For decades, the standard coating system for steel bridges has been a three-layer system consisting of an organic or inorganic zinc-rich primer, epoxy intermediate coat, and polyurethane finish coat, with each layer providing specific protection mechanisms to prevent corrosion. Since then, advancements in coating resin technology have improved painting efficiency, allowing a reduction in the number of coating layers from three coats to two through the use of high-build, two-coat polyaspartic urethane (PAS) coating systems.

Polyaspartic coatings offer a number of application and physical property advantages compared to traditional coating systems such as a fast cure with a reasonable pot life. Polyaspartic coatings can also be applied at higher dry film thicknesses. The larger film build tolerance of PAS coatings allows for more forgiving application when painting complex geometries, offers better edge retention, and enables a reduction in number of coats needed to provide substantial corrosion protection. Additionally, polyaspartics offer color and gloss retention equivalent to that of polyurethane systems. These property advantages of PAS coatings have been documented to increase painting productivity and reduce project costs, all without sacrificing corrosion protection.

In 2005, the Virginia DOT (VDOT) decided to use a PAS two-coat system in lieu of a three-coat system on 17 bridges due to its faster blast/repaint time, which significantly lowers traffic redirection costs. After 10 years of service, a field performance comparison study was done on a number of these PAS two-coat systems and three-coat moisture-cure urethane (MCU) systems on steel bridges in western Virginia. The service conditions for this environment included routine salt application during winter and frequent freeze/thaw cycles during spring and fall seasons that stress the ability of coatings to protect the steel.

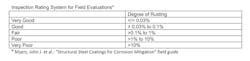

After the inspection of eight steel structures coated with PAS systems, it was found that the PAS two-coat system performed well with four rated Very Good, three rated Good and one rated Fair. The seven structures rated Very Good and Good are expected to be excellent candidates for overcoating after 20 years, performing similar to or better than the MCU three-coat bridges. The two-coat system performed as expected based on previous evaluations of these systems.

When it comes to the proven benefits of polyaspartic coatings, this research confirmed the field performance of PAS two-coat coating systems and further validated the technology’s excellent corrosion prevention noted in many previous investigations. With performance being equal, PAS two-coat systems can provide significant value to bridge owners in the form of 20% overall cost reduction in painting operations, 31% labor reductions and accelerated painting schedules, and milder traffic congestion headaches—all while offering excellent corrosion protection to support beautiful, durable, and lasting infrastructure.

Editor's Note: Scranton Gillette Communications and the SGC Infrastructure Group are not liable for the accuracy, efficacy and validity of the claims made in this piece. The views expressed in this content do not reflect the position of the Roads & Bridges' Editorial Team.