Resilient Infrastructure

By Kristin Dispenza, Contributing Author

Concrete has earned a reputation as a durable material for building roads. It saves departments of transportation and other road owners money by providing decades of service with minimal maintenance costs. Concrete’s durability has proven to be important for two other critical reasons: sustainability in the face of a changing climate and resilience as frequent and extreme weather events occur.

Sustainability conversations have become part of every construction, maintenance, rehabilitation and expansion project. Incorporating resiliency into those conversations has been a more recent development. But with a changing climate, resiliency should be factored into every sustainability calculation, as well. Resilient infrastructure supports the ability to anticipate, prepare for, and adapt to changing conditions and withstand, respond to, and recover rapidly after a disruptive event. Concrete pavements have proven to be resilient with minimal impact on performance when faced with disruptive events like flooding and inundation.

The Expanding Definition of Sustainability

The United Nations, in establishing the Brundtland Commission in 1983 to unite countries in pursuit of sustainable development, arrived at a definition of sustainability that is still the most accepted definition today: meeting our own needs without compromising the ability of future generations to meet needs of their own. A similar definition, more related to infrastructure, defines sustainability as the capacity to maintain a process or state of being into perpetuity, without exhausting the resources upon which it depends nor degrading the environment in which it operates.

In recent years, it has been suggested that for human activity to meet present needs without compromising the prospects of future generations, we need to carefully balance economic, environmental, and societal demands. This concept is often referred to as the “three pillars of sustainability” or the “triple-bottom-line,” and sustainable solutions are those that address all three elements.

When it comes to designing pavements, this entails designing with a life-cycle approach that considers the pavement’s entire life span. Doing so confers benefits in terms of sustainability and resilience.

Sustainability in Manufacturing

Achieving sustainability begins with addressing the embodied environmental impact of concrete and its mix ingredients.

“Concrete’s ingredients—especially portland cement—have until recently been the primary concern surrounding the sustainability of concrete. Strides taken within the industry to optimize mixtures, however, have resulted in concrete with greatly reduced embodied carbon and there is now a clearly defined path for achieving carbon neutral concrete in the future,” said Eric Ferrebee, Technical Services Engineer, American Concrete Pavement Association.

The Roadmap to Carbon Neutrality, spearheaded by the Portland Cement Association (PCA), outlines the necessary steps and has aligned America’s cement manufacturers in the goal of reaching carbon neutrality throughout the cement-concrete-construction value chain by 2050. Successes to date include replacing ordinary portland cement with portland-limestone cement and the utilization of supplementary cementitious materials (SCMs). Performance-engineered concrete mixtures take the process a step further by not only optimizing the use of SCMs and portland-limestone cement content in the mix, but optimizing aggregate gradation and sourcing, as well.

Life Cycle Thinking

While the Roadmap focuses on concrete’s value chain, it also discusses the importance of life cycle thinking. A pavement’s life cycle begins with design, materials production, and construction, which make up the cradle-to-gate portion of the cycle. Consideration is then extended to the ongoing activities of pavement use, maintenance, and preservation, as well as the end of the pavement’s life, resulting in a more complete evaluation of the pavement’s sustainability from cradle to grave.

Assessment of each phase should go beyond the traditional evaluation of economic impacts to also include the environmental and social impacts. When properly done, designing for sustainability from a life cycle perspective allows designers to evaluate options and the impacts over the full life and from all phases to ensure that short-term gains do not come at the expense of long-term deficits.

Life cycle cost analysis (LCCA) and life cycle assessment (LCA) are essential to assessing sustainability. These tools, in conjunction with pavement design and analysis tools such as AASHTOWare’s Pavement ME (Pavement ME), can be used together to evaluate and improve designs and their associated maintenance strategies to improve all aspects of sustainability.

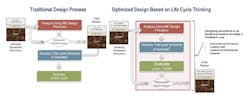

As illustrated Figure 1, the greatest sustainability improvements will be made when this process iterates the pavement design and maintenance cycle development with feedback from life cycle tools.

Figure 1: Design process to incorporate life cycle thinking, adapted from MIT CSHub.

Concrete Offers Use-Phase Sustainability Gains

One of the greatest benefits in choosing concrete over other paving materials is the long life span it can achieve. Concrete can last 30 years or more before requiring a maintenance cycle and this results in a clear improvement over other pavement types when it comes to economic sustainability, even when considering the fact that concrete pavements can have higher initial costs. But concrete contributes to social and environmental sustainability goals, as well.

“Because of the different way that concrete pavement, as opposed to other pavement types, interacts with tires, vehicle fuel efficiency is actually improved by driving on concrete. This is very significant for environmental sustainability,” said Ferrebee.

