Caltrans increases traffic line width with high-profile striping on state highway system

Motorists across the state of California will notice a new generation of road striping on highways, freeways, and interstates that is wider, brighter, and long-lasting. The California DOT (Caltrans) has increased the width of all 4-in.-wide longitudinal traffic lines to 6-in.-wide high-profile striping on the state highway system.

The new 6-in.-wide, highly reflective road striping debuted in 2017 as part of the “Across the Top” I-80 project in Sacramento. Crews made various improvements across a 10-mile section of I-80, and the $136 million project was an ideal project to test the new striping since the interstate is heavily traveled and a main route to the capital city. Caltrans was able to see if the materials could sustain the wear and tear of heavy traffic, and monitor the durability and effectiveness of the new striping.

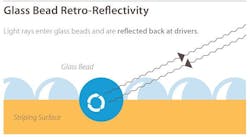

Using glass bead retro-reflectivity, light rays enter glass beads and are reflected back at drivers allowing motorists to better see the traffic lines on the road.

After seeing the success, Caltrans decided to re-stripe 50,000-plus lane miles of state highway system in the next decade with the new road demarcation lines replacing the longtime standard 4-in.-wide stripes. The 6-in.-wide striping consists of tape or thermal plastic embedded with glass beads. Both the thermoplastic material and tape used in striping contain tiny glass beads that enhance reflectivity, particularly when illuminated by vehicle headlamps or in rainy conditions. The materials have proven very durable and is expected to retain a minimum level of reflectivity despite constant heavy wear. However, not all parts of the state will see the new striping material because it will not be applied on roadways above 3,000 ft in elevation where snow removal equipment is used. The shovels that scrape snow and ice off the roadway would also remove the thermoplastic striping so Caltrans’ maintenance crews will continue to repaint those lines when damage occurs.

Also disappearing, as the new striping is laid, are the raised, non-reflective pavement markers known as Botts’ dots, named after the Caltrans scientist who invented them in 1953. With the advent of the new striping, the ubiquitous little bumps have outlived their usefulness as lane separators.

Caltrans has implemented the use of durable marking material by developing warranty-based performance specifications, permanent tape, methyl methacrylate (MMA), and thermoplastic with enhanced wet-night visibility. The marking selection guideline was developed to aid Project Engineers with the process of selecting traffic striping material on state highway systems. The marking material selection process is based on estimated remaining pavement service life, pavement type, climate, location, and the expected performance of the striping material.

Caltrans recognizes the potential cost-effectiveness and safety enhancement of wider traffic stripes and warranty-based markings on a system-wide basis. The Federal Highway Administration (FHWA) published a Supplemental Notice of Proposed Amendment (SNPA) to the Manual on Uniform Traffic Control Devices (MUTCD) in the Federal Register on January 4, 2017, regarding minimum retained retroreflectivity of markings. Based on this document Caltrans is adopting the policy to require minimum retained retroreflectivity levels of 100 mcd/m2/ls on its performance specifications for durable markings.

Based on the technical literature and agency responses, wider stripes improve driving conditions such as long-range detection under nighttime, stimulation of the peripheral vision, lane positioning, and driver comfort. Markings provide an important means of visually communicating how drivers must use a roadway safely. The new 6-in. striping, with its wider and brighter profile, is expected to enhance safety for older drivers and truckers as well as in challenging conditions such as rain. Per FHWA’s Handbook for Design Roadways for the Aging Population, the increase in the width of longitudinal traffic lines benefits older drivers and increases visibility of lane line delineation for all road users by providing improved roadway guidance, especially during periods of impaired visibility, such as wet night conditions.

Markings must be capable of conveying information during inclement weather and evening hours when there may be little to no illumination from overhead lighting. The 6-in.-wide striping provides a valuable continuous stream of information about the roadway that signs or signals cannot supply. They alert drivers to changes in the roadway and help them maintain their position inside of the lane without requiring the driver to take their eyes off the road. Striping is used to separate opposing traffic streams and channel traffic into the proper roadway positions. When motorists operate a vehicle, they use markings to guide them through the roadway.

