NEPA approval gets U.S. 219 Link underway in Maryland

A high-profile highway realignment in western Maryland is now under construction following a fast-tracked consulting effort that secured environmental approvals and produced design-build procurement documents within an unprecedented 12-month timeframe.

The project involves the development of a new 1.4-mile highway to realign U.S. 219 between I-68 (the National Freeway) and Old Salisbury Road in Garrett County. The long-awaited improvement will promote safer, easier, and more open access while improving the corridor’s economic viability in the region by providing industrial businesses better access to I-68.

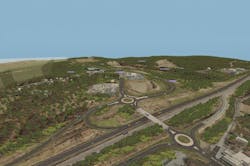

U.S. 219 is part of the Appalachian Development Highway System (ADHS), a network of 32 highways spanning 3,090 miles and 13 states in the eastern U.S. The network was established in 1965 to connect communities to improve commerce and address persistent poverty in the Appalachia region. The current U.S. 219 project includes an existing stretch of two-lane highway that is surrounded by homes and businesses. The new four-lane highway will be constructed east of the current route and will include two roundabouts at the reconstructed I-68 interchange. The direct roadway connection will facilitate development in the area of U.S. 219 while also supporting future regional connectivity by completing the 1.4 miles of eligible ADHS mileage in Maryland.

Dewberry served as lead transportation engineer for concept and preliminary engineering and development of the design-build procurement documents, and supported the development of the National Environmental Policy Act (NEPA) document. The team included joint venture partner Alpha Corp. and team partner McCormick Taylor. The Dewberry/Alpha team was challenged by the Maryland DOT’s State Highway Administration (MDOT SHA) to support community outreach and NEPA approvals, perform preliminary engineering design, develop and assess alternative routes, and prepare design-build documents for procurement within one year—condensing a schedule that typically spans four to five years.

For U.S. 219, the Maryland DOT State Highway Administration partnered with the U.S. Army Corps of Engineers to develop innovative designs that reduce impacts to environmental features.

A MODEL FOR FAST-TRACKED PROJECTS

By facilitating an innovative, integrated approach involving environmental planners and scientists, design engineers, and construction engineers working concurrently, the Dewberry/Alpha joint venture was able to condense the process and support the NEPA planning project with the design-build procurement project simultaneously. The accelerated schedule not only required a high level of collaboration between planning and design, but to accomplish the goal, a number of activities that typically do not run in tandem moved forward concurrently. The result of this collaborative and innovative approach to project delivery allowed the consultant team, working hand-in-hand with its agency partners, to develop design-build advertisement documents and obtain a final Categorical Exclusion NEPA approval within a single year.

Well aware of the pressures to remain on a strict schedule, the team decided to bend the traditional methods by using an integrated project delivery approach to support all project-related activities. With this strategy, multiple planning processes were forced to overlap and occur concurrently when they typically occur linearly. This was a major contributing factor to the team’s ability to streamline the project, and could not have been achieved without an elevated level of trust, the willingness to work outside one’s comfort zone, and constant coordination among such an integrated team. Since there was no time for miscommunications, bi-weekly core team, monthly partnering, and as-needed discipline meetings took place in order to reach timely solutions to any unexpected issues. The team’s ability to communicate and cooperate between disciplines allowed changes to be accommodated before any alterations to the schedule had to be made. Likewise, continued refinements resulting from the acceleration of project design activities created the need to develop multiple iterations of environmental documents before each was finalized.

U.S. 219 stands apart from the typical planning project for its detailed design early in the planning process. The team took old alternatives from a previous study and, through the use of practical design and a value engineering study, developed three comprehensive alternatives that both met the purpose and need of the project and were “right sized” by filtering out the wants from the needs to fit within the available ADHS federal funding. With such rapidly changing design ideas, a high level of coordination was required between planners and designers. By opting for a design-build method as opposed to a typical design-bid-build process, the team was able to further expedite the delivery of the project, while allowing the design-builder more flexibility to bring innovation to the final design. Impacts to the surrounding area are key components to consider when trying to evaluate which alignment to choose; however, by performing constructability reviews, the team was able to reduce the project footprint to avoid and further minimize impacts.

On-site environmental mitigation for the U.S. 219 project included the stipulation for the design-builder to obtain the associated permits with connectivity to the overall transportation project. This was a first for an MDOT SHA design-build project. MDOT SHA has never used innovative delivery methods for environmental-based projects due to the requirement of having final design-level documents to obtain a U.S. Army Corps of Engineers (USACE) permit. For U.S. 219, however, MDOT SHA partnered with USACE to develop innovative designs that reduce impacts to environmental features and provide USACE with a level of comfort in knowing that the designs are constructible, permissible, and could be accomplished during the delivery phase of the project. This new approach to reaching an agreement on the avoidance, minimization efforts, and the initial permit requirements, allowed the team to establish the permitting boundaries versus a specific approach. Furthermore, it allows MDOT SHA more flexibility in providing permitting options, which will allow more innovation on future projects.

A HIGH-PROFILE PROJECT

Public outreach was a critical component of the U.S. 219 project. The team worked closely with local business owners to ensure the project would not “bypass” them. The preferred alternative provided access to the local businesses, promoting continued economic development in the area. Because the existing two-lane highway has more than 40 driveways and commercial entrances, creating extensive conflict points along the route, the new alignment will take the burden of the majority of truck traffic, ultimately reducing traffic on existing U.S. 219 and enhancing safety along the corridor. The project included the development of a 3-D augmented reality environment created by RDV Systems. The interactive 3-D model was used to support the NEPA process and assess design alternatives, with an unlimited number of images and fly-through videos depicting every aspect of the project.

The groundbreaking environmental permitting approach and streamlined process, which can serve as a model for future MDOT SHA fast-tracked projects, was awarded the 2017 Maryland Quality Initiative Planning Award of Excellence.

Construction is scheduled to be completed in 2021. “This important project is another step in the full development of the Appalachian Development Highway System and a great example of all government levels working together,” said MDOT SHA Administrator Greg Slater at the time of the groundbreaking. “This project has been a high priority for travelers for decades, and will benefit travel and commerce in the entire region.”

---------

All photos: MDOT SHA