The past, present and future of cone penetration testing for MnDOT highway projects

The Minnesota Department of Transportation (MnDOT) Foundations Unit is responsible for providing geotechnical engineering services to a variety of internal clients including the Bridge Office as well as the design, construction, and maintenance groups within eight regional MnDOT districts. While the plurality of work relates to design activities for future road and bridge construction projects, a substantial amount of work is currently related to providing solutions for geotechnical construction issues, failures and other emergencies, often caused by extreme weather conditions.

The cone penetration test (CPT) and variants—piezocone, seismic piezocone resistivity cone, video cone and others—have had successful application in worldwide geotechnical engineering practice for over 75 years.

MnDOT is one of a relatively small number of state DOTs actively using CPT for geotechnical site characterization on program delivery projects of all sizes using primarily in-house resources. Since 2000, MnDOT has performed over 8,000 CPTs in glacial geological conditions. Despite glacial conditions often being considered as difficult ground for this technique, MnDOT uses the CPT on more than 75% of their geotechnical foundation engineering projects. MnDOT is unusual in this regard; despite significant use of the cone penetration test in geotechnical engineering practice worldwide, there is still relatively limited application of CPT data by state DOTs to the design and construction of transportation projects in the U.S. Where it is used, it is frequently by consulting engineers on larger projects, or through alternative delivery project frameworks, rather than as a regular standard of practice, although this is slowly changing.

THE PAST

If you look through the Minnesota Department of Highways (now MnDOT) bridge construction plan archives you will find that hammer soundings were the basis of subsurface characterization until about 1959. These soundings were advanced by driving a metal rod into the ground with repeated blows of a hammer from a consistent drop height. The number of blows per foot was recorded and used as a quantitative measure of penetration resistance.

When the Foundations Unit was created in 1959, new drilling rigs were purchased and rotary soil borings were advanced to obtain both in-situ penetration resistance and to extract samples for lab testing. A different type of in-situ test, the standard penetration test (SPT), came into use; borehole drilling also allowed extraction of soil and rock samples for visual observation and laboratory testing. The geotechnical site investigation process was relatively slow and labor-intensive. Drill crews usually consisted of a team of three individuals: a crew chief, heavy equipment operator (the driller), and a laborer to assist with the tooling and support equipment. During the construction of the interstate system in the 1960s, as many as five drill crews were drilling geotechnical borings for the Minnesota state highway system. Drill rigs from a variety of manufacturers were used; each had different controls and types of hammers for SPT testing. Many early rigs used a roper-and-cathead system to lift and release the hammers. Later, donut and other hammers were replaced with enclosed “safety hammers” which offered improved performance and, as the name implies, reduced risk of crew injury.

Depending on whether hollow-stem augers or drilling fluids were used, set-up, drilling and sampling, and tear-down operations for a borehole could take anywhere from a day to two weeks, for deep holes with problematic soils or rock coring. Typical “bridge criteria” borings, usually between 75 and 150 ft deep, average about a week to advance accounting for travel time, traffic control, weather, maintenance and other factors. Although the SPT test is an in-situ test, there can be a significant amount of additional lab time for moisture content and classification/identification confirmation as well as location and final boring log preparation processing time. Some undisturbed tests on thin-walled samples could take additional time, especially triaxial test series or incremental consolidation. As such, even using several drilling crews and rigs, it would usually take several weeks to advance several borings for even “fast track” projects. While this was an appropriate pace for well-planned projects, it often resulted in delays on construction projects or emergency projects, such as unstable slopes or roadway wash-outs.

