New self-organized structures found in cement

CTS Cement Manufacturing Corp., Cypress, Calif., has announced the discovery of new structures in cement.

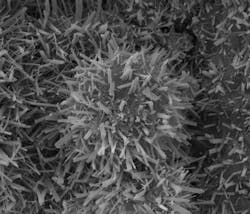

Discovered in mixtures of coal fly ash and hydrated calcium sulfoaluminate cement, these structures consist of micron-size glass spheres upon which needles have grown radially. Whereas these needles usually grow randomly in cement, they organize themselves as spines on round fly ash particles in fly ash-cement mixtures.

According to Dr. Eric Bescher, vice president for cement technology at CTS Cement, this is the first time these complex structures have been seen. These structures are very small, typically a few tens of microns in size, and can only be seen clearly under an electron microscope.

“We are excited about discovering these new self-organized inorganic architectures,” said Bescher. “Think of these structures as micron-sized sea urchins shells embedded in cement paste. We have some indications that they may play a beneficial role in the reinforcement of concrete or in shrinkage mediation. Our work is in progress and we are investigating the influence they could have on other properties of construction materials.”

CTS Cement is not aware of reports on similar structures in scientific literature to date. It is possible these structures grow and develop only in calcium sulfoaluminate/fly ash mixtures.

Bescher explained that the discovery is the result of attempts to make the company’s Rapid Set cement greener: “By substituting some of the Rapid Set cement with fly ash, we will further reduce the already minimal carbon footprint of the cement, while finding a use for a waste material,” said Bescher. “In this process, we stumbled onto something unexpected and exciting, the significance of which is to be determined.”

BescherBalls is CTS Cement’s working name for the new structures. The company is in the process of further investigations to understand their significance and the role they might play in construction materials.