A successful adaptation

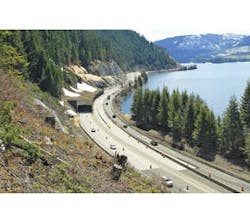

I-90 is the main east-west transportation corridor in the state of Washington, connecting the large population and business centers of the western half of the state with the agricultural industries and recreational areas that comprise the eastern portion.

The uninterrupted movement of people, freight and business over the I-90 Snoqualmie Pass is essential to the economic vitality of the state. However, travel along Snoqualmie Pass is not always reliable due to miles of standstill traffic during busy summer weekends and closures in the winter due to avalanche control work.

In 2005, the Washington State Legislature approved $551 million for the Washington State Department of Transportation (WSDOT) to improve five miles of a 15-mile-long section of I-90 east of Snoqualmie Pass by adding new lanes, replacing deteriorating concrete, extending chain-up and -off areas and replacing a snowshed with two new avalanche bridges. Moreover, this project addressed wildlife connectivity by replacing bridges and culverts with new structures that facilitate the movement of wildlife both under and over I-90.

Phasing it in

The topography, geology, weather and traffic constraints along the I-90 corridor presented unique engineering challenges. The first five miles of the project ran along a narrow corridor between the shores of Keechelus Lake and the steep mountain slopes of the Central Cascades. The Central Cascades produce extreme temperature fluctuations, severe seasonal rains, and heavy snowfall during the winter, which limits the construction window to approximately seven months of the year. In order to work around these challenges, the five-mile project was divided into three major construction contracts—Phase 1A, 1B and 1C. In addition, WSDOT committed to keeping two lanes of traffic open to the public throughout the course of each phase during peak travel times. The only exceptions to the lane openings were during blasting and tie-in work.

Not only were engineers faced with landscape challenges, but I-90 is located in a national forest and the I-90 project area is part of the 212,700-acre Snoqualmie Pass Adaptive Management Area (SPAMA). It is one of ten adaptive management areas in the western United States. When SPAMA was established in 1994, it marked an important change to federal land management in the area. In place of an earlier emphasis on timber production, the goals of SPAMA were to provide mature forests and habitat connection for species moving north and south.

In order to meet requirements of SPAMA, WSDOT created an interdisciplinary team (IDT) made up of the U.S. Forest Service, U.S. Fish and Wildlife, U.S. Department of Ecology, U.S. Army Corps of Engineers and the U.S. Environmental Protection Agency, along with local agencies.

“The IDT developed solutions to ensure the I-90 project complied with SPAMA while still meeting the needs of the traveling public,” said Bill Sauriol, WSDOT environmental manager.

Blasting away

For the past six years, WSDOT and contractor crews have been successfully transforming a 60-year-old stretch of I-90 into a modern, wider, more dependable transportation corridor.

The transformation started in spring 2009 when WSDOT’s contractor, KLB Construction, built a temporary detour bridge at Gold Creek to use during the next phase of construction (Phase 1B). Crews spent the summer excavating over 250,000 cu yd of material from Keechelus Lake.

“Keechelus Lake is one of several irrigation reservoirs in a system where water rights are over-allocated, so WSDOT was careful to not impact lake storage volume levels,” said Brian White, WSDOT assistant regional administrator for construction and development.

To mitigate lake storage volume impacts, WSDOT had a no-net loss commitment with the U.S. Bureau of Reclamation, by which WSDOT would excavate materials from Keechelus Lake to allow for the expansion of I-90. The excavated materials, consisting mostly of gravel and soil, were hauled to the Crystal Spring Sno-Park to be stockpiled and processed into crushed surfacing base course. The material was recycled back into the project and used over the different phases of the project.

Phase 1A was finished in fall 2009, two years ahead of schedule. The following spring, construction started on Phase 1B, comprising the first three miles of the five-mile project. In 2010, the contractor, Max J. Kuney Construction, started building a new six-lane highway, bridges, slope stabilization, and chain-up and –off areas.

“In order to make room for the new lanes, crews had to remove close to 1 million cu yd of material,” said White. “In order to remove that much material, we had to blast it with explosives. Some of the material was directly embanked into the new roadway, while some material was hauled to the Crystal Springs Sno-Park to be processed.”

