Structural fiber choice for thin concrete pavements can have a significant impact on quality

In today’s dwindling budgeting scenario, state DOTs strive for long-lasting pavement rehabilitation alternatives that require less in future maintenance dollars.

Thin concrete overlays are one such economic rehabilitation alternative for moderately distressed concrete and asphalt pavements. The thickness of these types of concrete overlays varies from 3-6 in. When the thickness is less than or equal to 4 in., they are referred to as ultra-thin overlays; otherwise they are known as thin concrete overlays.

Due to the inherent tendency of thin concrete layers to warp and curl because of environmental effects, thin concrete overlays are often constructed with small-sized panels. Also, because of the thickness limitations, thin concrete overlays are mostly constructed without dowel bars spanning the transverse joints; many transportation agencies use the structural fiber to act as “dowel bars.” In addition to contributing to the joint load transfer, structural fibers were found to improve the post-crack performance of concrete by keeping cracks (e.g., longitudinal, corner, and transverse) tight, which helps reduce the severity of panel fatigue cracking. Overall, these fibers increase the long-term performance of overlays.

Structural fibers are currently available in different material compositions, stiffnesses, shapes, and aspect ratios (AR; ratio of length to effective diameter). Among the various types of structural fibers, synthetic fibers have been predominantly used in the last few decades due to their ease of handling, better dispersion characteristics, and non-corrosive properties. In a survey conducted in December 2016 by the University of Minnesota, Duluth (UMD) for a Minnesota DOT funded research project, it was found that 94% of the fiber-reinforced concrete (FRC) overlays in the U.S. were constructed with structural synthetic fibers, and only 6% contained steel fibers (mostly in Illinois). Table 1 presents a statistical summary of the projects reviewed in that survey. Polypropylene fibers were used in almost all the synthetic FRC projects and polyolefin fibers in a couple of others. The difficulties involved in dealing with the heavyweight steel fibers during mixing is likely the reason for the less frequent use of steel fibers as opposed to the synthetic fibers. The projects reviewed in this study (53%) typically used synthetic fibers at dosages near 3 lb/cu yd, but used dosages as high as 6.5 lb/cu yd for polypropylene fibers and 25 lb/cu yd for polyolefin fibers. Few overlay projects had been reported that used steel fibers, but those that did report dosages between 40 lb/cu yd and 80 lb/cu yd with mixed success.

A performance review of many of the existing and past concrete overlays provides ample evidence of the qualitative benefit of using structural fibers; however, it is still difficult to draw a conclusion on the quantitative benefits of fibers. Incidentally, no significant research studies were available to determine the optimum dosage of fibers as a function of fiber type. To this end, a study conducted at UMD investigated the influence of the fiber geometry and dosage on the post-crack performance of fiber-reinforced concrete. The study compared the post-crack performance of several different types of fibers and established correlations between properties of fibers and the residual strength of the fiber-reinforced concrete, which is an indicator of post-crack performance.

Materials and workability

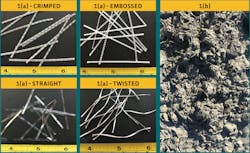

Eleven different types of fibers were included in this study, with varying fiber type, geometry, length, aspect ratio, and manufacturer. Ten of these fibers were synthetic polypropylene, while only one fiber was steel. Of the eleven fibers in this study, four fibers were flat, three were embossed, two were twisted, one fiber was continuously crimped, and one was end crimped (steel). Figure 1 shows examples of some of the fibers used in the study. The fine and coarse aggregates used in this project were collected from a quarry operated by Duluth Ready Mix near Canyon, Minnesota. The coarse aggregate was subrounded grave and the fine aggregate was washed sand. ASTM Type I cement was used in this study.

The addition of structural type fibers to concrete generally decreases its workability (e.g., slump value) depending on fiber dosage, aspect ratio, and geometry. The reduction in slump has both advantages and disadvantages in paving applications. While decreased workability is a problem in achieving the required consolidation, the reduction in workability may increase the cohesiveness of the concrete under a slipform paver, which can help hold the edges of the pavement vertical. It was found that synthetic fibers at dosages greater than 0.75% volume fraction (Vf) occasionally tend to form balls. Figure 2 shows an example of fiber balling observed at higher dosage of synthetic fibers.

