Web Exclusive: Quick scan

In April 2010, the Illinois Department of Transportation (IDOT) and the Illinois Center for Transportation (ICT) published a research document titled Evaluation of 3-D Laser Scanning for Construction Application. The objective of this research was to study how 3-D laser scanning technology could be utilized in evaluating pay quantities in IDOT projects such as earthwork, gravel and pavement thickness, and pavement roughness, as well as documenting archaeological investigations.

The finding of the initial research project suggested that 3-D laser scanners could be a cost-effective way to aid in construction operations. Although the initial phase of the research project sought to identify practicums in construction operations, it was quickly realized that the 3-D laser scanners could be beneficial in additional surveying uses such as intersection, bridge girder and bridge deck surveys.

These additional survey uses allow IDOT to use innovative technology to carry out its mission as efficiently as possible while enhancing worker safety and creating fewer traffic delays.

In October 2013, IDOT embarked on a research implementation project to study the pros and cons of using 3-D laser scanners versus traditional methods of surveying using a three-person crew and a total station. IDOT procured three scanners, each one distributed to different offices—District 3 in northeastern Illinois, District 8 in southwestern Illinois, and the Central Bureau of Operations, Aerial Surveys Unit, in Springfield.

The methodology of the implementation project was straightforward: identify projects in which a 3-D laser scanner could be used, followed by a comparison of time wherein personnel are exposed to traffic versus conventional methods. Survey crews would perform a full survey using conventional methods from start to finish. Then, the same crew would perform another survey utilizing the 3-D laser scanner from start to finish. Personnel hours for each task were documented for field time, records research and data processing.

The exception to this process was for the measurement of various components of bridges under live traffic. In these cases, it was apparent that the 3-D laser scanner was both the most effective and safest alternative to traditional methods, as it allowed traffic to flow normally while the survey was performed by the scanner off to the side of the roadway.

In June 2016, the Central Bureau of Research facilitated a demonstration, led by the survey team from District 8, on using the 3-D scanner for intersection surveying. Additional staff from District 3 Surveys, District 5 Operations, Central Bureau of Operations, Central Bureau of Construction, and the Illinois Capital Development Board Professional Services Section attended. An intersection in Springfield was surveyed, allowing attendees to see how efficient the actual surveying can be, and the types of data that are collected. IDOT also created a demonstration video.

The IDOT implementation study’s technical review panel met after the demonstration to discuss their recent experiences with the scanners and to identify past and future projects that could be evaluated using the 3-D laser scanner.

Photo of IDOT maintenance crews assessing damage to a struck overpass bridge on U.S. 34. Photo courtesy of IDOT.

Case studies

U.S. 50 in Carlyle, Ill.

In April 2015, IDOT survey crews in District 8 were tasked with completing an existing-conditions survey of resurfacing and ADA improvements on U.S. 50 from 3rd to 11th Streets in Carlyle. A full topographic survey was requested for the ADA ramps at nine intersections.

Conventional ground survey methods for the field phase required 309.5 hours of field work to collect the necessary measurements. An additional 64 hours of processing was required to produce finished CAD files, resulting in a total time of 373.5 hours.

Using the laser scanner survey methods, the crew was in the field for a total of 194 hours. Processing of the scanner data required 121 hours to produce finished CAD files, resulting in a total time to collect data and produce a finished CAD document of 315 hours.

While the post-processing time required for the laser scanner method was approximately double that of the conventional survey method, the total time to complete the project was reduced by 58.5 hours; most of the time savings was attributed to less exposure time of IDOT staff to traffic. Conventional survey methods placed personnel near or in traffic for 294 hours; however, the laser scanning method placed personnel near traffic for 194 hours. The exposure of the work crew was decreased by 100 hours, or approximately 34%, using the laser scanning equipment.

Damaged bridge girder with a 4-ft slice of a point cloud scan. Source: FHWA-ICT-10-068 Report

Intersection improvements near Belleville, Ill.

In June 2016, IDOT District 8 crews surveyed the intersection of S.R. 158/S.R. 177 and Plum Hill School Road near Belleville. The project intent was to install a westbound left-turn lane on S.R. 158/S.R. 177.

Conventional ground survey methods for the field phase required 80 hours of fieldwork to collect the necessary measurements. Once that information was returned to the district office, another 26 hours of processing was required to produce finished CAD files, resulting in a total time of 106 hours.

The 3-D laser scanner surveying method placed the crew in the field for 51.5 hours to acquire the scans, as well as lay out the benchmarks and control points for the designers and consultants. Processing of the scanner data took 53 hours to produce finished CAD work, resulting in a total time of 104.5 hours.

The use of laser scanning equipment on this project shortened the overall project time by only 1.5 hours, with the post-processing time required for the laser scanning method being twice as much as that required for the conventional survey method. The larger benefit was that while conventional methods placed personnel in or near traffic for a total of 80 hours, the laser scanning method placed personnel in or near traffic for only 51 hours. The traffic exposure of the work crew was decreased by 29 hours, or approximately 36%, by using the laser scanning equipment.

An important part of the implementation project has been gathering feedback from the surveying crews. Rick Porter, chief of surveys in IDOT District 8, was an early adopter of the 3-D Laser Scanning technology.

