Improvements to deck leaves Colorado bridge stronger, safer

Located on a rural portion of I-76 in eastern Colorado, a bridge near the town of Hudson needed infrastructure protection and safer winter-driving conditions. When the University of Colorado, Denver, wanted to conduct a study involving the effects of an anti-icing pavement installation, the bridge near Hudson offered the perfect location.

“The eastbound and westbound bridges by Hudson had weather-monitoring systems already installed, so the location made sense,” said John Elshof, maintenance supervisor for the Colorado Department of Transportation (DOT). “We had two control subjects right next door to each other under the same conditions.”

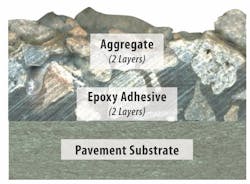

The pavement overlay the Colorado DOT installed on the eastbound bridge deck is called SafeLane surface overlay and is produced by Cargill Deicing Technology. The overlay is comprised of epoxy and aggregate to help ensure infrastructure protection from damaging corrosion, increase surface traction and prevent ice formation.

Since the installation and completion of the UC Denver study in 2010, the Colorado DOT has noticed significant infrastructure protection and safer winter-driving conditions on the bridge deck.

“Bridges are notorious for being a problem in winter weather,” Elshof said. “And one of the biggest advantages that came out of this installation was protecting the deck from water seepage–it’s drastically reduced the amount of moisture that gets through the surface.”

As well as greater infrastructure protection, the pavement overlay additionally provides reduced snowpack and frost formation on the driving surface. The aggregate in the surface can store deicing and anti-icing liquid and naturally release it to the surface when temperatures drop below freezing. This process helps prevent slippery conditions, such as the formation of frost, ice and snowpack.

“When we pre-treat the bridge, we go out a day or two before a storm is supposed to hit and put down mag-chloride,” Elshof said. “The aggregate holds on to the liquid and it doesn’t start working until precipitation starts. Once the event begins, the anti-icing starts to take effect, which gives us time to get out there with a plow or a sander.”

And while the Colorado DOT is enjoying greater infrastructure protection and less snowpack on the surface, they’re also enjoying the cost savings of pre-treatment practices and prolonging structure life of the Hudson-area bridge.

“We’re extending the life of our bridge, and a new bridge would cost millions,” Elshof said. “Plus, we’re also saving on time, labor and materials. It’s not like we have this miracle tool that keeps bridges dry, but we do have a tool that allows us to keep a bridge in a safer condition much longer.”