Technological advances in the winter maintenance field found to reliably increase safety

When I was in high school, I drove around in a 1976 Chevy Nova with a manual transmission and a cassette player blasting some form of ‘80s rock.

Now my personal vehicle plays music off my phone with a Bluetooth connection, and it has a computer in it that is so advanced it will deploy the brakes on my behalf if it senses a danger. Technology is a race car that never stops and only gets faster.

The field of winter maintenance is no exception to the same forces that turned my cassette player into something you can find in a museum. When I first started in winter maintenance as an equipment operator, the plows were very basic; just a few levers to choose from to control the plow were all that we had. Now they are equipped with wireless devices, tablets that talk to you, endless tech gadgets, and they speak to the cloud. The main driver for these innovations, and their resulting success, is the safety of the traveling public and ever-shrinking government maintenance budgets. What we once thought was a wild dream is moving closer to becoming a standard in agencies throughout North America.

This article will walk through a few of the advances in technology that the winter maintenance field has tried, tested, and found to reliably increase safety and save money.

Expandable, wing, and tow plows

Despite all the advances in technology, sometimes your grandpa’s tools are still the best ones in the shop. The snowplow remains that tool when it comes to winter maintenance as the most efficient piece of equipment for removing snow from roadway and runway surfaces. However, this trusty machine has evolved and adapted to become over twice as efficient when coupled with new technology like wings, expandable plows, and tow plows. Not only are today’s snowplows more efficient, they are also more forgiving to the operator. Ergonomics was a passing thought in days past, but today our operators can enjoy infinitely adjustable air ride seats and air ride cabs to make long hours spent on the job more tolerable.

On average, a typical snowplow has a 12-ft edge impacting the ground, clearing roughly 10 ft of road surface in a single pass, but new technologies put more edge on the ground. Snow wings can be added to plow trucks that handle all kinds of routes. They come in a variety of sizes and configurations that are fixed onto pieces of equipment, all with the intent of clearing more road surface with one vehicle. There are front-mount, mid-mount, and rear-mount wings that can be placed on either side. Expandable plows are similar to snow wings in that they clear more area with one operator and one truck. The advantage of expandable plows, however, is that the operator can extend the plow out as needed to cover an increasingly larger area and return it to its original dimensions when needed. The tow plow can increase the surface area plowed even more dramatically through a trailer that is pulled behind a plow truck with a 26-ft moldboard that can clear up to an additional 15 ft of area in one pass—taking snow clearing efficiency to another level entirely.

All of these additions to a basic snowplow configuration allow more flexibility and greater efficiency in winter operations. While these implements add value, they do complicate the tasks we require of our operators. It is essential to give these professionals the training needed to perform their jobs efficiently and safely.

Long-life cutting edges

Gone are the days when mild steel expendable edges that had to be replaced after each storm were our only choice for cutting edges. These days our edges allow operators to spend more time plowing and less time in the shop changing edges. There are numerous brands and manufacturers in the snowplow cutting edge market. There are many combinations of steel and carbide, steel and rubber, rubber with carbide inserts, rubber with carbide embedded, extreme hardened steel, rubber and ceramic … the list goes on and on.

Each of these edges has a specific application to which it is best suited. Finding the correct one for your needs takes time and effort, but vendors are happy to help you make the correct decision. The biggest efficiency with long-life cutting edges is that it allows operators to spend more time on the road serving the public instead of under a truck dripping with snowmelt. Incredibly, many of these edges do not just last multiple shifts, they last multiple seasons. While the initial cost is substantially higher, the overall life-cycle cost of the blades is comparable or less. Top that with happier operators and a higher level of service to the public, and it is hard to go wrong with long-life cutting edges.

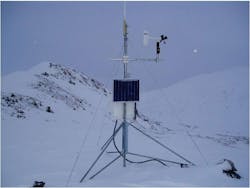

RWIS and mobile sensors

A critical component in deciding how to respond to a unique winter event has always been weather data. The difference now is the amount of data we are able to use to inform our decisions. Road Weather Information Systems (RWIS) are a fixed-point sensor array that can provide ambient temperature, dew point, relative humidity, wind speed and direction, surface temperature, subsurface temperature, road friction, precipitation occurrence, and type of precipitation. An additional feature of many RWIS sites is a live and recorded camera view. Where we used to drive the road and get a look with our own eyes to determine conditions, now we can look at the data and visuals from the office. This is an invaluable tool in effectively managing winter storm events.