More visible markings with wider widths and higher retroreflectivity can increase the distance with which the lines are detectable and may improve a motorists’ ability to perceive the marking in their peripheral vision. These enhancements improve lane keeping and positively impact safety.

Texas A&M University’s Transportation Institute (TTI) found in a study “An Evaluation of the Effectiveness of Wider Edge Line Pavement Markings” that wider traffic stripes on roadway shoulders (edge lines) reduce crashes and fatalities. This study analyzed FHWA data from Kansas, Michigan, and Illinois. The evidence all supported the adoption of wider edge lines

When crews replace the longtime standard 4-in.-wide stripes with the new standard, crews will first remove the old lines from the roadway, then sweep the roadway clean before adding primer and painting the new lines with a striping truck. Caltrans will then add the tiny beads of glass. The paint is dry enough so it will not smear. The paint typically dries completely in 10 minutes.

The old 4-in.-wide striping and Botts' dots will be replaced with the new 6-in.-wide striping

Thirty-three states in the U.S. use wide stripes (5 to 8 in.) with no documented safety issues. Caltrans has used wider stripes for bike lanes, high-occupancy vehicle (HOV)/carpool lanes, and channelizing lanes for years with no documented safety issues.

In addition to requiring wider and durable traffic stripes, Caltrans is developing guidelines and procedures to maintain markings on state highway systems. Caltrans Division of Maintenance is developing the guidelines on methods for monitoring and maintaining marking durability and retroreflectivity.

For FY 2017-2018, Caltrans delivered 35 striping contracts for 17,500 total lane miles with a total value of $210 million. These projects used warranty-based specifications on lane lines where the pavement service life was greater than five years. For pavements with service life of five years or less, other durable material was used. For edge line striping, Thermoplastic, MMA, and two component paints were used. For striping projects at above 3,000 ft, recessed markings were used.

In the next few years, all of the state’s 27,000 lane miles that make up the freight corridors—Interstates 5, 10, 15, and 80—will be restriped. It is expected that all of the state highway system will be restriped within a decade, funded in part by revenues from Senate Bill 1 (SB 1), the Road Repair and Accountability Act of 2017. SB 1 was signed into law on April 28, 2017, and the legislative package invests $54 billion over the next decade to fix roads, freeways, and bridges in communities across California. These funds will be split equally between state and local investments. It will address the backlog of repairs and upgrades, while ensuring a clearer and more sustainable travel network for the future. California’s state-maintained transportation infrastructure will receive roughly half of SB 1 funds, approximately $26 billion, while the other half will go to local roads, transit agencies, and expansion of the state’s growing network of pedestrian and bicycle routes. Each year, this new funding will be used to tackle deferred maintenance needs, and approximately $1.8 billion will go towards maintenance and rehabilitation of the state highway system. In fact, by 2027 Caltrans is committed to repairing or replacing 17,000 miles of pavement. As crews are repairing and replacing the pavement on the state highway system, Caltrans is restriping the roads with the new 6-in.-wide striping standard. The 6-in.-wide highly reflective striping does not only enhance safety on the state’s highway system but meets the needs of new technology.

As Caltrans prepares for future innovations and technologies, the department has been proactive in reaching out to transportation industry leaders. Caltrans consulted with auto manufacturers Tesla and Google, two major players in the autonomous vehicle industry, about the striping changeover. Autonomous vehicles feature configured sensor technology that reads markings. Camera technology can detect the edge lines, lane lines, center lines, and other markings. Wider longitudinal lines and high-performance markings increase the detection rates of camera technology that facilitate the autonomous vehicle implementation in the California highway system. The 6-in.-wide highly reflective striping will be a better roadway guide for autonomous vehicles than the 4-in. striping.

Caltrans’ goal is to enhance safety on California state highways and make it easier to navigate no matter what time a person travels. In the past, fog and heavy rain have hindered motorists’ abilities to see the striping on the road so it is Caltrans hope that the highly reflective 6-in. striping will provide more visibility. With the new material being used to enhance reflectivity and the light rays from vehicle headlamps that project off the glass beads, the white 6-in. reflective striping will shine a safe passage for motorists traveling in the Golden State.