The Winona Bridge rehabilitation project preserves a historic Minnesota span

Spanning the mighty Mississippi River, the historic Winona Bridge recently underwent a rehabilitation that represents a balance of historic bridge preservation standards and modern bridge design provisions—notably provisions related to internal redundancy.

The success of balancing federal laws that provide for the protection of historic bridges with careful consideration of the details and means of providing internal redundancy has provided 50 years of additional design life to this crucial Minnesota structure. What was once considered a strong candidate for removal and replacement evolved to include the most complex historic truss bridge rehabilitation ever undertaken by the Minnesota DOT (MnDOT).

The Winona Bridge was originally constructed in 1942, subsequently rehabilitated in 1985, and eventually closed for emergency repairs in 2008 after inspections revealed severe deterioration to gusset plates on the approach span deck trusses. Although the bridge is beloved and serves as an enduring symbol for the city of Winona, Minnesota, the 77-year-old structure had deteriorated significantly over the years. Pack rust had accumulated on key truss members, section loss was prevalent, and the increasing deterioration of the deck truss approach spans caused MnDOT to restrict the maximum truck weight on the bridge through load posting.

Preliminary design studies were initiated in 2009 to evaluate various alternatives for rehabilitation, in accordance with the National Environmental Policy Act (NEPA), which requires consideration of preservation of historic resources. Various alternatives were studied that included construction of an adjacent temporary bridge that could be used to divert traffic during the major rehabilitation. Ultimately, it was concluded that construction of an adjacent new permanent bridge would be more cost-effective over time. The new adjacent bridge was designed to carry two-way traffic during the rehabilitation, along with a new permanent pedestrian trail. The Winona crossing would benefit over the long-term with traffic improvements provided by the completed four-lane configuration.

In 2008, the Minnesota Legislature enacted an ambitious Trunk Highway Bridge Replacement and Improvement Program under Chapter 152 legislation. One element of this legislation was including redundancy on significant state-owned bridges. However, the details of successfully incorporating redundancy into historic truss spans needed careful evaluation during the design process to ensure that a “no adverse effect” determination could be achieved.

In development of the Final Design Criteria for historic truss bridge rehabilitation, the team aimed for an ambitious goal—completely rehabilitating the bridge to resist modern permit loads, reconstructing the approach spans, rebuilding the deck, and adding internal redundancy to comply with the intention of state statutes, all while avoiding an adverse effect to the historic character-defining features of the structure. By modernizing the structure, the Winona Bridge successfully became the first through-truss bridge in the Midwest to have all its fracture-critical elements made internally redundant.

Past and present

The Winona Bridge is the only remaining pre-1946 cantilever through-truss bridge in the state, and it played a central role in sustaining the economy of Winona and facilitating the flow of defense materials during World War II. Its historic significance is evident by its eligibility for listing on the National Register of Historic Places.

Today, the bridge continues to be critically important to the local economy, accommodating approximately 12,000 cars every day. Many of these drivers are Minnesota and Wisconsin residents commuting to jobs at employers headquartered on both sides of the Mississippi River. This heavy daily traffic also includes trucks delivering products and other commercial merchandise to Minnesota and Wisconsin locales.

Just how vital the bridge’s role is became clear back in 2008, when MnDOT shut down the bridge to all traffic for 11 days after a routine maintenance inspection triggered an emergency repair/replacement project. The Winona Area Chamber of Commerce studied the results of the closure and estimated the regional economic impact to be in the millions of dollars. During the shutdown, Winona Bridge users were forced to make detours of at least—at least—60 miles round-trip to other Mississippi River crossings. Moreover, many residents of Wisconsin border counties who depend on a Winona-based provider for first-call ambulance services faced an undue burden in this respect.

Planning & preliminary design

For the planning and preliminary design phase, MnDOT assembled a project design team, led by MnDOT District 6 project management and SRF Consulting engineers to work together with the Winona community to develop the project, with oversight by the Federal Highway Administration, MnDOT’s Cultural Resource Unit, the State Historic Preservation Office (SHPO), and MnDOT’s Bridge Office. As evaluation of rehabilitation alternatives is integral to Section 106 of the National Historic Preservation Act, MnDOT also contracted with project historian Mead & Hunt to guide the development of rehabilitation alternatives. The preliminary design phase concluded with development of the Environmental Assessment (EA) in 2013.

The Winona Project Design Team also formed a Visual Quality Review Committee, with representation from local stakeholders to obtain input from the community for development of a Visual Quality Manual for the project. To help guide the sensitive process, a vision statement was formed, with input from the community and project historians to help guide the final design process: The Winona Bridge should reflect the current era while respecting the past. The existing bridge is a visual icon for the city, and so the new bridge should defer its prominent visual presence. The new bridge should celebrate the river’s natural beauty and the cultural history of Winona that is intertwined with the river. Together, the two bridges should symbolize a welcoming gateway to beauty, culture, and prosperity.