Rotary drilling with SPT testing would be the predominant method of site investigation for DOT projects for the next 40 years with few changes from the procedures established in the 1960s. One notable improvement: in the late 1990s automated hammers were calibrated for the first time, greatly improving the consistency of data recovered due to the variability in equipment efficiency. Drilling was still a slow process, and about this time there was a department push to reduce project delivery time from project scoping to project letting. Techniques to accelerate the geotechnical investigation process were of interest; electronic field logging, automated lab testing, and CPT were among those thought to be of the greatest potential value. To test the applicability of CPT testing, MnDOT conducted a set of demonstration projects and purchased a CPT “add on” system to use on a drill rig. At the same time, the purchase of a new track-mounted borehole drilling rig was underway. Due to unforeseen circumstances, final delivery and acceptance of that rig was interrupted. The drilling system was moved onto a truck chassis and the tracked carrier was then available for the manufacture of a dedicated CPT rig. At this same time, the CPT technique was beginning to become somewhat more common in geotechnical practice. Consulting engineers at larger national firms were familiar with CPT soundings. CPT equipment also was changing from analog to digital, and DOS-based computer systems were being replaced with Microsoft Windows operating environments, dramatically improving the user/operator experience.

In November 2000, the next significant change in MnDOT field practice occurred, with the introduction of a dedicated CPT rig. It was immediately deployed on production projects, starting with a large bridge river crossing project. Several deep CPT soundings made the usefulness of the technique strikingly clear on the first day of field operations. Not only was the system comparatively fast, but it also was able to capture much more information during a push showing the complexity and variability of the site’s subsurface character. Sand seams and clay lenses, missed by standard SPT sampling intervals, were shown with clarity on the CPT logs.

In the early days of MnDOT CPT use, soundings were usually advanced alongside soil borings and used in conjunction with the boring information for the development of geotechnical recommendations. An engineer frequently worked with the CPT crew in the field to aid in the technical debugging of the systems and to help develop standards of practice for the new equipment. Due to a lack of design tools and understanding of the new strength values measured by the various sensors, it took a relatively long time for the CPT to be adopted for design where it was used alone. It was however, immediately embraced as a tool to assess variability, stratigraphy and pore water pressure behavior as these qualitative properties were relatively easy to discern from the graphical logs. For the first several years, the CPT was considered as a supplement to the traditional boring log program. In time, it would be able to stand on its own for many project types and be a preferred technique for some work. Even in the early adoption stages of deployment, due to the speed of the technique, the number of CPT soundings advanced annually significantly outpaced borings—even when there was just a single CPT rig in the MnDOT fleet.

As familiarity with the system increased and it was discovered Minnesota geology was mostly favorable for its use, the program grew. A second, 13-ton truck CPT system was delivered in September 2003, and a third 30-ton truck in September 2016. The original tracked CPT was retired and replaced with a new track rig in May of 2012.

Drivers and challenges

There were a number of factors that made adding the CPT into the portfolio of geotechnical services highly attractive to the engineers at MnDOT, even with concerns about the applicability of CPT use in Minnesota’s glacial geology and the difficulties associated with essentially starting up a new program alongside the existing drilling and sampling operations.

Two key external drivers were at work. More transportation projects were being programmed with an influx in special state bonding appropriations, and those projects were planned with compressed delivery timelines. While there was still compelling interest in keeping the gasoline tax low, transportation investment became a political interest. Specialty bonding appropriations were now being considered and passed in the Minnesota legislature, and with new supplemental funding came an interest in seeing the results of how that money was spent. MnDOT now had a compelling interest in delivering projects on accelerated timelines in order to leverage additional investments based on successful projects.

With the shift to reliability-based design and adoption of the AASHTO LRFD bridge design code, reliability and risk also were increasing in importance within the design framework. With the desire to accelerate projects came the desire to simplify plans and provisions where possible. The CPT was a welcome technical innovation in that it was able to provide better quality data faster than previous methods. More soundings could be advanced, providing improved characterization of a site. This proved to be particularly valuable in risk-based decision making. It became easier to justify the need for geotechnical specialty designs and related design and construction work on the basis of 10 CPT soundings rather than a single soil boring.

In addition to these factors, changes in the field crew workforce, retirements, and other staffing changes made the CPT attractive as it required only two crew members: an operator and an assistant to help manage the CPT rods and hole grouting operations.

