Pennsylvania Turnpike tests temporary portable rumble strips

To improve both work-zone and worker safety, the Pennsylvania Turnpike Commission tested temporary portable rumble strips (TPRS, or rumble strips) in September and October of 2015.

The goal was to test the effectiveness of TPRS in short-term work zones. Specifically, to determine if TPRS would “…increase driver awareness and alertness upon [drivers] entering the work zone…” The Pennsylvania Turnpike Commission (PTC) considered arrays of rumble strips an “active warning,” as compared to “a passive message warning, such as advanced signage or changeable message signs.”

As such, PTC evaluated TPRS performance in speed reduction, noise levels, changes in driver behavior and movement of the installed rumble strips.

PTC also wanted to determine the effect the presence of law enforcement in a work zone has on driver speed and behavior. A few weeks after the TPRS test, PTC conducted tests with a Pennsylvania State Police Trooper in the work zone.

PTC tested the rumble strip arrays in an active work zone, a mill and overlay project, on Interstate 476, the Northeast Extension, near Quakertown, Penn.

To establish baselines, personnel from Gibson-Thomas Engineering took speed and noise measurements within the active work zone for two nights in September 2015. On both nights, 400 speed samples (a total of 800 baseline samples) were recorded within the transition. Noise measurements were taken on the shoulder’s edge near the location where upstream arrays would be placed.

In addition to collecting speed and noise data, Gibson-Thomas observed driver behavior in advance of the merge. Gibson-Thomas determined at what distance from the lane merge transition drivers decided to merge.

Rumble strip arrays were then installed in the active work zone at Mile Post A-43.1, Southbound, on October 7 and 8, 2015. An array consisted of 3 individual strips, 11 ft long; they are transverse, installed across the lane, and temporary; the strips do not attach to the road, but rather conform to the surface of the road to maintain placement.

One rumble strip array was installed in each lane, left and right, 1,750 ft in advance of the lane closure transition. A third array was placed in the right lane, the lane closure lane itself, 1,250 ft in advance of the transition.

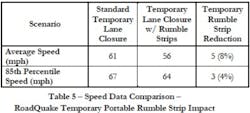

As Table 5 from the report indicates, the rumble strip arrays did reduce driver speed. As the report notes, “…rumble strips are not specifically designed for speed reduction, [but] implementation…does net a modest reduction in both average speed and 85th percentile speed.” (See Table 5 below).

Further, the tests showed, when rumble strips are compared to the PSP trooper:

“The speed reduction caused by the presence of a PSP trooper…has a similar observed speed reduction when compared against the impact of the RoadQuake temporary portable rumble strips on vehicle speeds entering the work zone.”

Regarding noise, the rumble strip arrays had a “negligible impact” on sound levels within the work zone. Though Gibson-Thomas recorded some higher sound levels, those levels were below any that would require countermeasures to mitigate the noise.

To capture driver behavior, Gibson-Thomas measured the distance from the point at which drivers merged into the open lane to the merge transition itself. Rumble strip arrays produced better results than the other two warning systems, the typical work zone signage, and the PSP Trooper.

Once alerted by the rumble strip arrays, drivers merged 650 ft to 700 ft in advance of the merge transition. That is a 400-ft increase over work zone signage, and a 100-ft increase over the PSP Trooper. (See Table 10 below).

The maximum amount of movement observed in the six-hour installations was 13 in. This amount of movement, the report states, is “well within the manufacturer’s movement allowances” of 3 ft for skewing.

PSS defines skewing as when a strip deviates from a straight line, either from the centerline to the shoulder, or vice versa. PSS recommends that users monitor arrays every four hours, as a minimum, and return strips to their original position as needed.

Last, the strips in the test were placed on the road with 10-ft spacing on center. For less movement, PSS recommends that users install strips at 15-ft spacing on center for speeds of 40-55 mph. For speeds above 55 mph, we recommend spacing at 20 ft.

Though the Gibson-Thomas report contains several conclusions and recommendations, we will cite two:

- “Further implementation of the RoadQuake temporary portable rumble strip system or PSP presence entering a work zone should be considered as tools to improve work zone safety.

- Given the comparable results of both the rumble strips and PSP presence, further consideration should be given to the implementation of the RoadQuake system.”

Designed to reduce crashes and save lives, RoadQuake Temporary Portable Rumble Strip alerts drivers to changing road conditions, like upcoming lane closures. PSS welcomes the opportunity to demonstrate the effectiveness of RoadQuake in work zones.

[Note: the rumble strips tested in this project were PSS’s RoadQuake TPRS. Gibson-Thomas Engineering Co., Inc., Camp Hill PA, produced a report for the Pennsylvania Turnpike Commission entitled “RoadQuake Temporary Portable Rumble Strip Pilot Project, Summary of Findings”. The report is dated May 13, 2016, and is the source from which this case study is derived.]

For a copy of the Pennsylvania Turnpike Commission Report, and PSS’s “RoadQuake Best Practices” Guide Book, please contact William Jamieson at 216-658-7552 or [email protected].