Modified Concrete Suppliers turn to Trinseo’s Modifier A™ / NA Latex concrete modifier to ensure success in the competitive bridge deck rehabilitation market.

Addressing Rapidly Aging U.S. Infrastructure

As U.S. infrastructure continues to age, the nation is grappling with the significant volume of repairs and financial investment required to improve conditions. In fact, according to the American Road & Transportation Builders Association, nearly one-third of all U.S. bridges, approximately 220,000 bridges, require major repair work or should be replaced. In the face of this dilemma, bridge repair contractors and engineers need proven solutions that effectively restore and maintain bridge integrity long-term.

With decades of experience preserving bridge decks, Modified Concrete Suppliers has made a name for itself in the industry as a producer of Latex Modified Concrete (LMC), a high-performance overlay material. Since its founding, the company has supplied hundreds of thousands of cubic yards of LMC to support bridge repair projects in over 25 states. Their strategy for success centers on combining their expertise with industry-leading, proven materials to tackle bridge repair projects quickly and effectively, with long-term results that stand the test of time and mother nature.

Answering Diverse Challenges

The highly competitive bridge deck rehabilitation market favors the lowest bidder with new project contracts. In addition, contractors and companies must contend with tight timelines, unpredictable weather patterns, materials shortages, and countless other market fluctuations that impact their competitiveness and profitability. To keep up with the industry and be successful, they must propose repair solutions that ensure superior quality and safety and promise long-term results at a competitive price.

Many products on the market are not up to the challenge. For example, microsilica concrete has left some contractors addressing complications with cracking, inconsistent mixing, and other performance problems. In some cases, this has necessitated further replacement and repair. Other examples are epoxy concrete, polyester polymer concrete, and ultra-high-performance concrete (UHPC). Unfortunately, none of these competing technologies have the proof of longevity to compete with LMC, which has effectively been used to repair bridge decks since the late ’50s.

The Superior and Proven Choice

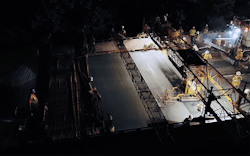

When presented with a high-profile bridge repair project with the Indiana Department of Transportation that required a quick turnaround, Modified Concrete Suppliers turned to Trinseo’s Modifier A™ / NA Latex, a trusted concrete modifier that has proven its value over the years with field trials dating back to the late 1950s.

Modified Concrete Suppliers chose Modifier A™ / NA Latex because it is a superior latex for bridge deck rehabilitation. LMC is known for outlasting competitive technologies with a significantly longer lifespan that adds to the sustainability of projects and contributes to long-term cost savings. Furthermore, it is a consistent, reliable technology with over seventy years of proven performance and value.

Studies prove Modifier A™ / NA Latex offers superior performance compared to alternatives, including reduced shrinkage, excellent adhesion of the overlay to the bridge deck, low permeability, reduced modulus of elasticity, reduced crack propagation, improved wear resistance, quick curing capability, and lower cost over the life of the project. In addition, Modifier A™ / NA Latex is manufactured to meet the Federal Highway Administration’s (FHWA-78-35) latex specifications and concrete performance requirements.

Longevity in Action

At the conclusion of the project, Modified Concrete Suppliers completed its scope of work on time, on budget, and within the necessary technical specifications for LMC solids and air content. In addition, the LMC overlay on the repaired bridge deck is expected to last between 30-40+ years—significantly longer than other competitive bridge deck overlay solutions—and Modified Concrete has previous project examples where this longevity promise is validated.

Modified Concrete benefited from Trinseo’s responsive technical support and on-time deliveries throughout the project, which helped them stay on track for successful project completion.

Editor's Note: Scranton Gillette Communications and the SGC Infrastructure Group are not liable for the accuracy, efficacy and validity of the claims made in this piece. The views expressed in this content do not reflect the position of the Roads & Bridges' Editorial Team.