The practical application of rural road safety research in Minnesota yields promising results

Applying research. It’s simple, right? How hard can it be? Especially if one believes the ancient Chinese proverb: Tell me and I forget, teach me and I remember, involve me and I learn.

If it is really that simple, why does good research go unapplied? Why do we continue to replicate the same studies over and over? Research can be, and often is, applied with success. But why is some research implemented, while other “good” research ends up sitting on a shelf?

The desire to maintain a high level of customer service (to local governments, roadway engineers, and the ultimate end-users—the drivers) during a period of explosive growth over the past decade in Minnesota’s local roadway safety program drove the need to develop an innovative delivery process. Traditional research uses the approach of identifying a problem to research, doing the research, and writing a report. There is rarely guidance on the next step: implementation.

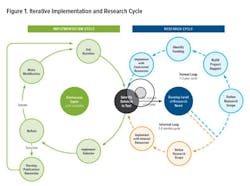

The Minnesota DOT (MnDOT) realized that implementation was the missing piece to applying a successful solution. The following case study provides a better understanding of the Iterative Implementation and Research Cycle and illustrates the integration of communication strategies as part of the process, including knowing your customer and what they need, understanding implementation barriers, and providing clear marketing/outreach tools.

SAFETY IN MINNESOTA

Minnesota is a leader in traffic safety, having successfully reversed—and continuing to reduce—the trend line on annual fatalities. The development of Minnesota’s Toward Zero Deaths (TZD) program—the nation’s first—provided the catalyst for MnDOT to try innovative approaches to make real progress. Under the umbrella of TZD, Minnesota piloted a study that used crash data to develop a data-driven process focused on reducing fatalities. The results of this pilot were a success; MnDOT then needed to roll the program out statewide.

In Minnesota, where almost 50% of fatal crashes occur on local roadways (county highways and municipal streets), MnDOT sought to work with the state’s 87 counties to implement this process statewide. The carrot: sharing HSIP dollars with local governments based on the percentage of fatal crashes. However, with so many miles of roadway involved, an aggressive implementation of low-cost safety solutions was the only option. Based on the pilot’s success, the effort was fast-tracked through the development of a County Road Safety Plan (CRSP) for each county.

TRYING A NEW APPROACH

One way that Minnesota found success in implementing safety research at a local level is through a responsive process approach that focuses on incremental delivery, team collaboration, continual planning, and continual learning. This iterative implementation and research cycle approach, shown in Figure 1, works for quickly implementing safety strategies at a local level.

The following is a small example of how we put this process into practice. Via earlier analytics, MnDOT identified road departure crashes as a high priority. Following the iterative implementation and research cycle, MnDOT staff started an implementation cycle by asking the question: How do we reduce road departure crashes? And then identifying a solution to test. Nationally proven countermeasures were considered first by reviewing the National Cooperative Highway Research Program (NCHRP) 500 series reports. Using these, a short list of strategies was identified for reducing road departure crashes:

- Enhanced edge lines (6 in. rather than 4 in.)

- Shoulder paving

- Curve delineation

- Clearing obstacles for the clear zone

- Shoulder rumble strips

MnDOT began by focusing on a single strategy—the implementation of shoulder rumble strips. Rumble strips were installed on hundreds of miles of local roadways, at locations where local agencies were willing to install a new type of safety strategy. The first rumble strips installed resulted in admittedly mixed reviews. They performed well enough in terms of safety—warning drivers that they were near the edge of the road—but also resulted in a few unexpected issues and one peripheral success.

A hybrid rumble strip design includes a 6-in. pavement marking with 4 in. of painted grooving and an additional 2 in. of grooving outside the painted edge line.

ISSUES ... THEN SUCCESS

The design standards used were focused on state roadways, which generally have wider shoulders and total pavement width as compared to county roads, uncovering a need for new design standards accommodating varying shoulder widths.

Residents along county roadways complained about the noise. While drivers could hear the warning rumble, residents also could hear the noise and viewed it as a nuisance that impacted their quality of life. Bicyclists complained that the edge-line rumbles impacted where they rode on the shoulder and that it was challenging to cross the rumbles. Pavement-marking contractors placed edge lines in the middle of the rumbles rather than near the edge, due to imprecise striping equipment and the perceived need to visually maintain a full lane width.

