Seeing a shrink?

Concrete bridge decks are susceptible to premature cracking and to corrosion of reinforcing steel.

Cracks in concrete can occur when a restrained mass of concrete changes volume, including drying shrinkage due to water loss. These types of shrinkage cracks can be counteracted with the use of shrinkage-compensating concrete (SC concrete). SC concrete is expansive cement concrete that when properly restrained from expansion, develops compressive stresses. The tensile stresses due to drying shrinkage or other factors have to overcome the compressive stresses and the tensile strength of the concrete for a crack to form; thus, crack formation is made difficult in these concretes. Two different SC concretes, which are commercially available, are based on calcium sulfoaluminate (Type K) and calcium oxide (Type G), respectively. The expansion in the Type K and Type G systems is driven by the formation of ettringite and calcium hydroxide, respectively.

K capitalization

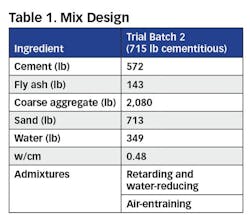

The bridge deck on the Rte. 613 bridge over the South Fork Shenandoah River in Warren County in the Virginia Department of Transportation’s (VDOT) Staunton District was selected for the use of Type K cement concrete. The bridge has four prestressed box beam spans, each 80 ft long. The bridge has a width of 28 ft and has no skew. A 5-in.-thick concrete overlay with corrosion-resistant reinforcement at a depth of 2.25 in. from the top surface of the deck was used. Type K expansive cement that was pre-blended was used rather than mixing the expansive additive with cement in the concrete mixing truck. The mix design used is shown in Table 1. Twenty percent of the total cementitious material was Class F fly ash. The water-cementitious materials ratio (w/cm) was 0.48. A higher w/cm is needed for Type K cement concrete for the ettringite formation and for maintaining workability.

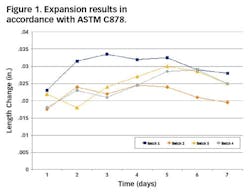

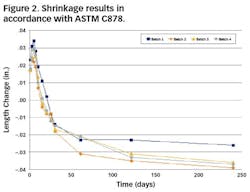

Concrete mixtures were collected from different truck loads, and specimens were prepared for hardened concrete testing. In the fresh state, the concretes were tested for slump (ASTM C143), air content (ASTM C173) and density (unit weight, ASTM C138). Hardened concrete specimens were subjected to compressive strength, elastic modulus and permeability testing. Restrained expansion was measured in accordance with ASTM C878. ASTM C878 test specimen is restrained using a threaded low-carbon ¼-in.-diam. rod and two end plates. Drying shrinkage and restrained expansion test specimens were subjected to seven days of moist curing. Permeability specimens were subjected to an accelerated moist cure for one week at room temperature and then three weeks at 100°F.

The concrete was placed by pumping. During the initial placement, the contractor used a 5-in.-diam. slickline that was reduced to a 4-in. diam. to pump the concrete. Blockage occurred in the slickline, and pumping was stopped. In addition, the concrete at the end of the slickline showed heavy segregation, and the entire mixture was removed. At the truck, the mixture looked cohesive, and no segregation was found. A severe slump loss and a temperature gain of 10°F occurred between the plant and the jobsite. The concrete mixture had a temperature of 85°F. It was further noted that the temperature of the aggregate stock pile was 94°F. There was no concrete placement on the deck on that day.

The contractor decided to use a continuous pump-line diameter of 5 in. with a higher pumping capacity. It also was decided by the research team and concrete producer to use a hydration stabilizer and a high-range water-reducing admixture. Proper mixing of the stockpile during watering would aid in the cooling of the aggregate for future projects.

The second placement occurred about a week later. Each truckload contained 8 cu yd of concrete (2 cu yd less compared to a regular concrete mix truck load). The average w/cm was 0.47. At the plant, the average slump was 8 in., the average air content was 7.7%, the average concrete temperature was 61°F and the average density was 146 lb/sq ft. Site properties were as follows: an average slump of 5.6 in., an average air content of 7.4% and an average concrete temperature of 70°F; air loss was minimal. The evaporation rate at the site averaged 0.017 lb/sq ft/hour, and slump loss averaged 2.4 in. from the plant to the site, with a drive time of 45 minutes.