While there were a number of favorable drivers, there also were challenges and obstacles to be overcome to start a successful program. Even greater than the challenges associated with investment justification and budgeting start-up and operational costs was the need for several active implementation champions and associated management support. The MnDOT geotechnical section has been at the forefront of adopting new technologies for decades, including data management and automated laboratory testing. The CPT program start-up benefited from having a talented member of one of the existing drill crews that was interested in seeing the new technique succeed, as well as an interested engineer with a skill set in instrumentation and testing. This combined with supervisory and management support provided a key, if not crucial, component to a successful launch of the program. Several other drill crew members either were not interested in learning something new, saw CPT as a competing technique or were less skilled with the electronics—which could have made early development and deployment more difficult and challenging.

Procurement of the equipment was more time-consuming than challenging. Effort was required to develop a comprehensive list of needed components and associated technical requirements for the CPT rigs and push-systems. Additionally the hardware and software associated with the CPT system had to be researched and specified for preparation of bid documents. Budgets needed to be developed for the initial purchases as well as maintenance and replacement of disposable items. The cost of the CPT field vehicles was not substantially different from that of other drilling rigs in the fleet, and as such, the cost was not as significant a consideration as other factors.

Additional challenges included learning the limitations of the new technology both in terms of which field conditions were appropriate as well as the technical operations of the equipment in Minnesota’s comparatively wide-ranging weather conditions. There was the need for specialty field training with both the rig operational systems and the electronics related to data acquisition and processing of the CPT measurements. Establishing expertise in operating the field systems as well as creating the office systems and production environment for data processing, file management, log design and plotting took time. There also was effort needed in training the engineering staff in interpreting the CPT plots and using the information for assessment of the site stratigraphy, as a first step. It would be some time before the measurements were commonly used directly in engineering design. Early use of CPT data was through data processing to provide an “equivalent SPT blow count” where traditional design techniques could be employed.

While the geotechnical engineers at MnDOT were actively becoming more familiar with CPT data in the early years of its use, it would take the span of nearly a decade for internal and external customers to embrace the output and usefulness of the measurements. Even today, different engineers have different preferences in using borings or soundings as an investigation tool and different levels of confidence in the associated measurements.

The increase in customer acceptance can be attributed to a number of factors. CPT techniques are now more commonly being taught by both local and national colleges and universities. There is a Federal Highway Administration (FHWA) CPT Users Group, which is actively promoting the use and wider adoption of the technique. In addition, software for interpretation and design using electronic CPT data directly are becoming more common and more user-friendly. MnDOT is currently in the final stages of development of a CPT design manual, which will be freely available from MnDOT’s website when complete. The CPT technique also is now common enough in U.S. practice that it is no longer unusual to see it cited at conferences or in project case histories. Contractors and other agency owners (states, counties, cities and municipal organizations) also are seeing the technique used more regularly by consulting engineers.

Benefits

From the very first project where MnDOT used the dedicated CPT rig to supplement soil borings, project benefits became clear. The most noticeable benefits were from an engineering standpoint in terms of the volume of data and the data density and quality, but there also were several additional benefits including the speed of the investigations and the comparative safety.

The standard CPT advance rate is 20 mm/sec. About 10 measurements are taken every foot, compared to sampling intervals of 2.5, 5, or sometimes 10 ft where rotary drilling and sampling methods are used. This results in a data density of 100x larger for CPT soundings. Combined with the fact that the advance rate could allow as many as 10 independent soundings to be advanced for each boring, the number of discrete samples could be 1,000 times that as obtained from a traditional boring program. In addition, this information is measured, and recorded digitally, in real time, providing immediate and very repeatable results. The electronic data could then be transmitted electronically via cell-modem or web to the office at the end of each push, if so desired. The electronic data can then be imported into several types of software directly. The near-continuous soil profiles provide excellent resolution of sand seams, clay lenses, the variability of sandy soil deposits and the variability of dynamic pore water pressures. Seismic and resistivity CPT testing, as well as the use of pore-water-pressure dissipation tests, also have added new and valuable tools for site in-situ characterization which were not available with rotary drilling, SPT, and traditional soil sampling techniques.

