Can’t stress enough

We hope you never need a guardrail system, but if you do, you likely will need one badly.

In many states guardrail posts are made from pressure preservative-treated (PPT) timber. For example, the state of Washington has approximately 2 million guardrail posts in service, most of which are PPT wood posts.

A treated guardrail post can last several decades, depending on the treatment efficacy and local climate and soil conditions. Some wood species accept the preservative treatment better than others. For example, Southern Pine has anatomical features that allow preservative chemicals to flow into the sapwood, which is the outermost part of a tree. However, as you move inward to the pith, the darker wood, called heartwood, is not easily penetrated. With western species combinations, such as Hem-Fir and Douglas Fir, even the sapwood is difficult to penetrate, so a method called “incising” is used to improve the penetration. Incising wood is similar to running a flank steak through a meat tenderizer. The small cuts allow better penetration of the preservative chemical into the wood, although the depth of penetration is typically less than 1 in. Seasoning checks and drilled holes for fasteners can create pathways for decay organisms to feast on the untreated wood in the core. So even though the outside of a post appears to be in good condition, the core can be decayed. Clearly, we need a way to look inside of guardrail posts to assess the condition.

A prototype field device to identify internal post conditions.

Nothing too extensive

We surveyed all DOTs in the U.S. and Canada. Respondents included 21 states and three provinces representing the full decay severity zones mapped by the U.S. Department of Agriculture. We found that 84% of DOTs currently allow wood guardrail posts for new installations, so there are both current and future needs for a guardrail post inspection method. Surprisingly, 43% of respondents had no regular guardrail inspection or maintenance schedule outside of construction or collision reports. Only five DOTs used inspection techniques other than visual inspection. These included sounding hammers, probing and occasional corings.

It can be difficult to justify a guardrail inspection program based on cost-benefit ratios. The costs of guardrail testing are easy to tally and include equipment, labor and replacement of deteriorated posts. The key benefits are improving public safety and mitigating liability to DOTs. However, it is difficult to assign a dollar value to a less severe accident. A better way to justify implementation of a guardrail inspection program is as a method to prioritize where limited DOT maintenance dollars can be used most effectively.

Sound sweet spot

Visual inspection is a quick and simple assessment of post condition based on appearance; however, it only allows assessment of the outer shell and gives no clue as to the condition of the core. Probing involves inserting a sharp object into the wood in areas of suspected decay, but this method can only be used to inspect surface conditions.

Drilling and coring are minimally invasive techniques to assess the inner wood condition. Drilling can range from a simple tool from your local hardware store to a more sophisticated device that measures torque as a drill bit moves through the wood. Coring involves removing a core that can be visually inspected and then sent to a laboratory for decay analysis and preservative chemical assays. Both coring and drilling can locate pockets of hidden decay, but these methods are time consuming. Perhaps the best use is in conjunction with another more rapid inspection technique to do initial screening.

Sounding involves impacting the post with a sounding hammer and listening to the resulting sound. This method is popular due to simplicity and low cost, but it is not very reliable and can be affected by factors such as moisture content and surface conditions. Stress wave timing (SWT) is a more sophisticated way to measure stress-wave transit time and calculate resulting wave velocities through a material. Sound wood results in faster velocities, while decayed wood results in slower velocities.

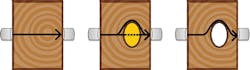

The SWT method is illustrated in Figure 1, showing how decayed wood or voids alter the stress-wave travel path. Note the dashed line on the decayed specimen, indicating a slower wave velocity through the decay pocket. If the decay is severe enough or if a void forms, the stress wave must travel around the defect to reach the stop sensor.

SWT was judged to hit the “sweet spot” of robustness, ease of use with minimal training, low cost, portability, rapid testing potential, and history of successful use for inspection of wood components. Coupled with visual inspection and drilling to confirm readings of decay, SWT can be used to reliably assess the internal conditions of wood posts within a guardrail system.

Metriguard Inc., located in Washington State, was among the first to produce a stress wave timer approximately 36 years ago. This technology has been used for decades to identify wood with interior decay, and some of the earliest research was conducted in Washington State using stress wave timers.

An example of the decayed interior of a guardrail post.

Time with a timer

Washington State University partnered with Metriguard Inc. on this project to develop a wood guardrail post tester—a stress wave timer designed specifically for use on wood guardrail posts, with improved ergonomics, Bluetooth-capable data handling, and GPS recording for use in DOT geographic information systems (GIS). The new SWT also utilized new technology to provide more accurate and precise results while making data recording much simpler than in older stress wave timer systems.

Figure 1. Decayed wood or voids alter the stress-wave travel path.

In addition to improved signal processing, the device uses a solenoid to automatically impact a sample three times and record the corresponding sample stress wave times. The software then calculates the standard deviation between the three results, and if the three samples are not within a pre-defined threshold, the device will repeat the test procedure. If necessary, the prototype will notify the user to re-seat the clamp. There also is potential for this system to interface with cloud storage and current GIS databases. This system was validated with laboratory testing, and field testing was conducted to verify its usefulness. Future versions of the wood guardrail post tester may include optimization for inspections on timber bridges and piles, utility poles and historic buildings.

Positively identified

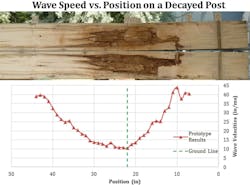

To test the new SWT prototype, 193 wood guardrail posts were obtained from the Washington State Department of Transportation, tested non-destructively with the prototype and then tested with a destructive bending test. After destructive testing, the guardrail posts were ripped, length-wise, in order to determine true internal decay levels. Figure 2 shows an overlay of a decayed post that was ripped and opened for viewing, with the corresponding stress wave velocities. The stress waves were obviously slowed by the internal decay.

The resulting prototype from this research performed well, with an 86% success rate for identifying internal post condition in the lab. The prototype also successfully identified post condition during a follow-up field test. The device can be immediately deployed in the field with either the accompanying computer software or the freely available Android application.

Sound or unsound

To use the device in the field, an inspector first places it on a post at the ground line and takes a reading. The device is then moved to a location just below the spacer block and another reading is taken. Based on the resulting stress-wave speeds at each location, the device assesses whether a post is sound, unsound or somewhere in between.

For sections of guardrail that have multiple unsound posts or posts with questionable readings, occasional drilling is recommended to confirm internal post condition. The drill hole should then be sealed to prevent additional decay. Posts should be marked as necessary for follow-up action or re-inspection after a specified interval.

Further investigation

Wood guardrail posts are subject to decay and deterioration, yet most DOTs have minimal or no inspection procedures in place for them. The objective of this study was to identify nondestructive testing technologies to assess the condition of wood guardrail posts for internal decay. The SWT technique was judged most promising, and a prototype device was developed. The prototype SWT device was validated using wood guardrail posts removed from service. Internal conditions of the posts were accurately detected in 86% of the specimens. The device also successfully detected the internal condition of all posts inspected during a field test. An inspection procedure was recommended for implementation using SWT in conjunction with the drilling of posts that were identified as having suspected decay. Details of the study can be found in the WSDOT research report. R&B