The third placement occurred a week later. The average w/cm was 0.47. At the plant, the average slump was 7.3 in., the average air content was 8.2%, the average concrete temperature was 66°F and the average density was 147 lb/cu ft. Site properties were as follows: an average slump of 5.6 in., an average air content of 6.1% and an average concrete temperature of 68°F; average air loss was about 2% and was more than the previous placement. The evaporation rate at the site averaged 0.021 lb/sq ft/hour, and the slump loss averaged 1.7 in. from the plant to the site.

Wet Burlap placement immediately after screeding.

For the concrete temperatures below 68°F measured at the plant, the slump loss were below 4 in. Thus, if the slump values were kept above 8 in. at the plant, a minimum of 4 in. would be achieved at the jobsite, which was satisfactory for placement. SC concrete finished easily at these slump values.

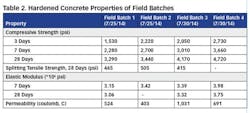

The hardened concrete properties for each batch are shown in Table 2. The average values for two batches each day were as follows: The average 28-day strengths were 3,370 psi (average of field batches 1 and 2) and 4,450 psi (average of field batches 3 and 4) for placements 1 and 2, respectively. The concrete strength was low in field batches 1 and 2 because of high air contents of 8.7% and 9%, respectively. The average elastic modulus and splitting tensile strength values were 3.37 *106 psi and 460 psi, respectively. Permeability values were very low and ranged from 403 C to 1,031 C, with an average value of 662 C. Average 28-day strengths for the district materials quality assurance samples (from three different truckloads) for placement 1 were 4,060 psi, 4,010 psi and 4,030 psi. The compressive strengths were expected to be lower than conventional deck concretes because of a higher w/cm; increased air contents also contributed to marginal strengths. The corresponding permeability values were 1,057 C, 1,055 C, and 1,013 C, respectively.

The expansion results during the moist curing period are shown in Figure 1. The ASTM C878 samples were initially measured six hours after sampling and then on one-day increments for seven days. Batch 2 specimens showed a lower expansion compared to others. The average seven-day expansion was 0.025%, with a maximum average value of 0.03%. Most of the expansion happens immediately after concrete sets, so the early measurement is critical in capturing the expansion.

After seven days, all samples were subjected to drying, and the length change results are shown in Figure 2. Normal shrinkage occurs when water starts to evaporate from the concrete surface. The results of the ASTM C878 test method showed that the drying shrinkage values after a 28-day drying period for all specimens were below 0.01%. For all specimens, 230-day shrinkage values were below 0.04%. These values are much less than typical portland cement mixes used in decks which are > 0.04% at 28 days.

Not as much

A field survey of the bridge deck was performed after six weeks to monitor cracking. During the inspection, two transverse cracks were found above pier 1 and pier 3. No other cracking was found at that time. The cracks over piers are very common due to negative moments. A second field survey was performed after 4.5 months. Several longitudinal cracks were found in the bridge spans. An additional transverse crack was also found above pier 2. Based on the locations of the cracks in the bridge deck overlay (directly above box beam connections), reflective cracking is considered to be the cause of the longitudinal cracking. This type of cracking appears to be caused by the differential movement of the beams at the keyway, and this relative movement between adjacent box beams is quite common. Another condition survey was conducted at an age of 15 months. There were several longitudinal cracks (reflective cracks) along the entire length of the bridge. The average widths of these cracks ranged from 0.1 mm to 0.3 mm. Map cracking was found in a couple of locations in the deck surface. More transverse cracks over the piers were observed (crack width of 0.1 mm to 0.2 mm) compared to the previous survey.

The results showed that a bridge deck with fewer transverse cracks than typically found in decks constructed with Type I/II cement can be constructed with Type K cement concrete. There were several longitudinal cracks (reflective cracks) caused by the differential movement of the beams at the keyway that could not be prevented by the use of SC concrete. No special construction equipment or techniques are required for satisfactory placement of SC concrete, but slump loss under hot weather conditions is a more serious problem in SC concrete than in normal portland cement concrete. Hence, for successful placement of Type K cement concrete, sufficient prior planning and proper mix design development are needed. Another concern is the availability and cost of Type K cement since it is not routinely used.