While an RWIS site can provide highly accurate fixed-point data sets, a recent advancement has been to add sensor arrays to supervisor vehicles and plow trucks to provide data on an entire route system. These sensors often provide fewer data options (typically ambient and pavement temperatures, dew point, and possibly road friction), but this additional information combined with fixed-point data is critical to true-up forecasts and increase accuracy.

MDSS

“Go” or “no-go” is one of the most difficult decisions we have to make in our snow operations. Should we put extra operators on call? Should we apply liquids ahead of the event? Do we need our fleet ready over a holiday? Where in the system will we need to focus our attention? An accurate Maintenance Decision Support System (MDSS) is another incredibly helpful tool to aid in making these tough calls.

Every MDSS system looks different in type and format, but common to all these systems is that they make sense of the data gathered by RWIS, mobile sensors, and other publicly available weather data to provide not only specific precipitation forecasts, but a road weather forecast as well. Hyper-accurate localized road weather (pavement temperature and possibly friction) forecasts are critical to effective winter operations. This system is not a replacement for the skills and experience of an operations manager, but is an essential supplement to that skill set. I know from personal experience that even in combination, those tools are not infallible. However, there is no doubt that we can make the correct decision more often with an effective MDSS system than without, which means saving time and precious funds to better serve the public.

Route optimization

Efficiency in winter operations is more critical than ever before. Public expectations for road conditions during and after an event have increased tremendously, but resources to deliver on those expectations have become more scarce. We are expected to perform optimally at all times, and even then it is difficult to meet expectations. Plow routes are built from an agency’s snow plan that has been approved by the elected body we serve. Route optimization seeks to make snow operations as efficient and transparent as possible through technology.

We used to make plow routes with a map and a highlighter, and that process was often genuinely effective at creating efficient routes. More recently, however, commercially available planning services have been brought forward to make those routes even better. Route optimization consultants look at operations as a whole and break down processes based on entity resources and configurations, then provide suggestions for improvements to the plan. Going a step further, tablet screens and voice commands can provide turn-by-turn guidance to the operator in the cab, allowing the operator to be more focused on operating the 25 tons of steel at their control instead of following a map or list.

The backbone of a route optimization system is an Automatic Vehicle Location (AVL) system used to track and monitor equipment in a fleet. AVL opens the doors to many opportunities to communicate operations to the public we serve. Many agencies today are publishing real-time information on equipment locations and plow cameras through public facing websites, commonly called “Where’s my Plow?” or “What is the Plow Operator Seeing?” This information helps travelers visualize real-time road conditions to help them decide when to travel, when to delay travel, and when to allow extra time due to adverse conditions. This increases safety for the public and provides more transparency about an agency’s operations.

Liquids

While many agencies still use salt to enhance winter maintenance, liquid brine use is also becoming an industry standard. The idea that liquids could enhance winter maintenance can be, at first look, counterintuitive to the concept of keeping winter roads as clear as possible. However, the use of a chemical suspended in a liquid for an instantly usable brine that prevents the bond of snow and ice to a surface makes tremendous sense. With brine, we use less chemicals than with straight salt, we provide a higher level of service during an event, and cleanup after an event is easier and more effective with less snow and ice bonded to the pavement.

Many of the technological advances discussed previously such as an accurate MDSS system and fixed RWIS and mobile sensor arrays directly support the use of liquids in winter maintenance. Now we are more confident about when liquids should be applied so they can be most effective. When using these technologies in combination, the benefit in all phases of winter maintenance can greatly improve services delivered to the public.

Using technology to meet public expectation

Winter maintenance in its simplest form can keep society functioning during the winter season. Much of North America, and in fact much of the world, is impacted by winter weather. Even in the worst winter events, the public expects that daily life will continue to function, that they will be able to drive to work with minimal delay, that there will be food on the grocery store shelves, that schools will be open, and that they will have the freedom to move about as they please. Proper response to winter events not only allows those expectations about daily life to be fulfilled and saves society billions of dollars in lost revenue and increased costs, but, most importantly, it saves lives.

Weather events always have the upper hand regardless of the tools at our disposal. However, as technology in winter maintenance continues to race on, and the expectations of the public keep right along with it, we as a profession will be able to build on the successes we earned with our old tools to become even better with these new ones. I may be listening to music through a Bluetooth connection these days, but you will still hear me blasting Bon Jovi.