An advantage of the CPT is that it is a direct-push system, somewhat similar to the dynamic soundings taken by MnDOT a half-century earlier. High speed rotary drilling can be a dangerous operation with high-speed rotating parts and drill rods and tooling being regularly lifted, moved, and dropped into place. The rods and components of a CPT system are generally lighter weight and less dynamic. Removal of the rotating machinery alone is a large improvement in safety by reducing the opportunity for loose clothing to become entangled. Although pinch-points are still present the operation of the CPT system is generally slow enough to allow an aware operator to avoid injury. The speed of the system itself also results in safer operations as the CPT rig and crew are on the highway right-of-way or construction sites for less time.

A CPT operation generally consists of an operator and an assistant operating the CPT push rig and a crew pick-up truck, which represents both fewer staff and a reduced fleet size. MnDOT’s traditional rotary-drilling crews usually consist of three crew members and the drill rig, a crew pick-up truck often with a water trailer, and a support truck (also often with a trailer for tracked and large-tire drill rigs). Additional safety is achieved simply by having a smaller crew. There also are additional economies, however, of generally having fewer days on site and using less equipment, which generally leads to less equipment maintenance and time associated with preventative maintenance and commercial driver checks and logging. Shorter project durations also result in direct savings of travel, lodging and other expenses per project.

While the CPT cannot be used everywhere, nor should it be expected to, it is a valuable technique and in many cases has been the primary site characterization technique for geotechnical engineering design of MnDOT transportation assets from cable guardrail end anchors to bridge foundations.

THE PRESENT

Now in 2018, the CPT has been a component of standard site investigation practice for routine geotechnical project delivery at MnDOT for over 15 years. While new tools such as exploration geophysical methods and remote sensing techniques have been added to the investigation toolbox, the CPT is still the predominant site investigation technique—particularly for sites where an initial screening for future borings and lab testing is practical.

MnDOT has transitioned from a fleet of all rotary drilling “SPT” rigs to a mixed fleet of three CME drilling rigs (one tracked, one large tire and one truck), a Geoprobe, and three Vertek CPT rigs on a Marooka track, International 4x4 truck, and Mack 6x6 truck. Each of the rigs is outfitted with CME safety hammers, annually calibrated for SPT testing.

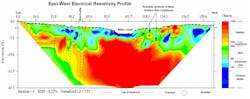

To compliment the traditional boring program, the MnDOT geology section performs several types of Exploration Geophysics techniques (including electrical resistivity and seismic methods) if project site variability can benefit from these techniques. The geotechnical lab uses automated testing equipment to make the best use of the soil and rock samples recovered from the drilling program. Both the SPT and CPT data is processed and stored in Bentley/gINT databases from which electronic logs are generated in PDF file format.

In addition to the in-situ testing at the time of design investigation, CPT, SPT and geophysical methods are further supplemented in some cases with field (time-domain) monitoring where properties are likely to vary with time. Slope stability and groundwater projects usually have a monitoring component, in addition to the initial geotechnical investigation.

CPT plots are now used routinely for mapping stratigraphy and measurements for indirect (c-φ) and direct CPT design. With continued use of the CPT and frequently incorporating it as a component of a larger investigation package with exploration geophysics, and borehole in-situ and lab testing data, customer acceptance of CPT information has improved dramatically, even within the past 5 years.

Representative summary statistics (2000-2015)

While the transportation program at MnDOT varies from year to year, historic trends over a 15-year period have shown a relatively steady number of borings advanced ranging from 100 to 250 annually. During this same period the number of CPT advances ranged from 500 to 1,400. This equates to an average advance footage of about 7,500 ft annually for soil borings and 25,000 ft for CPT soundings.

Expenses and economies

While a fully-outfitted new CPT push rig may be more expensive than a similarly sized rotary drilling rig, the life-cycle cost is substantially less per sounding advance and by most other measures. MnDOT push rig costs have ranged from about $300K to $600K including computer, seismic, grouting and other components.

Lodging, travel and crewmember per diem expenses are essentially identical to SPT crews, per crew member, with the caveat that there is usually one fewer crew member on a CPT rig and often fewer pieces of fleet equipment (usually a support truck and water trailer are not necessary with a CPT site investigation).

