Recently U.S. Transportation Secretary Sean P. Duffy, told a group of Congressional members and infrastructure stakeholders that, “Our mission is to build as quickly and as much as possible,” in advance of Congress’s surface transportation reauthorization process that will occur in the fall. The Administration’s urgency to accelerate project delivery is promising, however, decades of underinvestment and reactive maintenance have compounded the challenge of refurbishing U.S. Roadways. As reported in the ASCE 2025 Report Card for America’s Infrastructure, 39% of major roads in the U.S. are in poor or mediocre condition, and driving on these deteriorated roadways is costing the average driver $1,400 per year in vehicle maintenance and time lost in congestion. To build resilient roadways, a paradigm shift toward building for long-term performance is needed.

Both the Transportation Research Board (TRB) and the Federal Highway Administration (FHWA) recognize that resilient, long-term pavement requires a durable foundation design. Thus, a stabilized subgrade is critical to the long-term success of any roadway.

Subgrade stabilization is the process of improving the engineering properties of soil to support pavement structures. The goal is to enhance strength, reduce moisture sensitivity, and ensure long-term durability under environmental and traffic-induced stresses.

Chemical Stabilization: Traditional but Temperamental

Weak, moisture-sensitive, or expansive soils can compromise the integrity of roadways. Traditionally, chemical stabilization methods, such as lime or cement treatment, have been used to address these challenges. This method involves altering the soil’s chemical composition using additives. The two most common chemical stabilization treatments are lime and cement.

Lime Stabilization: Lime reacts with clay minerals, reducing plasticity and increasing strength through cation exchange and pozzolanic reactions. However, it requires specific soil chemistry (adequate silica and alumina) and favorable environmental conditions (temperatures above 40°F). Not suitable for soils with high organic content, low clay content, coarse-gradations, or sulfates.

Cement Stabilization: Portland cement provides all necessary chemical components for bonding soil particles, making it less dependent on soil mineralogy. However, it is more expensive and shares similar durability concerns with lime. Not suitable for soils with high organic content, high plasticity clays, sulfates.

Challenges and Limitations

- Durability Concerns: Chemical stabilization is vulnerable to the following: water exposure; freeze-thaw cycles (repeated exposure may lead to premature failure); carbonation (CO2 reacts with calcium compounds within the cement – resulting in a loss of strength); and soil expansion from sulfate attack (sulfates within the soil may react with lime stabilization compounds causing swelling/uplift); and sulfate attack. These factors can degrade the long-term performance of the roadway over time.

- Environmental Sensitivity: The process is highly dependent on temperature, moisture, and soil chemistry. Improper conditions can halt chemical reactions permanently.

- Health and Safety Risks: Lime and soil cement are corrosive, presenting dangers to both workers and adjacent properties. It is vital to implement dust suppression and safety protocols during installation. Chemical stabilization has been shown to leach carcinogenic toxins such as alkaline compounds, crystalline substances, and chromium, which can result in long-lasting detrimental effects on the environment.

- Complex Mix Design: Involves comprehensive laboratory testing (2–3 weeks) to identify the appropriate type and dosage of additive according to soil characteristics. Soil samples collected on-site must be submitted to a laboratory for analysis of chemical compatibility and necessary concentration prior to the start of installation/processing.

- Construction Delays: Curing time ranges from 2 to 14 days, during which the area cannot be trafficked.

While chemical stabilization can be effective, its success hinges on precise conditions and careful execution.

Geosynthetics: A Modern, Mechanical Solution

Geosynthetics offer a mechanical approach to subgrade stabilization. These polymer-based materials, such as MIRAFI geosynthetics, are placed between the subgrade and aggregate layers to reinforce and improve load distribution. This is achieved through the following functions:

- Separation: Preventing intermixing of subgrade and aggregate.

- Filtration and Drainage: Allowing water to pass while retaining soil particles.

- Confinement: Restricting lateral movement of aggregate, enhancing stiffness and load-bearing capacity.

This creates a mechanically stabilized layer that performs consistently regardless of soil type or environmental conditions. Additionally, geosynthetics with wicking yarns can offer both active and/or passive moisture management to the aggregate section for improved long-term performance.

- Active Moisture Management: The continuous process of controlling and removing moisture from soil and aggregate materials. A geotextile with active moisture management decreases volumetric water content within the structural section, eventually increasing the soil resilient modulus, MR. The improved MR results in a more supportive structural section that will sustain higher loads and lasts longer.

- Passive Moisture Management: The wicking yarns equalize the moisture content across a road section minimizing localized, uneven expansion or contraction across a roadway when installed over fine grained soils (reducing expansion and contraction in clays and reducing differential settlement in silty soils). The moisture balance of roadway soils through passive moisture management increases the long-term durability and functionality of the roadway.

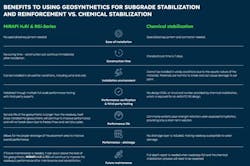

Geosynthetic advantages over chemical stabilization

- Immediate Use: No curing time. Construction can proceed as soon as the geosynthetic is installed.

- All-Weather Installation: Can be deployed in cold, wet, or windy conditions without affecting performance.

- Universal Applicability: Compatible with all soil types, regardless of pH, mineralogy, plasticity, clay content, organic content, or sulfate content.

- No Health Hazards: Inert materials pose no risk to workers or the environment.

- Simplified Construction: Requires no specialized equipment or contractors—standard earthwork crews can handle installation.

- Superior Durability/Lasting Performance: Unaffected by freeze-thaw cycles, water exposure, or chemical degradation.

- Cost Efficiency: Reduces the need for undercutting and aggregate, lowering material and labor costs.

Making the Right Choice

When faced with soft, unstable or problematic subgrade soils, the instinct may be to reach for traditional chemical solutions. However, the long list of environmental, logistical, and durability concerns makes chemical stabilization a less attractive option in many scenarios.

Geosynthetics offer a modern, reliable, and cost-effective alternative. Their ease of installation, adaptability to all soil types, and resistance to environmental degradation make them ideal for today’s fast-paced and sustainability-focused construction projects.

Conclusion

As infrastructure demands grow and construction timelines tighten, the need for efficient and resilient subgrade solutions becomes more critical. Geosynthetic-reinforced mechanical stabilization stands out as a superior alternative to chemical methods, offering long-term performance with fewer risks and complications.