Digital Delivery Tackles Congestion

By Michael Arens, Contributing Author

State Route 172 (SR-172/5600 West) is a major route in Utah’s Salt Lake Valley. It connects 6200 South and West Valley City to State Route 201 (SR-201) and Interstate 80 (I-80).

This corridor sees average daily traffic of more than 15,000 vehicles, 27% of which are large trucks serving this major shipping area.

While the corridor was bustling, keeping people and goods moving became a problem. An at-grade crossing with the Union Pacific Railroad (UPRR) created hours of delay and caused traffic to back up on the two-lane route. Not only were commuters impacted, but the emissions from vehicles also were adversely affecting air quality.

Partnering with the Utah Department of Transportation (UDOT), Michael Baker International led design and engineering services to address these challenges. The project included widening 5600 West from two to five lanes for the 3-mile section. The project also called for a grade-separated crossing over the UPRR and a shared use path along the new corridor.

The design team realigned 700 South, extended a culvert for the Lee Drain canal, and revised ramps at the I-80 interchange.

The existing I-80 diamond interchange was converted to a diverging diamond interchange, which eliminated conflict points for motorists.

The team’s full design work included alignment and intersection options, roadway, structural, drainage, traffic signals, public involvement, geotechnical design, and post-design support during construction.

The SR-172 (5600 West) Railroad Crossing Project is notably the largest project to date in Utah utilizing a design-bid-build (DBB) digital delivery (DD) format.

By using this format over traditional plans, the team ensured that all project elements were contained within a digital model with attached attributes and references.