Broken, worn, damaged and lost components combined with other disposable items requiring normal and periodic replacement result in costs of about $50K annually for MnDOT operations. This is similar to drill rig preventative maintenance, maintenance, and tooling replacement and upkeep costs. Generally speaking, the reliability of the notebook computers and digital electronics associated with the CPT operating systems has been quite good.

There is a perception of more electronic processing time and effort than with SPT systems (diagnostics, validation, GIS data importing and presentation) although this is simply a function of more data to process associated with more sounding advances. MnDOT uses a two-part process for logging SPT borings where field logs are prepared on paper in the field and then transcribed in the lab into a digital format adding in lab identification, moisture, and testing results. The preparation time for traditional logs is generally longer, but it is performed using a different, less automated, process. Consequently, there are fewer logs to associate GPS data to and subsequently plot. The electronic preparation and filing of soil borings frequently gives the appearance of being easier.

Project benefits

Project scoping is one area where CPT has allowed for a much more robust characterization of alternative alignments than was previously possible with hollow stem borings alone. As the technique is between five and 10 times faster than traditional borings, the density of the number of soundings can increase to add value to preliminary planning and route selection. Improved characterization of alignment alternatives can help improve the understanding of costs and any geotechnically challenging aspects of the work. While relatively rare, some roadway alignments have been shifted to avoid problematic landslides or soft ground areas during the pre-design phase of projects—resulting in cost savings, faster construction and improved long-term performance. Additional value can be added when exploration of geophysical methods are added into the project and the CPT can be more widely spaced to provide “ground-truth” data.

Some benefits, such as the speed and native electronic nature of CPT investigations, are even more striking. In 2007 severe storms in southern Minnesota resulted in flash flooding which, among other damage, completely washed away a single span bridge and all its foundations. The Bridge Office was interested in replacing the structure on MN Highway 74 in Whitewater State Park as soon as possible under an emergency construction contract; the goal was to have replacement plans completed for contracting within one week. This is normally the amount of time associated with obtaining a single boring, not counting lab time. Much of the area was difficult to access due to storm damage and road closures. Access from one side of the bridge to the other involved a considerable detour. The CPT team was able to obtain emergency utility locations and began advancing soundings once a preliminary determination of the new bridge length was made. The crew advanced one sounding on each side of the washed-out structure. That evening from a hotel the operator sent the CPT data and GPS data with the sounding locations electronically to an engineer in the office who processed the information and used it to perform pile length estimates. A report was completed and issued to the Bridge Office the next morning, prior to the CPT crew and truck returning the office.

The CPT also allows in-situ pore water pressure dissipation tests to help characterize the soil type, associated consolidation behavior and static water table. The pore pressure response with time is useful to determine the soil permeability, and it can be correlated with both consolidation and permeability lab tests. The groundwater table can be quickly and effectively determined for granular soils, and although the test takes longer to run, it also is useful for silty and clayey soils. The near-continuous data during pushes also provides insight into the overall stratigraphy and a better representation of seams and lenses of materials. Complex groundwater regimes, such as perched water tables and artesian conditions, also can be revealed using the CPT.

Seismic CPT measurements can be used directly for seismic design work or for determining soil stiffness for use in spread footing project design. Plots can easily be prepared that show the changes in the wave velocity, which can be related to soil stiffness and used to estimate settlement performance. The seismic CPT data has been found to be repeatable and more accurate than correlations to other strength measurements (such as SPT).

Program benefits

While each individual transportation project benefits from the use of the CPT, the overall geotechnical program benefits as well. The relatively fast rate of testing allows for much more rapid investigations than was previously possible. This has allowed for much better characterization of maintenance and construction emergencies. For more routine design projects, benefits range from the ability to meet the demanding timelines to allowing for a greater density of soundings for improved stratigraphic characterization and greatly improved understanding of site variability.

While the CPT can be used with numerous indirect design methods by relating CPT measurements through correlations to traditional Mohr-Coulomb (c-phi) parameters, there are now numerous software packages, especially for driven pile design, that allow CPT data to be imported directly and used for direct design of piling.

