Why We Observe

By Mark Ludewig, Contributing Author

The purpose of National Work Zone Awareness Week (NWZAW) is to save lives by raising awareness of dangers in and near work sites. Established in 1999, the event is recognized by every state and takes place in April at the start of the construction season.

We have a responsibility to drive safely in highway work zones.

At any given time, work zones can account for tens of thousands of miles in the U.S. Unfortunately, where there are highways there are accidents, and too often the victims are the highway workers.

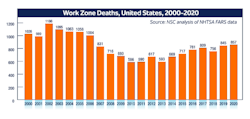

According to the latest National Highway Traffic Safety Administration (NHTSA) data, more than 800 people were killed and over 44,000 injured in work zone crashes in 2020. Alarmingly, work zone deaths have increased 46% since 2010, signaling the need for increased motorist awareness of the issue and new strategies to combat distracted driving habits.

The number of fatalities is not the only factor to consider. The financial costs of highway work zone accidents are far too often overlooked.

Our industry’s workers suffer approximately 27,000 first-aid injuries and 26,000 lost-time injuries a year at a total cost of nearly $2.5 billion, and motorists suffer approximately 52,000 property-damage-only accidents at a total cost of $6.2 billion a year due to highway work zone accidents, according to a study from researchers at the University of New York at Buffalo.

In the U.S. in 2017 alone, 94,000 vehicular accidents occurred in work zones, according to a report published in the “International Conference on Transportation and Development 2020.” The total economic impact of these crashes was estimated at nearly $17.5 billion—a figure which includes costs such as medical bills, lost wages, and property damage.

National Work Zone Awareness Week is an opportunity for the public to show its appreciation for highway workers. While they may not directly interact with the people who keep our roads safe and in good repair, it is important to recognize the risks work zone workers take in their daily tasks.

This week also aims to raise awareness of the safety measures employed by highway construction companies. These include designing safer work zones and training employees to recognize and respond to hazards. Companies are also encouraged to emphasize the importance of proper personal protective equipment such as high-visibility clothing.

The best defense against dangerous driving habits remains a properly designed and implemented work zone staffed by trained and certified safety professionals that also leverages the latest technologies. In our next article, we’ll take a closer look at the tools taking safe traffic control to the next level, including a new generation of smart devices that can automatically alert workers to danger.

By respecting highway construction crews, observing signage and obeying traffic laws in work zones, we can all help reduce injuries, fatalities and medical costs resulting from accidents. For workers on the frontlines, it is their best chance to return home safe and healthy at night. R&B

Mark Ludewig is the vice president of Safety for AWP Safety.