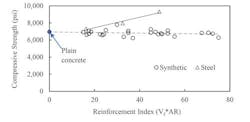

Compressive strength of Fiber Reinforced Concrete

Figure 3 shows trends for both steel and synthetic FRC mixtures tested for compressive strength as a function of reinforcement index. Reinforcement index (RI) is a parameter that combines fiber Vf and aspect ratio (RI = Vf x AR). It can be seen that the change in RI did not significantly influence the compressive strength for synthetic fibers. The average compressive strength for synthetic fiber-reinforced concrete was 6,810 psi, with a standard deviation and coefficient of variation of 323 psi and 4.74%, respectively. The compressive strengths of the plain concrete (6,960 psi) and synthetic FRC were comparable. On the contrary, the one steel FRC tested showed a significant increase in compressive strength and a relatively small increase in modulus of elasticity when the reinforcement index was increased. The compressive strength for the steel FRC increased from 7,330 to 9,320 psi for a change of Vf from 0.25% to 0.75%.

MOR & RS

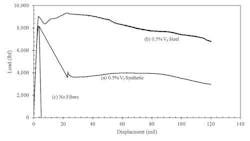

The flexural behavior of the fiber-reinforced concrete was determined by conducting the ASTM C1609 test (standard test method for flexural performance of fiber-reinforced concrete). The dimensions of the beam specimens were 21 in. x 6 in. x 6 in. The length of the span was 18 in. For each mix, five beam specimens were tested. Figure 4 shows a photograph of this test being conducted at UMD. In this test, mid-span deflection and applied force are collected to generate the load vs. displacement curves as shown in Figure 5. Such plots can be used to compute the modulus of rupture (MOR), residual strength (RS), and other flexural performance characterizing parameters. Figure 5 demonstrates the effect of the fibers on post-crack behavior, with fibers offering resistance against crack opening and the ability to carry residual load while the displacement increases. In general, the post-peak load drop for synthetic fibers was greater than for steel fibers.

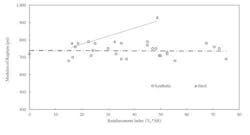

The modulus of rupture vs. reinforcement index is plotted in Figure 6. The MOR is the flexural strength of the concrete measured at the peak load. Similar to the compressive strength, the MOR was also not significantly influenced by the reinforcement index for the synthetic FRCs. The average and standard deviation of the MOR for all the synthetic FRC mixtures was 738 psi and 35 psi, respectively, with a coefficient of variation equal to 4.79%. The MOR for the plain concrete was similar at 720 psi. The MOR for the steel FRC was, however, found to increase with the increase in reinforcement index, especially when the reinforcement index exceeded 32.5.

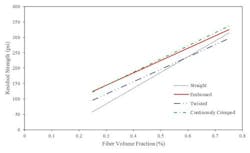

Unlike modulus of rupture, the fiber type and dosage have significant influence on the residual strength (RS). Per ASTM C1609, residual strength is the strength of the concrete at 120-mil displacement. As the residual strength is measured after the peak load, this parameter represents the contribution of the fibers. The higher the residual strength, the higher the post-crack performance or the higher resistance against crack opening. Figure 7 shows that relationship between the fiber volume fraction and residual strength. Data of different fiber types were grouped based on the fiber geometry (straight, embossed, twisted, and continuously crimped). It can be seen that the geometry of the fibers affects the residual strength. In general, embossed, twisted, and crimped fibers have higher RS on average than straight (less lateral stiffness) synthetic fibers, and continuously crimped and embossed fibers had similar and slightly better RS than the twisted fibers, up to a volume fraction of 0.60%. The RS of the straight fibers was consistently lower. Therefore, consideration of fiber geometry and stiffness when choosing fibers for concrete overlays often becomes an economic choice, where the designer must balance cost, workability, and performance. Regarding the influence of the material on the residual strength, steel fibers often outperformed synthetic fibers by a significant margin. Other issues, such as harshness in handling the mix and the potential for corrosion, often dissuade the use of steel fibers in pavement applications.

Conclusions

Structural fiber-reinforced concrete has been shown to enhance the performance of thin concrete pavements, especially when they are exposed to heavy and high volume traffic. Pavement designers have struggled with the best way to choose fiber type and dosage, given the many options available on the market. A method was needed to specify fiber-reinforced mixes for thin concrete pavements that balances economics with performance. Toward that goal, this study investigated the influence of the fiber geometry and dosage on the post-crack performance of fiber-reinforced concrete. It compared the performance of laboratory tested beam specimens containing several different types of fibers in order to establish correlations between the properties of fibers and the residual strength of the fiber-reinforced concrete. Testing of mixes with synthetic structural fibers demonstrated the fact that their inclusion has little effect on compressive strength and modulus of rupture. Steel structural fibers, however, do offer increases in both properties. It was also shown for structural synthetic fibers that the volume fraction of the fiber in the concrete, as well as the stiffness and geometry of the fibers, significantly influence the residual strength. Embossed, twisted, and crimped fibers performed better on average than straight, flat synthetic fibers. By creating fiber volume fraction vs. residual strength curves, designers now have a technique that can be used to better select and dose the best performing and most economical structural fiber to enhance the performance of their thin concrete pavements.