The CPT is exceptionally repeatable and provides measurements with accuracy and precision which allows for high confidence in the measurements and calculated parameters. Standardization of the probes, data acquisition systems, and advance rates provides reproducible results that are not nearly as operator and drill rig dependent as the standard penetration test (SPT).

Public (user) benefits

The nature of soil borings is that even shallow ones may take several hours to advance when you include set-up, drilling, sampling, field logging and identification, and tear-down. CPT operations can provide significant project benefits due to the comparative speed and minimally invasive nature of the technique.

While relatively rare, night CPT work can be performed in areas where daytime lane closures are highly undesirable due to congestion, planning/coordination and safety considerations. The CPT technique was used with significant project benefit on a bridge reconstruction project. The Foundations Unit engineers coordinated with district maintenance crews who provided pavement coring support. The pavement cores were removed and the CPT was pushed at several locations to obtain subsurface information for the project. Similar benefits related to safety and lane or shoulder closure times are realized when the CPT is used for investigating cable median barrier anchorages, variable message sign and high mast lighting bases, and other foundations along highways.

THE FUTURE

Looking toward the future to 2020 and beyond, MnDOT will continue to use the CPT as an integral component of its site investigation operations. While in the 1960s rotary drilling and in-situ sampling completely replaced dynamic hammer soundings, the introduction of the CPT in 2000 was never intended to replace drilling completely, but to supplement it and leverage the strengths of both systems. Boreholes would still be necessary for advancing through hard soils, cobbles, boulders and bedrock. While the CPT is quite appropriate for most shallow foundation investigations, Minnesota geology ensures continued rotary drilling and SPT use on many projects, particularly those with deep foundation design needs. In addition, borings are needed for installing instrumentation such as piezometers and inclinometers.

Although it has been discussed for years, “targeted soil sampling and testing” based on preliminary CPT site exploration has been rarely performed. In the majority of exploration cases, borings for projects are advanced using a standard sampling regimen with samples taken at regular predetermined depths (sampling frequency changes based on the depth of the boring, but is otherwise generally consistent). This may result from the borings being scheduled prior to the CPT work, but more generally the incremental cost of performing the standard sampling pattern is relatively low when compared to taking fewer samples once the rig is mobilized to the site. Targeted sampling could minimize the number of samples for lab work and increase productivity, but also may provide a less complete picture of the soil profile—as well as fewer soil samples for tests such as moisture content or Atterberg limits. It is likely that standard sampling will continue to be the default for all but the most specialty projects (such as landslides or poor performance of temporary shoring), where some samples may be clearly more crucial for understanding the site than others and time may be an important factor.

Based on the anticipated volume of work and availability of local geotechnical exploration firms, the MnDOT in-house geotechnical fleet is likely to have a similar composition for the foreseeable future. Both SPT and CPT systems have value and while there may be an inclination toward more CPT systems for safety and speed, there also is a recognition that as drilling is slower and in many cases necessary, that a minimum of two to three drill rigs is a likely long-term fleet composition.

From the original purchase and deployment of MnDOT’s CPT rig, local geotechnical consultants also have embraced the technology and provide services to the state, particularly on design-build and CMGC projects when supplemental geotechnical information is desired or required.

As a new generation of operators is trained and equipment is replaced with newer and more reliable systems—increased CPT use and/or productivity is expected.

Design manual development

Consultants and contractors are more accustomed to CPT; it is now widely used. An identified barrier to wider adoption was the lack of an in-house design guide for applying CPT techniques for various types of project work (e.g., shallow foundation bearing and settlement). In order to promote greater use internally and provide a guidance document for other government agencies, MnDOT undertook a research project to develop a CPT Design Guidance Manual for Transportation Projects. The reference manual is in the final stages of development and consists of background information, step-by-step design practices, preferred relationships and design equations, and worked examples. The manual consists of both tools and design modules, and has been designed to be extensible for the addition of additional tools and modules as development of those added components takes place. It is hoped that the manual provides either a basis or framework from a more nationally oriented practice document, as the content is certainly applicable beyond Minnesota. Part of the explicit intent was that the manual be expandable, freely distributable, and that the content can be used and supplemented by other DOTs, especially if they have additional tools or modules related to local practices.

