WEB EXCLUSIVE: Right-sizing roundabouts

Your community is demanding your elected officials take action. That congested all-way stop intersection in town is a nightmare during the evening commute. Your elected board or council members agree. But you are forced to remind your board and their constituents that resources are not available to improve the intersection. Sound familiar? Hundreds of transportation agencies across the country face this issue every day: how do we stretch limited resources so matching dollars can be used to leverage federal and state aid to address these needs?

An agency in Michigan found a right-sized solution to address their congestion issues without breaking the bank. Meet the mini-roundabout, the newest member to the roundabout family in the United States.

Mini-Roundabouts

A mini-roundabout is not simply a small or compact roundabout. Rather, it is defined as a roundabout with a fully-mountable central island. The mini-roundabout was originally developed in the U.K. as a lower-cost alternative to normal roundabouts. It is commonly used in the U.K. as a right-of-way control device, similar to all-way stop control, but more efficient. Mini-roundabouts provide most of the benefits of normal roundabouts while keeping the existing intersection footprint small. A smaller design footprint yields reduced right-of-way needs, a lower bid price and less time needed to construct the roundabout.

By definition, a mini-roundabout in the U.K. must have a domed central island with a maximum height of 150 mm (6 in.) and maximum diameter of 4.0 m (13 ft). This limits mini-roundabouts to small intersections. Implementing mini-roundabouts at larger U.S. intersections requires that the central island size be increased to provide effective speed control. Mini-roundabouts are usually constructed with a low-profile curb and gutter around the perimeter of the center island, or are curb and gutterless with a gently domed central island. This design detail keeps the overall height reasonable, allowing over-tracking by tractor semi-trailers and lowboys without bottoming out.

A mini-roundabout in Bracknell, U.K. Image source: GHD/Ourston

A recent mini-roundabout in Bel Air, Maryland.

Often with intersection design, capacity and efficiency is emphasized at the detriment of safety and cost. There are three main factors that contribute to this issue: traffic forecasts sometimes overestimate traffic growth and indicate more lanes will be needed sooner, capacity models can also be overly “conservative” and indicate failure of a design sooner, and design horizons can be inappropriately long for the project or site context.1 In the case of roundabouts, being overly “conservative” in one or more of these areas can lead to a design that is more expensive and potentially less safe.

There are several ways to reduce construction costs for roundabouts. Using a smaller design vehicle (which is typically a large truck like a tractor semi-trailer), reducing outer curb and gutter and underground storm sewer, keeping the approaches to the roundabout on alignment as much as possible, and crushing and shaping the existing pavement so that it remains in place as base material can all be successfully utilized to lower construction costs. It is here that the mini-roundabout holds particular promise. Large commercial trucks, fire ladder trucks and farm equipment can over-track the fully-mountable central island and make direct left turns instead of traveling counterclockwise around the perimeter, enabling the roundabout to more closely adhere to the footprint of the original intersection.

A tractor semi-trailer traveling around the central island of a roundabout.

A low-cost roundabout is not necessarily a mini-roundabout. Traditionally sized normal and compact roundabouts have signs and landscaping in the central island to increase visibility and cut off view of oncoming vehicle headlights. This is especially important during periods of poor visibility. A challenge with mini-roundabouts, because the central island is fully mountable, is to ensure they can be readily seen (another challenge can be winter maintenance). Therefore careful design is needed in rural or suburban areas where approach speeds are often high. Mini-roundabouts also need to be well illuminated and located where they will be expected by approaching drivers.

Most mini-roundabouts constructed to date in the U.S. have been at busy intersections in villages or as part or rural traffic-calming schemes. They are proving to be ideal as a replacement for all-way stop control, especially when traffic signals are not warranted. Experience is showing they can work safely where the posted speed limit is 45 mph if approach speeds are reduced prior to entry.

Case study: Textile Road in Washtenaw County, Mich.

Washtenaw County is located west of Detroit, Mich. Its population is 354,000 and the county seat is Ann Arbor, home of the University of Michigan. The County has 66 all-way-stop intersections. Many of them are congested and meet traffic signal warrants, with some having up to 5-minute delays during peak periods. Many of the intersections are on the unfunded project list.

