Interstate 10 in northeast Florida is a major east-west artery, connecting the western suburbs of Jacksonville to the downtown area. Along this stretch, it’s bordered by office space, commercial enterprises, and industry. Within the city, I-10 connects with I-95, a major north-south interstate. Together, they are the fourth and fifth longest interstate systems in the U.S.

However, this section of road is not only a densely traveled highway, with additional volume anticipated over the next 20 years. It is also a primary hurricane evacuation route for the northeast portion of the state and was in significant need of additional lanes.

In 2018, the Florida Department of Transportation (FDOT) requested bids for widening about a five mile stretch of I-10 in Duval County. “We submitted our letter of interest in November 2018 and were selected to deliver the project through FDOT’s two-step design-build procurement,” said David W. John, PE, lead roadway engineer for WGI, Inc. “The purpose was not only to increase safety and capacity in the corridor, but to encourage economic growth and revitalization,” he added.

Work began on the project in summer of 2020, and it involves widening this section of I-10 from six to 10 lanes in one area, as well as from 10 to 14 lanes in another area.

Highly Constrained Work Area

John and his colleague, Joshua E. Mattox, PE, who served as the lead roadway engineer on the project, noted that WGI faced significant challenges.

“This corridor lies between local frontage roads a few feet off the right-of-way, with interchanges typically spaced less than a mile apart,” they said. “It was a vertically and horizontally meandering right of way that, on average, provided 200 feet of width to fit 160 feet of pavement, mechanically stabilized earth (MSE) retaining walls, linear ponds, lighting, utilities, and maintenance access.” Those constraints meant that every design element needed to be optimized to a far greater degree than an ordinary design would require.

In addition, this stretch of interstate includes 20 bridges, all of which had already been widened multiple times before. Widening them again required that existing vertical clearances be maintained while the side street amenities were also upgraded.

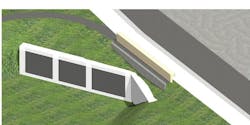

The project also required fill in-place replacement and widening of an existing bridge culvert and a pedestrian tunnel beneath the interstate—all while maintaining lanes carrying 200,000 average daily annual traffic (AADT). This process necessitated temporary drainage measures during the replacement process.

Further, existing retaining walls had been constructed without regard for the prospect of future widening. “These consisted of both perched cantilever walls and perched sheet pile walls with tiebacks, restricting excavation techniques for constructing the proposed MSE walls,” said John and Mattox. “Contractual requirements created the need to remove some of the existing walls to provide adequate strap length. Other locations required tiebacks and wall widening as little as two feet from the existing perched walls.”

A Precise Digital Model

FDOT chose Bentley’s ProjectWise, OpenRoads, LumenRT, OpenBridge Design, and OpenBridge Modeler for the project team, contractor, and subconsultants.

“Accuracy in design was paramount,” said John. “Since this job was a concrete widening project using 3D surfaces and automated grading machinery, the joints needed to be very accurate and within construction tolerances both vertically and horizontally. Otherwise, they wouldn’t be usable.” Other locations that required a highly exacting design were underneath existing bridges and along the right of way.

ProjectWise allowed WGI to efficiently coordinate with other disciplines and subconsultants, explained Mattox and John, while LumenRT generated conceptual renders to help the public visualize the improvements, particularly for the pedestrian plaza. OpenBridge and OpenRoads were used to meet the project’s demanding constraints and prevent potential complications in the field.

Taken together, the information provided by the Bentley applications enabled WGI to visualize every discipline within a single corridor model. For example, the drainage design—and specifically the linear ponds—were able to be balanced between the ever-changing right of way and roadway elevation to achieve permit-required nutrient removal.

Also, the existing concrete slope pavement under bridges was being cut back and replaced with retaining walls to accommodate pedestrian facilities and improved aesthetics, and the digital model enabled better coordination between roadway and structures.

The software applications were particularly helpful in upgrading the retaining walls. “Our digital design enabled our team to provide multiple iterations of proposed solutions in a relatively short period of time,” said Mattox and John.

The Benefits

OpenRoads helped maximize the corridor’s limited space and reduced the installation of the piping network to save an estimated USD 1.3 million. Minimizing the size of the retention walls by 10% saved an additional USD 850,000.

For a project with such tight tolerances and virtually no room for error, precision was essential. “The digital terrain needed to be of the highest accuracy,” noted John. For example, during modeling, WGI discovered the proposed widening of a 10-foot-long section of a side street would have caused a pedestrian drop-off issue that would otherwise have gone unnoticed. The team was able to visualize the problem in the model and remediate it before it got to the construction phase.

The takeaway? Mattox said, “This project emphasized how invaluable it is for all disciplines to be familiar with 3D design and onboard with the modeling process.” By utilizing a collaborative design and construction software solution, WGI has been able to successfully tackle a difficult and complex project.

The I-10 widening project is anticipated to be completed in early 2025.