For three summers, crews closed I-90 every night for about an hour to blast rock and other material from the hillside. By the time the new section of roadway opened to traffic in 2013, crews had used more than 400,000 lb of explosives and stabilized the rock slopes with over 1,500 rock dowels.

A change in design

In 2011, Guy F. Atkinson Construction was awarded the Phase 1C contract, which finished the remaining two miles of the five-mile project. Before construction started in 2012, Atkinson proffered a Cost Reduction Incentive Proposal (CRIP).

“WSDOT encourages contractors to be innovative in planning and performing their work,” said White. “If a contactor identifies a portion of the project where there can be a cost savings and their product is equivalent to our product or better, we both share in the savings, which is then implemented through a change order.”

Atkinson’s CRIP proposed replacing the snowshed WSDOT described in the 2008 Final Environmental Impact Statement (FEIS) with two elevated avalanche bridges. The bridges would separate the highway from the hillside, stabilize loose material and allow avalanches and debris to pass beneath the bridges. A series of engineered avalanche chutes would direct snow, rock and debris away from the bridge piers.

The bridges would be built using standard engineering designs and approved construction practices, reducing risk compared to the techniques and components required for the proposed snowshed. Ultimately, the new bridges would eliminate the long-term cost of operating and maintaining a new snowshed, and along with all of its electrical, mechanical, and fire and life safety systems savings, a cost savings of approximately $650,000 a year was to be realized.

Since Atkinson’s CRIP proposed a design modification different from the selected alternative in the Record of Decision for the I-90 project, the Federal Highway Administration (FHWA) and WSDOT determined a limited-scope Supplemental Environmental Impact Statement (SEIS) was required in order for the new avalanche bridges to be considered.

After additional environmental analysis and public involvement, FHWA and WSDOT approved the limited-scope SEIS in March 2013.

“Atkinson was given the green light to build the new avalanche bridges in place of the proposed snowshed,” said White.

More challenges

As part of the Phase 1C contract, Atkinson was contracted to build a new bridge just east of where the new avalanche bridges were to be built. The purpose of the bridge was to take eastbound traffic over a portion of Keechelus Lake. In 2012, Atkinson’s subcontractor started building a soil nail wall, which would provide access for crews to start building the foundations for the bridge. However, during construction of the soil nail wall, crews experienced excessive grout loss. Multiple drilling and grouting methods were tried, but the voids were too large to construct a stable soil nail wall. WSDOT immediately stopped operations and worked with Atkinson to find a solution.

Atkinson brought in Jacobs Engineering to work with WSDOT to develop a new design that would eliminate the need for the bridge.

“The design team we hired to help with the CRIP was asked to help with the new design since they were knowledgeable of the project requirements and goals,” said Jason Streuli, Atkinson project manager. “This allowed us to help WSDOT redesign the project area quickly and cost effectively without adding more construction seasons to the overall project schedule.”

The new design shifted the roadway closer to the hillside and away from the lake. The slope along the lake would be stabilized with a 30-ft-high retaining wall and the westbound lanes would be elevated to minimize rock cuts. Construction started in summer 2014 and was completed in the fall of the same year.

“Jacobs and Atkinson worked with us closely to develop a solution that was designed and implemented in a timely manner,” said White.

The future of the I-90 corridor

In 2015, contractor crews will break ground on the next two miles of the I-90 project known as Phase 2A. WSDOT is using $108 million in project savings from Phase 1 to widen the highway from four lanes to six, add a new chain-up area, build six new bridges and the first wildlife crossing in the corridor over the highway.

By 2020, seven miles of the 15-mile I-90 corridor project will be complete. As more funding becomes available, WSDOT plans to transform the remaining eight miles of the corridor into a wider, safer and more reliable stretch of I-90. The remaining eight miles will include the continuation of a new six-lane highway, new truck climbing lanes at Easton Hill and will address issues with wildlife and hydrologic connectivity.

“We will continue to work with our partners and communicate with the public to ensure I-90 is a primary statewide and national corridor. We will keep Washington moving by operating efficiently, adding capacity strategically and managing demand,” said White. R&B