Kansas researchers test temporary rumble strips

In the report titled “Development of Temporary Rumble Strip Specifications,” commissioned by the Kansas Department of Transportation (KDOT), authors Steven D. Schrock, Ph.D., P.E., F.ITE, Vishal Sarikonda and Eric J. Fitzsimmons, Ph.D. add significantly to the body of knowledge of temporary rumble strips (TRS). The authors, Schrock and Sarikonda from the University of Kansas, Fitzsimmons from Kansas State University, provide government agencies and manufacturers with viable specifications and standards, and more importantly, a system by which agencies can classify TRS devices by performance.

To develop these specifications and objectives, the authors:

- Conducted a review of previous studies about TRS;

- Reviewed practices of those state departments of transportation that deploy TRS;

- Tested all commercially available devices on a closed course;

- Collected sound and vibration data for cut-in-place (CIP) rumble strips; and

- Compared that data to sound and vibration data for temporary strips.

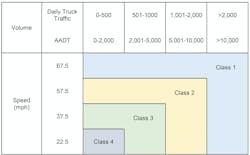

From this data, the authors created a decision matrix, which can be used by government agencies to approve and specify the use of commercially available TRS devices, based on test results and performance class of the TRS.

The authors analyzed the results of closed-course tests, sound tests, and actual work-zone conditions to write class specifications, most of which is summarized in the Decision Matrix (pictured below).

Decision Matrix Parameters:

1. Volume:

Volume is traffic volume, as determined by Annual Average Daily Traffic (AADT) volume, which KDOT provided. Truck traffic is at 20% of the total.

2. Speed:

The matrix shows the various speeds at which TRS devices were tested in closed-course tests. Testing at different speeds was crucial to the development of specifications and class placement. To determine the speeds shown in the matrix, the authors consulted KDOT officials. The resulting speeds reflect real work-zone conditions.

The speeds listed serve as interval limits for each class:

“A test speed of 67.5 mph acts as an upper interval for a class. If a rumble strip tested at 67.5 mph achieves the necessary performance criteria, then the rumble strip can be installed at work zones with speeds equal to or lower than 67.5 mph. Similarly, if a rumble strip is unable to achieve the necessary performance criteria at 67.5 mph, but achieves the necessary performance criteria at 57.5 mph, then the rumble strip is good enough for installing at work zones with speeds of 57.5 mph or lower.”

-Schrock, Sarikonda, Fitzsimmons, Page 18

The Traffic Volume criteria and Speed criteria cover the following conditions:

- Low-speed / low-volume;

- Low-speed / high-volume;

- High-speed / low-volume; and

- High-speed / high-volume.

3. Performance Classes:

The authors established four classes of TRS, 1 through 4, with Class 1 the highest. Again, the classes correspond to interval speeds.

The authors explained the Decision Matrix Class 1 Classification:

“[A] Class 1 temporary rumble strip can be used at work zones whose speed limit is between 57.5 and 67.5 mph, irrespective of the [traffic] volume…. [and]…can be used on roads with volumes of AADT or ADTT exceeding 10,000 and 2,000, respectively, irrespective of the speed of the roadway.”

-Schrock et al, Page 46

Class 1 TRS, then, can be used in all work-zone conditions shown in the Decision Matrix.

The Closed-Course Test:

The authors conducted close-course tests at Heartland Park Racetrack, Topeka, Kan. They used a full-size passenger car for all car tests, and a tandem-axle dump truck for the truck tests. The front axle load was 18,000 lb., the rear 20,000 lb.

Vehicles were driven at the interval speeds of 22.5, 37.5, 57.5 and 67.5 mph.

[The authors tested commercially available portable rumble strips, one of which was PSS RoadQuake 2F Temporary Portable Rumble Strip. RoadQuake 2F Rumble Strip earned a Class 1 rating, the highest of the four classes.]

There are several variables that the Decision Matrix does not contain, but are part of the class placement process. Those variables are: TRS movement, rotation and sound generation. The authors established thresholds for each variable, and for each interval speed. (Please refer to the report for details.)

Classification Table for Class 1 Device:

The authors created four classification tables, one for each speed. (Please refer to the Class 1 Classification Table below; refer to the report for the others.)

From their tests, the authors rated PSS RoadQuake 2F Temporary Portable Rumble Strip a Class 1 device, as linear and rotational movement were all within thresholds for Class 1. No other rumble strip tested met Class 1 specifications.

In this report, the authors delivered a “developed matrix and classification table [that] provides any vendor or DOT staff with a guideline to test the performance of any temporary reusable rumble strips…”.

-Schrock et al, page 52

The authors are aware more study is required in other relevant performance variables, such as vibration generated by TRS at various speeds, but that government agencies can use the Design Matrix now. In addition, they suggested that this matrix could be used to test the effectiveness of other work-zone safety devices.