Connecticut DOT making progress on Walk Bridge replacement

Few are the bridges in the U.S. that have been around as long as the Norwalk, Conn., Walk Bridge. The 122-year-old structure has been a stalwart corridor, carrying rail traffic on Metro-North’s New Haven Line as well as Amtrak service on the Northeast Corridor that serves passengers traveling between Boston, New York and Washington, D.C. Now, after years of discussions, delays and distress, the replacement of the Walk Bridge has begun to come into focus.

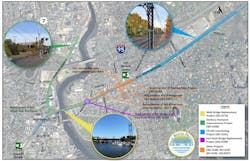

The new bridge, which according to the Connecticut Department of Transportation is 60% designed, will cost an estimated $511 million, as part of an overall $1.2 billion package that also includes:

• The replacement of the Fort Point Street Bridge;

• The replacement of the 100-year-plus-old East Avenue Railroad Bridge, which also will involve a number of roadway improvements and upgrades to the East Norwalk Station;

• The CP243 Interlocking Project, which will facilitate construction of the new Walk Bridge by allowing trains to switch tracks and maintain service during the two-track outage; and

• The Danbury Branch Dockyard Project, which will electrify about a mile of tracks on the southern portion of Metro-North’s Danbury Branch to increase operational flexibility. As part of the Dockyard Project, the Ann Street Bridge is being expanded from two to three tracks to provide train storage.

The need for a new Walk Bridge became apparent in 2014, when the swing-arm bridge twice failed to close, disrupting travel on the New Haven Line, the nation’s busiest commuter line. A year later, plans were announced to begin construction on a new bridge in 2016, with a completion date of 2020.

While work on the $242 million CP243 and the $98 million Dockyard Project began in October, construction of the new Walk Bridge is now expected to begin in late 2019, though no significant construction will occur until about 2020. The entire project is expected to take four or five years to complete.