Missouri short span bridge study finds steel saved 25% over concrete

If you think it costs more to use steel for a short span bridge project, it is time to think again, based on the results of a study that compares nearly identical short span steel and precast concrete bridges in Missouri.

The study was undertaken by Michael G. Barker, Ph.D., P.E., a professor in the College of Engineering and Applied Sciences at the University of Wyoming, and Missouri bridge engineering consultant John Mann, P.E., to perform a true “apples-to-apples” comparison of superstructure costs for steel versus precast concrete in short span applications. The study also included the total construction costs for the project.

The structures included one steel beam bridge and one hollow core slab precast concrete bridge that were nearly identical in all aspects. They were both built in 2012 with the same location and topography and with nearly identical roadway length and width, abutments, structural depth, and guardrail systems. The same local work crew was used to build both bridges.

In a side-by-side comparison of construction square footage costs, the steel short span superstructure provided a 25.8% cost savings, with an overall 19.3% savings in the total cost of the structure.

Audrain County Steel Bridge 411 has a 47.5-ft span and 24-ft roadway width with a 2-ft structure depth plus slab and no skew. The basic superstructure design consists of four weathering steel stringers. The total cost for the project was $111,853 ($97.48 per sq ft).

Audrain County Concrete Bridge 336 has a span of 50.5 ft with 24-ft roadway width and 2-ft structural depth on a 20-degree skew. It consists of six hollow core precast slab girders. The total cost for the project was $154,035 ($120.83 per sq ft).

In both cases, Audrain County engineers tracked detailed costs for all components of the bridges from the beginning of design to the end of construction. All superstructure-only costs were tracked separately for the “apples-to-apples” comparison.

Audrain County Concrete Bridge 336

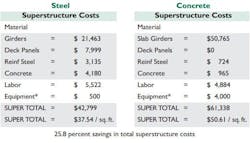

When all of the actual costs were tallied, the short span steel bridge superstructure-only construction savings were 25.8% in comparison to the precast concrete superstructure. The Steel Bridge 411 superstructure cost—including material (girders, deck panels, reinforcing steel, and concrete), labor, and equipment—came to $37.54 per sq ft. The Precast Bridge 336 superstructure costs—which included material (slab girders, reinforcing steel and concrete for parapet walls and grout), labor, and equipment—came to $50.61 per sq ft.

The lower price per square foot for the steel bridge was due to the steel girders being less than half the price of the slab girders. Crane costs also created some of the savings. With the steel bridge, Audrain County used its own 30-ton crane, but had to rent a 100-ton crane to handle the heavier load for the precast bridge. The two-day rental and miscellaneous equipment cost was $4,000, compared to $500 for miscellaneous equipment for the steel bridge.

“In our experience, a short span bridge in the range of 50 ft is almost always the best value when constructed of steel," Mann said. "At 70 ft or longer, we’ll perform a more in-depth analysis to evaluate variables, such as proximity to the precast plant and overall cost. There are some cases where we consider precast hollow core slabs for a super-fast turnaround, but we know we’ll have to pay a premium. Overall, I’ve found that steel is the better buy.”

Over a span of several years, Audrain County constructed five short span steel bridges with an average length of 53 ft for an average total project construction cost of $86.09 per sq ft. In that same time, the county constructed four concrete bridges with an average length of 37.5 ft for an average total project cost of $96.32 sq ft.

To summarize, bridge owners and consultants will find that steel bridges are competitive and often more economical than concrete bridges.