Stabilized FDR material outperforms non-stabilized FDR material in Minnesota

Tim Erickson, Lake of the Woods County, Minn., engineer, was looking for the best solution to rehabilitate County State Aid Highway (CSAH) #8. This was a 5.2-mile project in the heart of the county’s fishing resort and agriculture industries. It was crucial that whatever the county did to address the aging infrastructure, it needed to result in a final product that would allow the county to not have to significantly disrupt this area again for the long term.

County officials decided to add Team Laboratory Chemical Corp.'s BASE ONE base stabilizer to this full-depth reclamation (FDR) project to increase the performance of the existing material.

In the summer of 2017 the road was reclaimed with 4 in. of old bituminous and 4 in. of underlying aggregate base on the first pass to create a 50/50 blend of an asphalt and aggregate mix. Then the BASE ONE stabilizer was injected into the top 4 in. of base material on the second pass with the reclaimer. A pad foot compactor followed for the initial compaction. The surface was shaped with a motor grader and compacted to density with a rubber-tired roller. The project was completed by adding a 4-in. bituminous surface. This was the county’s first experience with BASE ONE, so officials wanted a test strip to compare the results of adding BASE ONE versus non-stabilized FDR under the exact same traffic conditions. The BASE ONE stabilizer was not added to the last 1/4 mile of the project to give crews that test strip.

In the spring of 2018, the road was tested using the data from the Frozen Soil Profile. On May 23, 2018, American Engineering & Testing Inc. conducted a falling weight deflectometer (FWD) test and used ground-penetrating radar on the roadway to collect data.

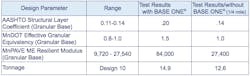

The results are shown in the table below.

This gave county engineers a unique opportunity to see how the stabilized FDR with BASE ONE and FDR without BASE ONE performed on the same road.

“As you can see in the chart, the stabilized material greatly outperformed the non-stabilized material in all categories, giving us the additional performance we were looking for,” Erickson concluded.