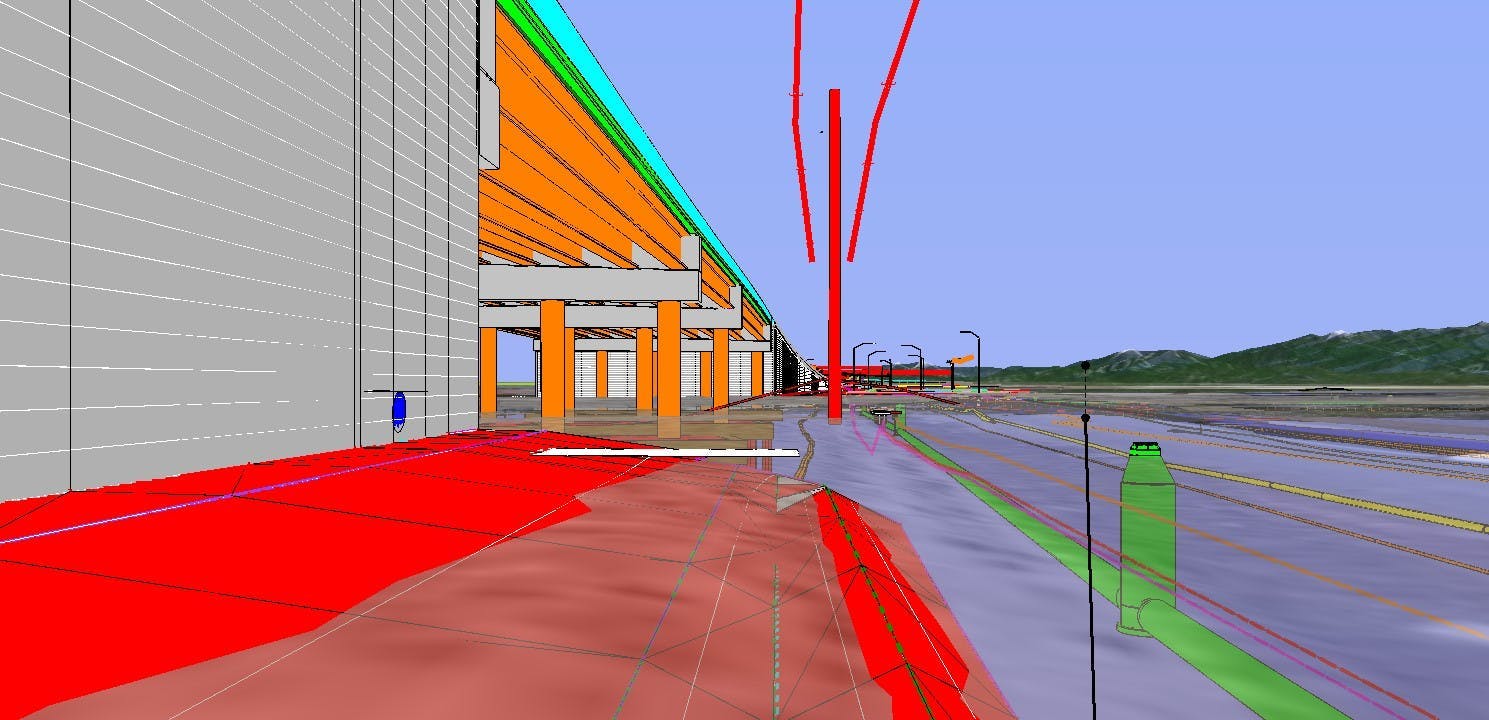

Within the 3D model, designers accounted for all disciplines – including drainage elements, roadway elements, utilities, and more – in one place. The team also included traditional details and data while also attaching photos, videos, and hyperlinks to the model.

These fully 3D designs:

- Illustrated to stakeholders and impacted business owners how the road and structure would be aligned over the railroad, and how the contractor would maintain access during and after construction.

- Could be verified quickly by the contractor in their models, eliminating ambiguity.

- Allowed for collaboration between designer and contractor. For example, the contractor compared their survey to the design to reconcile and compare quantities live, instead of drawing them on 2D sheets, which would then need to be sent back and forth throughout the construction phase.

- Provided the design team an opportunity to understand and improve on the capability of the design accuracy with quantities and bring these issues to the attention of the software developers.

The team developed fully enclosed 3D break lines and surfaces that could be instantly incorporated and verified in the contractor’s model.

This enabled the contractor, Wadsworth Brothers Construction, to understand and break up large dollar bid items by their construction phasing. This reduced the contractor’s risk and UDOT’s price during the contractor bidding process.

The use of this software also provided a streamlined process to manage asset information throughout project development and beyond as it serves as a single source of truth document. Moving forward, UDOT will be able to instantly reference the 3D model electronically.

A goal of UDOT for the future is to have a digital twin recreation of all the assets that exist in the field.

By utilizing a 3D model in the original design and construction of the project, UDOT will not have to perform new surveys and model creation in the future.

The assigned metadata within these models has been verified throughout the construction process. This saves time and money when upgrades and maintenance are needed.

Obstacles

The project team faced challenges throughout design, including coordinating with UPRR on the new structure over the existing rail tracks.

These efforts began as far back as 2018, and regular meetings and correspondence continued throughout the project. The team developed a betterment agreement with UPRR to modify the single-span bridge to a three-span bridge. This allowed for potential future railroad expansion.

By planning and coordinating through all phases of design, the team made sure businesses could function during construction.

The firm’s public involvement team members reached out to all the stakeholders during the design and construction phases. The team worked with each business to identify freight movement needs.

This information was used to make property improvements. Because the team utilized 3D modeling, they could also easily illustrate what the project would look like to those who would potentially be impacted throughout construction through various exhibits.

Maintaining traffic on SR-172 was an important goal for the entire team and effort was placed on keeping traffic moving on both SR-172 as well as the I-80 and SR-201 interchanges.

Additionally, maintaining access to businesses was key to assure a successful project with all stakeholders.

The large amount of truck traffic that serves multiple warehouses in this area of Salt Lake City was maintained by the innovative geometric alignment modification.

This kept the at-grade UPRR crossing open, streamlined construction phasing, and allowed for continuous utility coordination.

The team was able to avoid power pole and sewer lines relocations which reduced cost and met schedule. The team also met all UPRR standards, continued extensive coordination with UPRR, and had no UPRR delays.

Realizing the Benefits

The new corridor over the UPRR tracks maintains traffic along the thoroughfare, reduces safety concerns, and lowers pollution from vehicle emissions.

The elimination of wait time for vehicles enables truck traffic using this route to keep moving.

The SR-172 (5600 West) Railroad Crossing project successfully addressed UDOT’s goals of creating a safer corridor with increased capacity and improved traffic flow.

The corridor’s completion provides economic benefits to the area and a new shared use path was included in the project.

This path provides an alternative to vehicle use and offers a safer opportunity for traffic by separating these users from the heavy vehicles that frequent this route.

There are also plans for future growth in the vicinity of this project, particularly within the Utah Inland Port. Corridor improvement projects like SR-172 benefit everyone in the end. RB