A typical morning queue at an all-way stop intersection in Washtenaw County. Image source: Washtenaw County Road Commission

Two particularly congested intersections are on Textile Road in Ypsilanti, at Stony Creek Road and at Hitchingham Road. Textile Road is a busy commuter route with a posted speed limit of 45 mph. Both Stony Creek and Hitchingham Roads have 55 mph speed limits.

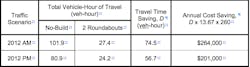

An economic analysis based on total vehicle hours of travel was undertaken by the Federal Highway Administration (FHWA) to calculate cost/benefit if the two intersections were to be converted to compact roundabouts. Using an adjusted 2013 value of time of $13.67 per hour, it was determined that the user cost savings during the a.m. and p.m. peak periods alone could recover the construction cost.2

Note: The adjusted 2013 value of time = $13.67/hour. The cost savings calculation is for peak hours over 260 days/year. Image source: Wei Zhang, Ph.D., P.E., FHWA Intersection Safety R&D Program Manager

It was decided during the design phase that mini-roundabouts would be an ideal alternative because they keep the intersection footprint small. This would save on costs and minimize impacts to adjacent properties.

Construction began in mid-June 2015 and was completed two months later. Both intersections were closed to traffic during construction. A crush and shape operation was used to reduce construction costs and the time needed to build the mini-roundabouts. All crushed material remained on site and was utilized as base material. No new aggregate was placed on the existing roadbed once it was shaped. Six inches of Superpave hot-mix asphalt was placed over the compacted surface. Furthermore, no storm sewer was utilized as part of the design. Concrete spillways with open channel ditches were utilized to address drainage needs without the expense of enclosed drainage features.

One of the mini-roundabouts under construction. Image source: GHD/Ourston

Each central island has a gentle domed profile without the use of curb and gutter. The height is 6 in. (150 mm) and the diameter is 50 ft (15 m). There are long splitter islands on the high-speed approaches to alert drivers to the presence of an intersection ahead so they begin to reduce approach speed well in advance. The culture of yielding has existed for many years elsewhere in the world where mini-roundabouts are being used. In the U.K., for instance, yield signs are not posted on conventional roundabouts since it is understood that roundabouts mean yield at entry to circulating traffic. In the U.S., transportation professionals are taking precautions to ensure that the geometry of the intersection approaches elicits the necessary speed reduction to make yielding the obvious driver choice at a roundabout entry.

The final construction cost of the two mini-roundabouts was $808,000, or about one-third the estimated cost of two normal roundabouts. They can comfortably accommodate school buses and medium-sized trucks. The largest standard semi-tractor-trailers can over-track the central island and semi-mountable curbs around the outsides where necessary.

Overview of the as-constructed mini-roundabouts on Textile Road. Image source: Google Maps

Close-up of the (westerly) Stony Creek mini-roundabout. Image source: GHD/Ourston

Close-up of the (easterly) Hitchingham Road mini-roundabout. Image source: GHD/Ourston

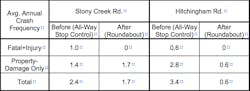

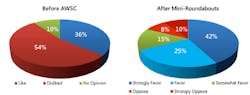

By three important measures the mini-roundabouts can be considered a success: they have all but eliminated peak hour congestion at the two intersections, they have reduced motor vehicle crashes and public opinion has been quite favorable.

Before (all-way stop control) and after collisions at the two intersections. Image source: Washtenaw County Road Commission and VHB

Before and after public opinion of the mini-roundabouts. Image source: Washtenaw County Road Commission and VHB

Conclusion

Roundabouts can have very significant safety and congestion-relief benefits. These benefits are best realized when roundabouts are well-designed, especially at this (still) early stage of roundabout implementation in the U.S. However that does not mean roundabouts have to be expensive.

Transportation professionals have a duty to the public to spend taxpayer funds wisely. With the Textile Road project, Washtenaw County was “right sizing” a solution to address traffic congestion in an effort to be fiscally responsible with limited resources. Roundabouts do not need to be gold-plated to be effective. Can we save more lives with one $2.5M roundabout, or four $625K compact or mini-roundabouts?

----------------

1 Scott Zehngraff, P.E., GDOT Assistant State Traffic Engineer

2 Wei Zhang, Ph.D., P.E., FHWA Intersection Safety R&D Program Manager