Pavement-vehicle interaction (PVI) is an area of research that examines how a road’s structural and surface conditions inhibit a tire’s motion—an inhibition that is often called rolling resistance. It takes energy for a vehicle to overcome rolling resistance, which leads to excess fuel consumption and excess greenhouse gas emissions. Researchers at the MIT Concrete Sustainability Hub have identified three main factors that can influence rolling resistance: roughness, texture and deflection.

The researchers conclude that the best performing pavements are ones that are smooth and stiff. Concrete pavements are stiffer than other pavements, and remain smooth longer, significantly reducing the PVI-related environmental impacts of driving on a roadway. Reducing fuel waste and lessening fuel consumption also provide economic and societal benefits for drivers, in addition to the environmental benefits.

High albedo is another environmental benefit of concrete pavement. Albedo is the measure of the fraction of solar energy reflected by a surface. Lighter color surfaces reflect light and have a high albedo (maximum = 1), while dark surfaces absorb light and have a low albedo (minimum = 0).

Choosing pavements with high albedo helps mitigate climate change and global warming potential by two major mechanisms: radiative forcing (RF) and urban heat island (UHI).

RF measures the Earth’s energy balance. It is the difference between the amount of energy that enters the Earth’s atmosphere and the amount of energy that radiates out into space. Increasing albedo radiates more energy out from the Earth and has a cooling effect. Because the Earth has an albedo that’s approximately between 0.3 to 0.35, building a pavement that has a different albedo will impact the radiative forcing and change the amount of solar radiation that is reflected into space.

This is where concrete has a large advantage in sustainability. A concrete pavement’s albedo starts out light (about 0.40 for new pavement) and darkens over time (0.2 for old pavements). Asphalt pavements start out dark (0.05 for new) and lighten over to time (0.15 for old). In addition, when the pavements are rehabilitated, either through diamond grinding for concrete or asphalt overlays for asphalt, the pavements go back to their original albedo.

Increasing albedo also decreases the ambient air temperature attributable to Urban Heat Islands (UHI). Urban heat islands are areas with buildings and infrastructure that retain solar energy and generate higher temperatures compared to natural landscapes.

A recent study from MIT’s Concrete Sustainability Hub (CSHub) found that concrete’s high albedo can help reduce the UHI impact and reduce the temperature of a city like Phoenix by up to 2.1 degrees celsius. When assessing a pavement’s net effect, however, calculations based on location, climate, urban geometry, building properties, energy grid and more should be performed for individual urban areas, since research has shown that the incident radiation reflected from pavements can, in some cases, have a warming impact on surrounding buildings, increasing their cooling and heating needs.

A phenomenon receiving increasing attention is concrete’s ability to absorb CO2 from the atmosphere. This absorption, known as carbonation or carbon uptake, occurs as a pavement ages. Researchers at MIT’s CSHub describe the carbonation process as one in which “CO2 from the air reacts with water in concrete pores, and then with calcium compounds in concrete, producing calcium carbonate, a benign chalk-like material.”

This process causes concrete to potentially act as a carbon sink. The researchers investigated the carbon uptake of all concrete pavements in the United States, running thousands of simulations to calculate the potential carbon uptake in each state based on road conditions, maintenance actions, budgets, and road lengths. The study found that after its 30-year analysis period, 5.8 million tons of CO2 could be sequestered, with 2.8 million tons of CO2 coming from the use phase and 3 million tons of CO2 coming from the end-of-life phase. The study also found that the carbonation process could offset 5% of the CO2 emissions generated from cement used in pavements across the United States.

Research by Anderson et. al shows that concrete’s rate of sequestration decreases with time. This happens because calcium carbonate begins to fill up void spaces in the concrete and slows its uptake of CO2. The carbonated surface can be removed, exposing uncarbonated concrete and beginning the carbonation process anew.

The simplest way of doing this is by diamond grinding—a technique that is commonly performed as part of pavement preservation. Diamond grinding has many benefits beyond renewing the concrete’s ability to carbonate, including keeping the road smooth and improving PVI as previously discussed. When states cover concrete pavement with asphalt overlays, carbonation is completely halted.

Social sustainability identifies and manages the impacts, both positive and negative, of industry on people. It also includes environmental justice, which refers to the fair treatment and meaningful engagement of all people regarding environmental protection. Pavements must fulfill their function of facilitating the movement of people and goods. When designed and constructed appropriately—with a focus on life-cycle—concrete pavements represent a socially sustainable choice because they provide a smooth, safe roadway, reduce hazards associated with work zones and support safety and wellbeing during disruptive events due to their ability to withstand, respond to, and recover rapidly.

A sustainable as well as resilient material, concrete is well-positioned to address the planet’s climate change considerations. R&B

This story was adapted from the ACPA white paper, “Concrete Pavement’s Role in a Sustainable, Resilient Future.”