NO. 3 ROAD: Zoo Interchange

The Milwaukee County Zoo is home to over 2,100 living creatures, and sees over 1 million visitors of the human variety on an annual basis.

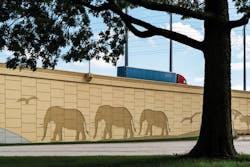

Those seeking to visit the attraction may receive hints as to its whereabouts based on the decorative art etched into the design of the structural walls along the Zoo Interchange, which is flanked by outlined forms of elephants, panthers, rhinoceros, and so on.

The Zoo Interchange is a four-level interchange that serves as the conflation of the I-41 and I-94 crossroads in Milwaukee County, Wisconsin. Originally completed in 1963, it stands as the largest and busiest interchange in the state, accommodating 350,000 vehicles on a daily basis during weekday operations. In recent years, the Wisconsin DOT (WisDOT) had to address the deterioration of structures along the interchange, as they were outdated and could no longer safely handle the required volume of traffic.

“The interchange saw severe degradation—and we actually had an emergency project on one of the structures—so we needed to replace the existing infrastructure as it stands,” Roberto Gutierrez, WisDOT design chief for the Zoo Interchange rebuild, told Roads & Bridges. In addition to the needed structural improvements, WisDOT sought to improve safety and update the design to accommodate the heavier traffic volume along the interchange. The original left- and right-hand entrance ramps had previously contributed to crash rates between two and five times higher than the statewide average. In order to improve safety and freeway operations, the reconstructed system interchange includes right-hand entrances and exits, collector-distributor roadways to remove merging and weaving vehicles from mainline traffic, and additional through lanes.

A COMMUNITY EFFORT

A major component of success on the project for WisDOT was gaining public buy-in, as several key stakeholders depend on the interchange for business. The Wisconsin State Fair Park lies just east of the interchange and exceeds a million annual visitors. On top of that, Miller Park—home of the Milwaukee Brewers—also lies just a few miles east, which attracts thousands of visitors coming through the interchange on game days. And of course, the previously mentioned visitors to the Milwaukee Zoo—which is nestled into the northwest side of the interchange—traverse the area in order to arrive at their destination. What’s more, approximately $50 billion worth of freight runs through the interchange annually.

“These big projects require public trust to be successful because we need cooperation both with law enforcement and working through the small-to-medium details with these folks, and that went a long way toward being successful—keeping everyone thriving during construction,” Ryan Luck, WisDOT construction chief for the interchange, told Roads & Bridges.

WisDOT carried out the project by adopting a reduced impact alternative approach in order to maintain accessibility needs for businesses and neighborhoods. Combined with innovative design methods, the department saved nearly $600 million in the initial estimate for the project just by reducing impact. “We reduced the number of utilities, we reduced the real estate acquisitions we needed, and reduced the risk assessment for contractors,” Gutierrez said.

Since the Zoo Interchange was a major utility corridor, it came with potential schedule and budget overages. To ensure a smooth process, WisDOT produced a first for the state by designing the entire interchange with 3-D surface modeling and clash detection software. “When we leveraged some of the 3-D tools in construction, we were able to build a 4-D model based on the contractor’s steel fabrication sequences,” Luck said. “And in my experience, I hadn’t really ever had a ‘eureka!’ moment by utilizing 4-D tools before, but we had one on this project.”

For the signature flyover ramps along the project, WisDOT implemented a twin steel-tub girder design, which allowed the team to build longer spans with fewer lifts and give them greater flexibility in placing bridge columns. “We had seen the benefit of stainless steel on one of our downtown Milwaukee bridges, and we wanted to leverage the longevity and quality of stainless steel on the highest ramps that would affect multiple ramps beneath it—50 years from now when you might need a redeck,” Luck said. “So we wanted the longest lasting decks on our high-rise ramps.”

Over 30 million lb of structural steel were used on the Zoo Interchange reconstruction, and the team had to work quickly and innovatively on some critical movements for staging purposes that had to be constructed and completed on schedule. “Trying to move these huge steel girder pieces—in some cases underneath these electric lines and maintaining our clearance requirements—was quite a trick,” Pat Cashin, lead structural engineer with HNTB, told Roads & Bridges. “In some cases we ended up building temporary shoring for the sole purpose of access for a crane to get to a point.”

One element of the project included a new five-span through plate girder railroad bridge over I-94 on the project’s west leg. The bridge included 120-ft spans with girders over 12 ft tall and weighing 100 tons. The baseline staging plan included 20 full freeway nighttime closures to erect the girders along with associated cross bracing and decking. To accelerate construction and minimize traffic disruption, WisDOT implemented a 54-hour full freeway closure over a weekend to erect the girders, which led to minimizing nighttime closures from twenty to four, saved a month of schedule, and provided a safer working environment for the contractor.

The Zoo Interchange Core and Adjacent Arterials Reconstruction project rebuilt 7 miles of urban freeway and 4 miles of local roads. All told, the project covered pedestrian, transit, car-pooling, and bicycle facilities, making it the largest multimodal project in Wisconsin history.

WisDOT took pride in finishing this megaproject in part thanks to the community involvement. A plethora of neighboring stakeholders had a voice in the design of the project. “When you’re building these megaprojects and you’re building it within a community, you want to involve the community,” Gutierrez said. The project rebuilt 4 miles of adjacent arterial economic corridors where many of the 90,000 jobs within 2 miles of the interchange are located. The adjacent arterial reconstruction portion of the project improved local neighborhood connectivity, access to jobs, and pedestrian and bicycle accommodations.