“District 8 has been using the 3-D laser scanner on ADA ramp surveys and intersection surveys,” Porter said. “The implementation of the work flow was definitely challenging. The new process was met with skepticism and excitement—skepticism, because you wonder if it really is that accurate; excitement, because it leaves little to the imagination. Moving forward, we foresee the scanner as a useful survey tool in addition to substantially limiting the amount of time staff spends in high traffic situations.”

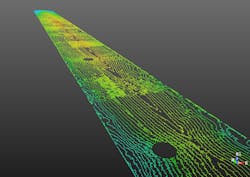

Bridge deck scan of I-57 over Kankakee River. Photo courtesy of IDOT.

I-57 bridge over Kankakee River

The I-57 bridge across the Kankakee River spans 540 ft and consists of two separate superstructures—one structure for the northbound lanes of traffic, and another structure for the southbound lanes of traffic. After construction, IDOT crews observed that the I-57 bridge deck was experiencing drainage problems and water ponding after rain events. As a result, IDOT designers wanted to accurately survey the bridge deck to identify its low spots and flat areas to determine where to place additional deck drains.

In July 2016, while utilizing the laser scanning equipment, the bridge structures were surveyed while regular traffic flow was maintained across the bridges. With only one person collecting the data, each structure required seven scans (setups) per structure. A one-person crew was able to set up the scanner and survey the bridge decks from a safe distance away from the traffic lanes. Each structure took approximately two hours to scan for a total field time of approximately four hours.

The 3-D laser scanning equipment was able to create a contour surface map of the bridge decks in 0.02-ft intervals.

The accuracy of the contour intervals allowed designers to clearly identify low spots in the bridge deck. Using traditional surveying methods would not have been possible at such high levels of accuracy under live traffic conditions. Traditional survey methods could only have been used to get the desired accuracy by shutting down both lanes of traffic on each structure, and diverting or detouring traffic for an extended period of time.

Utilizing the 3-D laser scanning equipment on this project provided a multitude of benefits: a high level of data accuracy, a brief time period of personnel exposure to traffic hazards, minimization of traffic flow disruption and timely execution of the project to move forward coupled with a solution for safety improvement to the traveling public.

“The scanner gave us the ability to identify the low spots under live traffic conditions,” said Peter Burbulys, PLS, acting chief of surveys for IDOT District 3 who performed the I-57 bridge scan. “This technology will revolutionize the way IDOT surveys hard surfaces, giving us the ability to take pavement measurements under live traffic conditions. It will probably bring about the biggest change to conventional survey methods since GPS, while saving lives.”

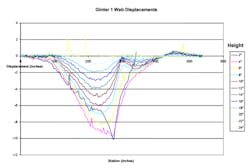

Web displacement curves calculated from point cloud scan. Source: FHWA-ICT-10-068 Report

Scanning bridges and structures

Overpass structures are frequently struck by large trucks carrying oversized equipment. As part of this ongoing research project, IDOT’s Central Bureau of Bridges and Structures is utilizing the laser scanning equipment to obtain detailed and accurate scans of multiple overpasses that are frequently struck by vehicular traffic. To date, IDOT has scanned 15 bridge superstructures that are routinely hit by trucks, and are continuously scanning more structures to include in a database of baseline scan information. This information will be used for a comparison of before and after conditions to quantify damage to the structure, determine potential safety issues, and identify repair requirements. Currently, IDOT maintenance crews use bucket trucks and have traffic control set up to measure deflections and damages by hand. Depending on the size of damage and the point of impact, this data collection can take at least two or three working days with a three-person crew.

In contrast, a one-person crew can erect a scanner off the side of the roadway and can, depending on traffic volume, either completely eliminate the need for traffic control or greatly reduce the lane closure. In some cases, a bridge girder scan could be completed in as little as 15 minutes. In most cases, bridge maintenance engineers need 2 ft of measurements on either side of the point of impact, as well as displacement measurements of the webbing.

Because a point cloud is gathered from the scanner, this data can be extrapolated and plotted in the safe environment of an office setting and not hand-measured in the field. These displacement measurements and timely delivery of that data are critical to structural engineers who need to analyze any reduction in structural capacity or adjust posted load ratings to the bridge until repairs can be made.

“The 3-D laser scanner is going to help us be very effective and expedite our processes,” said Victor Veliz, IDOT’s unit chief of bridge investigations and repair in the Central Bureau of Bridges and Structures. “In addition, the laser scanner will greatly reduce the amount of time that our maintenance personnel and contractors are exposed to work-zone traffic.”

The use of 3-D laser scanners has garnered attention from all IDOT districts, which are continuously looking for ways to improve their work efficiencies while increasing worker safety.

“Safety is a top priority here at IDOT, and 3-D laser scanners are helping us increase safety for our workers,” Illinois Transportation Secretary Randy Blankenhorn said. “By using this technology, we are reducing the need to have our employees near moving traffic, plus these scanners provide detailed survey information that is helpful for our planning and outreach purposes.”

IDOT intends to purchase additional 3-D laser scanners in the future so that each district has a machine.

Overall, the 3-D laser technology has demonstrated its effectiveness by reducing the exposure of IDOT personnel to traffic hazards, improving worker safety in the field, and minimizing disruption to the traveling public. The final report of the implementation project is scheduled to be published by April 30, 2018.