Wet Retroreflective Pavement Markings Can Help Prevent Crashes

Numerous studies show that rainy nighttime conditions pose a considerable danger to motorists.

In fact, 49% of fatal traffic crashes occur at night, even though we only do around 25% of our driving during nighttime hours (1). Adding rain to the mix can increase crashes by as much as 57% (2).

“Wet nighttime conditions present a dangerous, complicated time for driving,” said Adam Pike, Principal Investigator for the Texas A&M Transportation Institute (TTI).

There are a number of factors that make it challenging to drive in wet nighttime conditions. One study suggests that, at night, drivers can only see about 5% of what they see in the daylight (3). A vehicle traveling at 60 mph needs about 200 ft to stop, and standard low-beam headlights only reach 160 to 250 ft in front of a vehicle, making it difficult for drivers to see objects in the road in time to react. Rain further impedes visibility by reducing the clarity of windshields and increasing glare from the headlights of oncoming vehicles. On top of all this, water on the road tends to reduce traction and create slippery conditions.

The biggest challenge for drivers in wet nighttime conditions may be seeing the pavement markings that provide lane guidance and are essential for safe driving. In wet nighttime conditions, standard pavement markings can become nearly invisible. “Most anybody with a driver’s license has driven at night through a rainstorm and has likely lost track of the pavement markings. That’s a pretty unnerving situation to end up in,” said Ethan Peterson, Pavement Marking and Crashworthy Engineer at the Minnesota DOT (MnDOT).

To understand why this happens, let’s explore the science behind what makes pavement markings visible in the first place.

The Science Behind Pavement Markings

Road planners have recognized the importance of clear, consistent lane guidance for a long time. To increase the visibility of pavement markings and improve road safety, engineers in the industry have worked to advance pavement marking technology over the years, from simple painted white lines to the highly visible retroreflective pavement markings we often see on roads today.

Standard retroreflective pavement markings contain spherical glass beads (optics) embedded in a pigmented binder (usually yellow or white) to improve nighttime visibility. Here is how they work:

- Light from a vehicle’s headlights hits the pavement marking.

- The optics bend the light in a predictable, controlled direction.

- The light reflects off the pigment on the backside of the optic.

- The optics bend the reflected light again to return a cone of light to the driver.

The amount of light that is reflected back to the driver depends on a few different factors, including the refractive index (RI) of the optics and the air surrounding the optics. Most standard retroreflective pavement markings contain optics with a 1.5 RI. This is sufficient in normal, dry nighttime conditions. However, water has a higher RI than air. As a result, light hitting a wet pavement marking tends to reflect back in a much broader, weaker cone, meaning that much less light returns from a vehicle’s headlights to the driver’s eyes—significantly reducing the visibility of the pavement marking.

The Safety Benefits of Wet Retroreflective Pavement Markings

As road planners, traffic safety experts, and transportation agencies became increasingly aware that a disproportionate number of crashes occur in rainy nighttime conditions, they sought to understand why. They quickly identified the visibility of pavement markings in these conditions as a primary factor.

Based on this insight, manufacturers, engineers, researchers, and safety experts collaborated to develop pavement markings that deliver high visibility in most conditions—day or night, rain or shine. The latest in pavement marking technology—wet retroreflective pavement markings—are made with ultra high-visibility 2.4 RI retroreflective optics. These high-performance optics reflect a narrower, more concentrated cone of light to counteract the effects of water and deliver brighter retroreflection in wet conditions. When combined with 1.5 RI – 1.9 RI retroreflective optics, this results in high visibility in most conditions.

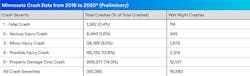

Wet retroreflective pavement markings are an important piece of infrastructure for building safer roads, and studies over the last few years confirm the significant safety benefits of this technology. One study, conducted by the U.S. Federal Highway Administration (FHWA) in 2015, evaluated the before-and-after effects of wet retroreflective pavement markings in Minnesota, North Carolina, and Wisconsin, and found statistically significant crash reductions on freeways and multilane roads (4). The Texas A&M Transportation Institute (TTI) is also very interested in the safety benefits of wet retroreflective technology. In a 2019 study, TTI determined that wet retroreflective pavement markings reduced wet nighttime crashes by 30% and wet nighttime fatalities by 50% in TxDOT’s Atlanta District.

