being processed and finalized for a future report. However, it is clear that perpetual pavement is achievable and promises real savings.

Potential upgrades

An additional component of this study examined existing pavements as candidates for upgrading to perpetual pavement status. Twenty AC pavement sites across Ohio were selected due to their outstanding performance and longevity as candidates for a forensic investigation to determine possible factors that contributed to their outstanding service. The forensic investigation comprised field distress surveys, coring, Falling Weight Deflectometer (FWD) tests, Seismic Property Analyzer (SPA) measurements, and Dynamic Cone Pentrometer (DCP) tests. In the laboratory, Indirect Tensile Strength and Resilient Modulus tests were determined from the core samples collected. Later, five of those sites were revisited to verify the previous test results.

The FWD data were used to back-calculate the layer moduli using the Evercalc 5.0 program. The tensile strain at the bottom of the AC base layer was computed with layer moduli and strain values based on a normalized 9,000-lb load applied to the pavement by the FWD, and compared to the perpetual pavement criterion.

In summary, it is now possible to design and build perpetual pavements from asphalt concrete, designed to last at least a half-century with minimal maintenance. These pavements have been successfully built and evaluated in Ohio, and further refinements and improvements to the design are continually being explored to realize the full economic potential of the concept. Not only can the design be applied to new pavements, the existence of older pavements that have proved their durability suggests that it is possible to turn some of these existing pavements into perpetual pavements by adding AC overlays.

About The Author: Sargand is Russ Professor in the civil engineering department at Ohio University and Associate Director of the Ohio Research Institute for Transportation and the Environment.