Increasing value of electronic data

Broad internal and external value is clearly recognized through reduced labor, lower costs, improved safety and faster field operations. Another, perhaps less recognized, benefit is less data manipulation, less duplication of effort, and reduced potential for data corruption, by direct import of CPT data into CAD software or engineering software. The fully electronic nature of the CPT data acquisition system has provided valuable simplicity and convenience in electronic record-keeping and data usage in applications that present the data or use the data for design and engineering calculations. On several recent projects where numerical modeling was used to assess complex foundation designs, the electronic CPT data was invaluable for preparing comprehensive soil models quickly and efficiently. Comparable efforts with discrete SPT data would have provided much less robust models of the subsurface conditions.

In addition to the value of the data for a particular project, the new geotechnical data interchange standard, DIGGS, provides a framework for effectively exchanging data among different organizations. This will likely allow for easier data sharing and warehousing. As with other large data sets, there exists an enormous opportunity to use the data for data mining, mapping, model calibration, and educational or research use.

Design-build and CMGC project delivery method and reliability based design (AASHTO-LRFD) are aiding in structural and geotechnical cross-discipline collaboration to advance new initiatives and improved methods. Geotechnical internal and external customers are using CPT information more routinely and, especially newer engineers, are more accepting of CPT as a site characterization tool for everything from scoping and screening to complex in-situ measurements of seismic, resistivity, and pore water pressure measures in addition to the more traditional values of tip and sleeve stress. In the future the cone penetration test will continue to be a valuable tool in the toolbox—one especially good for establishing greater confidence in design, which will be useful as resistance factors are eventually improved in the LRFD framework.

Reliability and risk

Significantly, the continued use of CPT on MnDOT projects will provide the ability to collect much larger amounts of high-quality data to develop detailed profiles of soil strength and stiffness, and detailed cross sections highlighting thin continuous layers, which ultimately impact design decisions and project cost.

When formerly designing based solely on limited SPT data, the stratigraphic detail (particularly the horizontal variation across a site) was comparatively crude and imprecise. While site investigations, performed now with the addition of CPT techniques, typically cost about the same as SPT-only based investigations, they are faster, provide significantly more data for assessment of variability, and the data quality is higher such that correlations to lab data can be relied upon with greater certainty. Two compelling observations to continue or increase the use of CPT moving forward are that (i) critical investigations and computational modeling designs would have been otherwise impossible to perform without use of the CPT; and (ii) on many occasions the justification for very expensive or time-consuming soil improvement procedures, or use of additional structural systems, was made more compelling by the large amount of high-quality soil strength and stratigraphy inferred from CPT data. This aided in management decisions to spend more time or money on design improvements, design peer review, or construction performance monitoring. In the future, additional high-quality geotechnical information is expected to support a rational decision-making process for both simple and complex geotechnical sites. As project timelines continue to condense, life-cycle costs are considered, risk registries become more common and available transportation funding sources are stressed, the value of CPT testing is becoming more apparent.

FHWA Every Day Counts

FHWA recently announced that Advanced Geotechnical Exploration Methods is one of the 10 initiatives which will be a part of the fifth round of their Every Day Counts (EDC-5) program for 2019 and 2020. FHWA’s Center for Accelerating Innovation works with state, local and private-sector partners to encourage the adoption of proven technologies and innovations aimed at shortening and enhancing project delivery. Along with exploration geophysics and remote-sensing methods, cone penetration testing will be a key component of the program. MnDOT is and active partner in the effort and hopes that other state DOTs will benefit from the EDC program, accelerating deployment of CPT as well as other newer geotechnical technologies.

MnDOT found that older and more conventional subsurface exploration methods (usually associated with rotary drilling) often provided limited and imprecise data for project design, resulting in constructibility issues and increased cost. Moving forward, MnDOT will continue to evaluate new technologies in an effort to more accurately provide geotechnical site characterization. The expectation is that CPT and newer tools, as well as advances in processing and visualization software, will continue to improve design confidence and reduce project risk, and will result in fewer construction problems, shorter project delivery times, and reduced owner and contractor cost.