In another TTI study, sponsored by MnDOT and Minnesota Local Road Research Board in 2019, the institute performed a comprehensive literature review, human factors study, and retroreflected light measurements to help establish initial and maintained wet retroreflective pavement marking performance levels.

“The focus of this project was to determine what people need for minimum pavement marking visibility in wet night conditions. This specific objective hadn’t been fully addressed in past research,” said Pike. “We know that wet nighttime driving is less safe for a variety of reasons. On top of that, when pavement markings get wet, they’re typically less visible than in dry conditions. If we can establish minimum maintained wet reflective values, we can enhance the visibility of pavement markings and make them easier for drivers to track. Hopefully, with better lane guidance in these conditions, maintaining lane position will be improved, and abrupt maneuvers and run-off-road crashes reduced.”

In the literature review, TTI found research demonstrating that wet retroreflective pavement markings can reduce fatal and injurious crashes in wet nighttime conditions as much as 60%. Based on their findings in the human factors study, the researchers recommend installing wet retroreflective pavement markings with a minimum initial continuous wet retroreflectivity of 200 mcd/m2/lux (based on a desired four-year service life) and minimum maintained wet retroreflectivity of 50 mcd/m2/lux (5) in situations calling for wet retroreflective pavement markings.

Highly Visible Lane Guidance, When Drivers Need it Most

As we have discussed, driving in the rain at night is challenging. Visibility is low, distractions are high, and road conditions are less than ideal. In these situations, drivers need clear, consistent lane guidance to help them navigate the road.

Pike is hopeful that the FHWA and state transportation agencies can use their research to inform pavement marking standards and specifications going forward. “We found the minimum visibility requirements that people need to see pavement markings in wet nighttime conditions. We also suggested a minimum initial retroreflectivity value. This can help states monitor initial pavement marking installs to make sure they’re getting what they’re paying for with established performance levels. It also provides states with a maintenance metric to consider for replacing pavement markings.”

Peterson believes that highly visible wet retroreflective pavement markings improve driver comfort, which is an added benefit. “With wet retroreflective pavement markings, drivers can see changing roadway circumstances such as curves, intersections, and turn lanes. Then drivers can feel more comfortable about not drifting out of their lane or even off the road.”

Establishing minimum wet retroreflectivity levels for pavement markings can help us build safer roads by providing drivers with highly visible lane guidance in situations when they need it most. This, in turn, can help reduce crashes, save lives, and bring families home safely. “Our goal is to provide pavement marking visibility 365 days a year,” said Peterson. “In Minnesota, that means addressing tough conditions. Ensuring that drivers can see pavement markings in wet conditions is one of the hardest things to do, but we’re striving to get there.”

Visit 3M.com/wetreflective to learn more about wet retroreflective pavement markings and how you can use this technology to help build safer roads. The MnDOT Pavement Markings - Wet Retroreflectivity Standards Study can be found here.

---------------

SOURCES:

(1) Varghese, C., Shankar, U. (May 2007). Passenger Vehicle Occupant Fatalities by Day and Night – A Contrast. US DOT National Highway Traffic Safety Administration. Retrieved from https://crashstats.nhtsa.dot.gov/Api/Public/ViewPublication/810637

(2) Omranian, S., Sharif, H., Dessouky, S., Weissmann, J. (2018). Exploring rainfall impacts on the crash risk on Texas roadways: A crash-based matched-pairs analysis approach. Accident Analysis and Prevention, vol. 117, pp. 10-20.

(3) Conspicuity of Heavy Goods Vehicles. TRV Rheinland Group, Contract Number: SER B27020B-E3-2003-Conspicuity-SO7.28185, 22 December, 2004.

(4) Lyon, C., Persaud, B., Eccles, K. (September 2015). Safety Evaluation of Wet-Reflective Pavement Markings. U.S. Department of Transportation Federal Highway Administration. Retrieved from https://www.fhwa.dot.gov/publications/research/safety/15065/15065.pdf

(5) Pike, A., Johnson, K. (April 2020). Identifying Wet Retroreflectivity Levels for Pavement Markings. Local Road Research Board. Retrieved from http://www.dot.state.mn.us/research/TS/2020/202009TS.pdf