The placement of the pavement marking on top of the rumbles and within the grooves, however, proved to be very effective on making the edge line stand out more during night and wet conditions.

RESEARCH CYCLE

MnDOT staff decided to address the noise issue first and get to work on researching a new set of questions: Why are some rumbles louder? Why do some have more complaints? During this part of the process, the Research Cycle was engaged (using both the Informal and Formal Research Loops) to try to answer these questions.

Why do some locations have more noise complaints? Through in-field investigation, MnDOT staff determined that the placement of the pavement edge-line marking in relation to the pavement grooving was key. Drivers had a greater likelihood for unintended contact with the edge-line rumble when the pavement markings were painted on top of or in the middle of the rumbles (hit rate of 5%), versus when the edge line was painted to the left of the pavement grooving (hit rate range of 0.5% to 1.0%).

This information was used to develop a new solution, a hybrid rumble design that includes a 6-in. pavement marking with 4 in. of grooving that is painted and an additional 2 in. of grooving outside the painted edge line. This provided drivers with the comfort of driving on or near the edge line (which they tend to do) along with enhanced durability of placing the marking within the rumble.

The results were communicated via email blasts and newsletters to all partners (e.g., state and local agencies, universities, consultants). The information shared included key findings, detailed technical specifications, and inspection and installation best practices. Additionally, MnDOT leveraged opportunities to present the findings during already established meetings (such as conferences and committee meetings) and design forums, and in publications.

Another question, “Why are some rumbles louder than others?” required more in-depth study, which began with a search for different designs or methods of road-edge warnings. MnDOT staff looked at existing national research and best practices by other states and countries. Completed research from NCHRP helped to build an understanding of traditional rumbles and their sound characteristics. Other states and countries had just started testing different approaches that varied in the way the rumbles were cut into the pavement. The most promising was a rumble that was cut into the pavement to represent a sinusoidal curve (Figure 2). The Minnesota Local Road Research Board funded two studies to evaluate specific rumble configurations.

The design standards used for shoulder rumble strips were focused on state roadways, which usually have wider shoulders and total pavement width.

KNOW YOUR CUSTOMER

A common misstep during research is forgetting who is the “ultimate” customer. Often, a researcher will focus on the roadway engineer as the customer, but their bigger role is to implement the results and educate the “ultimate” customer, who in this case was the general public. This education had to occur before implementation could take place and in two phases—first, getting buy-in from the county commissioners, and then from the public. Remembering the customer and what they need (education or information) is often time-consuming and without the proper resources can result in abandonment of implementation.

Regarding outreach, it is advisable to remember the wisdom of the proverb: Involve me and I will learn. MnDOT learned it is important to include all stakeholders and partners throughout implementation. Small simple steps improve chances for successful implementation. An example is to use a technical advisory panel (TAP) to develop the outreach tools. TAPs are typically made up of the stakeholders that use the tools. They provide irreplaceable implementation guidance. Outreach tools should be clear, simple, succinct, and tailored to the audience. Marketing campaigns using more than one communication tool allowed MnDOT staff to tailor these messages to the audience—from on-site consultations/training to handbooks, videos, and fact sheets.

IT'S WORKING!

The iterative approach has resulted in a better rumble strip, with various options to address areas with greater noise concerns.

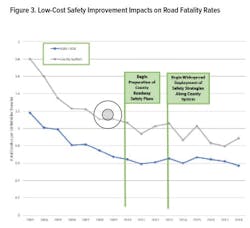

And the numbers do not lie. The development of the CRSPs started in 2010, with the beginning of widespread deployment of targeted safety strategies on county roads in 2012. Since then, 393 projects totaling $86 million of low-cost safety improvements have been installed on the county road network—many of which included rumble strips—and have resulted in a 14% reduction in the fatality rate (Figure 3). Since the inception of the TZD program and initiatives, the annual number of fatalities on Minnesota roads has decreased by 42%, from 655 fatalities in 2003 to 380 in 2018.

To reach this reduction, Minnesota safety stakeholders had to take risks and be willing try new strategies that did not yet have the formal research to prove effectiveness. And then they had to effectively communicate the strategies so the ultimate customer—the public—understood the reasons behind the changes. The risk, it seems, was more than worth it.