A new procurement method

In 2012, the Minnesota Legislature provided legislative authority to MnDOT to develop 10 projects using the construction manager/general contractor (CMGC) project delivery method. Evaluating the procurement options, MnDOT selected this project delivery approach, which provided many advantages to project delivery with input from the contractor during the final design phase. This was the first time MnDOT had used CMGC. This method of collaborative design and construction allowed for many benefits—fostering innovation, allowing flexibility, improving cost control, reducing change orders, providing higher quality design, reducing risk, and optimizing schedules.

Using CMCG, MnDOT engaged Ames Construction as the prime contractor and Michael Baker International as the lead designer, in addition to HNTB as the peer reviewer. The early collaboration between MnDOT, Ames, and Michael Baker shaved months from the construction schedule, gave MnDOT greater control over project decisions, and allowed the team to work closely to solve the problems that the project presented. The biggest advantages realized using the CMGC process for this complex rehabilitation were that contractor collaboration during the final design process led to reduced risk and much better cost certainty, since constructability reviews were completed with the 30%, 60%, and 90% design phases. This resulted in nearly zero cost growth post-letting, due to minimal change orders during construction.

Truss rehabilitation

With the final design criteria established for historic truss bridge rehabilitation, the goal of rehabilitating the structure was underway, with much work to complete. The project’s success hinged on strengthening the through-truss to remove the current load restrictions, extending the service life by 50 years, and adding internal redundancy retrofits to the bridge’s fracture-critical elements in accordance with the state’s Chapter 152 legislation, all while maintaining compliance with the Secretary of the Interior’s Standards to avoid a NEPA Section 106 violation.

The team evaluated numerous approaches to rehabilitating the existing through-truss that would satisfy strength, redundancy, and historical requirements. Truss tension and compression members were analyzed, and it was determined that installation of steel plating or high-strength post-tensioning bars would adequately reinforce members that required it.

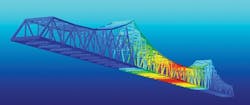

To determine how the bridge would react to modern vehicular demands, both 2-D and 3-D finite element analyses were used to analyze the bridge for Strength Limit State, Extreme Event Limit State, and construction-loading conditions. Dozens of iterations were conducted in order to evaluate numerous scenarios to determine how many truss members would be visually impacted from a historic perspective. This allowed the design team and the cultural resources team to find common ground.

To study extreme event member fracture limit states, the team analyzed dozens of fracture-critical truss members to determine if any retrofits would be required to satisfy internal redundancy design criteria. The theoretical instantaneous pulse-load fracture case was considered, in addition to a post-fracture case. In addition, a refined 3-D finite-element analysis was integrated into the conventional 3-D finite-element model of the through-truss to evaluate how the post-tensioning bars would engage in an Extreme Event Limit State, prior to damaging adjacent structural members. The analysis focused on the theoretical fracture of a diagonal tension member retrofitted with high-strength post-tensioning bars near the quarter point of the main span over the river. Thanks to this innovative application of 3-D modeling, it was determined with confidence that the high-strength bars would function as expected and provide the internal redundancy to the rehabilitated bridge, thus complying with modern bridge design code provisions and the intentions of the Chapter 152 legislation.

Additional complexities soon followed. After a vessel impact analysis and underwater inspection determined that the bridge’s timber piles would not properly resist the impact of modern barge collision loads, the rehabilitation team designed and constructed a unique strut system to link the original structure with the new parallel bridge to assure that they would share the impact of any barge collisions. Struts were inserted between existing Piers 18 and 19 and the piers on the newly constructed concrete box girder bridge. This solution allowed the existing timber pile system to be used without major modification, saving the significant costs of foundation strengthening.

It was determined that the existing deck truss approach spans were beyond repair, and so all the bridge’s approach spans were rebuilt. The new steel deck truss system that was constructed for the approach spans maintains the structure’s historic character—and also stayed within budget. Approach spans also included prestressed concrete girder spans and a complex post-tensioned flat slab designed by Kimley Horn. Additional project highlights included installing a state-of-the-art uplift resistance system that incorporated the truss end spans and adding new TL-4 crash-rated railings in accordance with historical standards.

The underwater inspection also revealed some signs of scour, erosion of supporting soil that, if allowed to continue, could lead to pile failure. To avoid future scour, geobags and riprap circling the pier for 40 ft were installed.

Looking to the future

Construction began in 2016, with a schedule for completion of Dec. 1, 2019; however, thanks to the team’s extensive collaboration and innovative solutions, the 2,291-ft bridge opened to traffic five months early on July 1, 2019. In the end, the extensive rehabilitation of the 77-year-old historic Winona Bridge increased its capacity to resist modern vehicle loads, added 50 years of service life, provided internal redundancy to all fracture-critical members, strengthened the foundations to resist modern barge and scour loadings, and maintained the iconic bridge’s historic features.