Routes need to be carefully calculated for mining trucks

When mining trucks and steep, winding roads meet, more emphasis must be placed on safety.

Around the world, mining companies face enormous time and financial pressures to get the natural resources out of the ground. If a truck tips over on the way from the mining site to the processing plant, the consequences can be serious. With today’s road-design software technology, that kind of mistake is preventable.

Vale S/A is one of the biggest mining companies in the world and they operate several mines in Minas Gerais in the eastern part of Brazil. In addition to iron ore, they have nickel, copper, coal and manganese mines throughout the country. With hundreds of trucks making trips to the various mines daily, the route they take must be planned carefully, and Vale S/A relies on AutoTURN by Transoft Solutions to plan the vehicle paths. The engineers and planners need to know how vehicles like the Mercedes 6x4 truck loaded with iron ore will behave when faced with sharp turns and changing terrain.

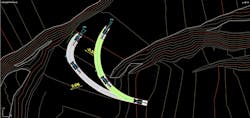

Antônio Carlos De Miranda Francisco, one of Vale S/A’s production engineers who help design roads for the mines, began using the software in 2013 to perform investigative analysis when a Mercedes Benz 6x4 truck tipped over leaving the Itabiritos Pico mine area. The accident occurred at night, when the operator of the truck entered a roundabout too fast where the maximum recommended speed is 17 km/h or less. In addition to the roundabout investigation, he has used the software to plan road geometry around the Itabiritos Peak Complex.

“It was a question regarding the speed of the operator at the time of the accident,” said Francisco. “The safety committee approached us to help them identify the radius of the trajectory performed by the truck in order to then calculate the average speed. The starting point of the work was to identify the correct position of the truck at the instant that the accident took place. This was achieved by simulating the overturning truck, placing it in the normal position, with all wheels on the ground, and calculating the offset distance from the curb of the median island of the roundabout.”

From the early days of AutoTURN, accurate and reliable results and engineering controls have always been in place to give road engineers confidence that their designs were safe. If the software helps companies like Vale S/A operate more safely and efficiently, it has done its job.

Johns is with Transoft Solutions.