Enhancing deicer performance

For winter maintenance agencies, snow and ice control is a vital function of their work to provide safe road conditions to the traveling public.

Effective and efficient snow-and-ice-control operations can result in significant economic, environmental and social benefits, so agencies strive to use innovative products, technologies and strategies that facilitate the process, reduce costs and mitigate potential impacts.

Currently, the U.S. spends more than $2 billion every year on snow-and-ice control, and applies more than 20 million tons of various salts to the nation’s roadways. For many departments of transportation in severe-weather states, winter maintenance represents a huge portion of their annual budgets.

Traditionally, road agencies have used products such as sodium chloride (NaCl), magnesium chloride, (MgCl2), calcium chloride (CaCl2), or even calcium magnesium acetate (CMA) and potassium acetate (KAc) for snow-and-ice-control operations. However, some of these products may decrease the longevity of the highway infrastructure and adversely impact the surrounding environment.

Agriculturally derived products, or agro-based products, are increasingly popular in snow-and-ice control operations. Agro-based products are either used alone or more commonly as additives that are blended with traditional chloride-based products such as rock salt and salt brine. Agro-based products have been found to reduce the freezing point of water, improve ice-melting capacity and reduce corrosivity when blended with other winter maintenance products. More recently, manufacturers and practitioners have suggested anecdotally that agro-based products help to weaken the bond between ice and the road surface, prolong performance of deicers on the road surface, and better utilize sunlight to reduce ice formation because they often are dark in color. If verified, these performance characteristics could help agencies refine their winter maintenance operations by optimizing material use, timing of applications and reapplication rates.

In partnership with the Clear Roads research program and the Minnesota Department of Transportation, the Western Transportation Institute conducted a laboratory investigation of three agro-based deicers. This research investigated the effectiveness and functional mechanisms of these deicers in their ability to (a) weaken the ice bond to pavement; (b) improve the product longevity on the road; and (c) utilize sunlight more effectively than traditional products.

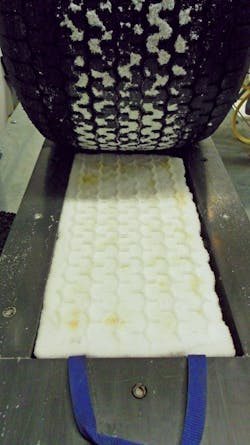

Figure 1. Pavement sample going through simulated trafficking using a custom-built trafficking machine.

Methods

Three agro-based deicers, each with a different chloride concentration, were used for testing. For control purposes, team members conducted a comparison set of tests with no deicer, and with a salt brine solution.

The first set of lab tests investigated whether agro-based products weaken the bond between ice and pavement. The researchers used the products as liquid anti-icers, applying them to non-permeable asphalt pavement samples. They then added 800 grams of snow to the pavement sample, and compacted it to approximately 0.5 in. thick. To simulate vehicle traffic, the pavement samples were trafficked for 500 passes, equivalent to 500 passes of a single tire on the pavement sample. Figure 1 shows the pavement sample undergoing the automated trafficking during testing.

To investigate the impact of the products on the bond that forms between ice and pavement, the research team measured the shear force required to plow the snow from the pavement surface. Snow segments were pulled horizontally using a hollow aluminum box, and the shear force was measured with a spring scale (Figure 2).

To measure the product longevity on the road surface, pavement samples had anti-icers applied to them and were then covered with snow. The snow was compacted, trafficked and plowed using similar methods as in the bonding tests. However, these procedures were followed by steps to add, compact and traffic more snow, and then to simulate traffic in cycles of 250 passes, 500 passes and 750 passes. The bond strength and friction coefficient were measured after each cycle. Additionally, snow samples were collected after each cycle to measure the amount of liquid agro-based product removed with each cycle of compacting, trafficking and plowing.

In order to investigate whether these products better utilize sunlight to reduce ice formation, researchers used a Solar Constant 4000 solar simulation system to provide sunlight. Strategic Highway Research Program (SHRP) ice melting tests were conducted at two temperatures for each agro-based product and a control product. The agro-products were applied to an ice surface, and placed in the cold room and exposed to low, middle and high ranges of sunlight. The ice melting volume for the low, middle and high exposures was then averaged for each deicer type.

Figure 2. Measurement of shear force: Snow cut to 2 x 2 in. segment and hollow aluminum box used to plow the snow with a spring scale to measure horizontal shear force.

Results

The agro-based products showed promising results across all of the lab tests. In the tests measuring the ice bond to the pavement, the products reduced the bond strength between snow and ice and the pavement compared to salt brine alone at two different temperatures (15°F and 5°F), meaning that it was easier to plow the material off the pavement.

The viscosity, or thickness, of the agro-based products also was higher than that of the salt brine in these tests. The viscosity may in part explain the improved results for reducing bond strength, since more viscous products remain on the pavement surface instead of being wicked up into the snow pack.

Bond strength also was an important factor in evaluating product longevity on the road surface. For all three agro products and salt brine, the tests showed an increase in bond strength between the snow and the pavement as the number of trafficking passes increased, regardless of temperature. This result suggests there was a reduction in the amount of deicer remaining on the pavement after each trafficking cycle, with the bulk of the applied deicer lost from the pavement surface after the initial trafficking of 250 passes. Such that as the snow is trafficking more over time, more of the deicer is lost from the pavement surface. The chloride concentration measurements produced similar and consistent results, showing higher amounts of chloride deicers in the snow that was plowed off. The agro products demonstrated greater longevity than the salt brine; however, longevity decreased for all products when the temperature was reduced from 15°F to 5°F.

In the tests to measure sunlight absorbance, all products (including salt brine) showed extremely elevated ice-melting rates when exposed to sunlight. The products that produced the greatest ice melt were the dark-colored agro-based products. The research team speculated that darker-colored deicers may have a significant advantage compared to light-colored deicers because they will absorb more heat from the sun.

Application to practice

Overall, agro-based products have shown improved performance compared to salt brine alone, which is consistent with previous research and anecdotal input from practitioners. The findings that are particularly applicable to winter maintenance practices include:

- The amount of force required to plow the snow off the pavement was significantly reduced by agro-based products when used as anti-icers, compared to that of salt brine alone. Using these products could facilitate and expedite snow-removal practices for winter maintenance agencies;

- Agro-based products appear to remain on the road surface longer than salt brine. These products demonstrated higher viscosity, which may lead to a longer residual effect on the pavement. These properties could help agencies decrease the frequency of deicer applications; and

- Darker-colored agro-based products tend to produce more ice melt when compared to salt brine alone, which means agencies could potentially decrease the amount of product applied.

More research is needed to validate and refine the understanding of how agro-based products perform. For example, the research team recommends further study into why darker-colored products have greater ice-melting capabilities. However, this study suggests that the use of agro-based products may prove to be a cost-effective addition to snow-and-ice-control strategies for many agencies. Winter maintenance agencies will always be on the lookout for products that work faster and last longer so that personnel can do their jobs more efficiently and help keep the roads safe and clear for travelers.

The full report is available at: http://clearroads.org/project/13-02/.

-------------

Muthumani was a research engineer at the Western Transportation Institute at Montana State University. Fay is a research scientist at the Western Transportation Institute at Montana State University. Shi is an associate professor in the department of civil and environmental engineering at Washington State University. Little is a research writer at the Western Transportation Institute at Montana State University.