By: John Bullough, Ph.D.; Contributing Author

Nighttime work zones along roadways can be challenging environments for workers and drivers alike. Setting up and taking down the trailer-mounted light towers used by many construction workers is time-consuming and tedious. Aiming the lights on these towers to maximize visibility while preventing glare can be difficult, if not impossible.

Flashing warning lights capture attention but can be distracting or dazzling. Signs to help guide drivers through the work zone are often present but may be in unexpected locations. Topping it all off, work zones often mean familiar traffic patterns are changed, lanes are closed and speed limits are reduced, potentially contributing to confusion by drivers. Together, all of these factors can create visual chaos for both drivers and workers alike in work zones.

Balloon-lighting systems were determined to have lower brightness and to produce softer shadows than conventional roadway lighting. Photo courtesy of Dennis Guyon.

Fortunately, a wide variety of new technologies are emerging to help tame and overcome the potential for visual chaos. Examples include balloon-lighting systems, light-emitting diodes (LEDs), new retroreflective and luminescent sheeting materials, temporary pavement markings, and synchronized or sequentially flashing lights. There is, however, little guidance for integrating these new technologies into nighttime work zones. In response to this knowledge gap, the New York State Department of Transportation (NYSDOT) initiated a research project to identify, evaluate and demonstrate approaches to nighttime highway construction illuminance and visual information.

In this project, a research team from the Lighting Research Center (LRC) at Rensselaer Polytechnic Institute surveyed traffic engineers and construction firms, assessed worker and driver responses to different lighting conditions, and measured the performance of different products and systems. The LRC also conducted full-scale mock-ups that allowed individuals from NYSDOT and other organizations to see these systems live and in person. The types of lighting and visual information systems evaluated fell into three primary categories: illumination for worker visibility; signage and marking for driver information and hazard detection; and flashing signal lights for attention-getting and channelization of traffic.

Avoiding the ratchet effect

First and foremost, illumination systems are used in nighttime work zones to support worker visibility. Current requirements for light levels in work zones at night typically specify levels of at least five footcandles on the ground or work surface, with up to 20 footcandles for work involving very detailed visual tasks. These levels are five to 10 times higher than levels specified for roadway and pedestrian areas outdoors. Why? In part this is because the tasks many workers perform in work zones are challenging, but also it seems to be a response to the inherently glaring lighting systems often used in these locations. It is extremely challenging to avoid glare when using trailer-mounted light towers.

Because of the way the human eye works, it is possible to reduce the glare from a bright light in one of two ways: Either reduce the intensity of the bright light (this is the most obvious solution), or increase the ambient light level (this is why automotive daytime running lights viewed at night can be very uncomfortable, but the same lights are not bothersome during the day). In principle, using higher light levels on the ground from light towers will increase the overall ambient light level, potentially reducing glare, but it also is likely to direct more and brighter light into workers’ eyes. So ambient light levels on the ground are increased, but glare is increased again, and so on, and so on. This ratcheting of light levels is a phenomenon experienced not only in work zones but in other forms of outdoor lighting, which besides wasting energy and fuel can contribute to unwanted light trespass and other nuisances.

Returning to the purpose of work-zone illumination, how much light do workers need in order to see? The LRC began answering this question by performing visibility analyses using a validated computational model of visual performance. Visual performance depends on the light level, the contrast between an object and its background, and the size of the object—as well as a person’s age and the presence of glare. The analyses showed that even for older workers, most tasks were highly visible under just one or two footcandles of illumination, if glare could be reduced.

When different types of illumination were set up along a roadway in the full-scale demonstration, observers ranging in age from their 20s to their 70s judged balloon lights, having lower brightness and producing softer shadows than conventional light towers, to reduce glare and produce excellent visibility even where light levels were one footcandle or lower, confirming the visibility analyses. Ground-level lighting, if it provided diffuse shadow-free illumination, also was judged favorably. Overall these efforts demonstrated that with proper glare control, light levels in work zones do not need to ratchet up to ever-increasing levels.

Getting visual

Both drivers and workers need clear visual information when working in and navigating around work zones. Signs, temporary roadway delineation and the marking of potential hazards such as trailers and inactive equipment are all critical for worker and driver safety. Studies by the LRC showed that if the brightness of sign characters and delineators was at least three times higher than their backgrounds, they could be identified quickly and accurately. Hazard markings needed to be five times brighter than their backgrounds, probably because hazards are less likely to occur in places where they are expected.

Measurements of the brightness of conventional and highly reflective sign-sheeting materials under high- and low-beam headlight illumination confirmed that they produced sufficient brightness for quick and accurate identification whether used for signage, delineators such as barricades or barrels or hazard markings. In very bright, complex work zones, materials with higher reflectivity will stand out better than engineering grade materials used in less active areas. In a full-scale mock-up demonstration, these sheeting materials were evaluated and found to provide excellent visibility. In fact, under otherwise dark conditions some of the highly reflective sheeting materials could appear too bright. The demonstration also included temporary pavement marking tape for wet conditions and observers judged that these wet reflective tapes indeed maintained their brightness when wet, while economical grade tapes did not.

Photoluminescent materials, which emit light following exposure to light, have been improving, and these also were evaluated and demonstrated. Photoluminescent paint appearing yellow under daylight and emitting yellow-green light in the dark was bright enough to be visible after several hours following exposure to light. Although the photoluminescent emission was not bright enough to stand out in active, illuminated work-zone areas, it was judged as easy to see in dark locations, such as storage areas for construction materials where high light levels would not otherwise be necessary but where avoiding tripping hazards is important.

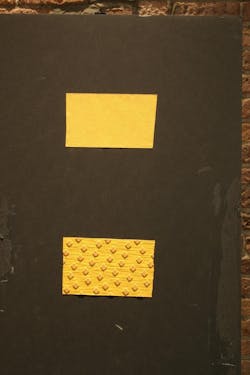

The standard orange work-zone sign-sheeting material in the lower panel was compared to newer retroreflective materials in the upper panels.

Left: Economical grade pavement marking tape (top) was compared to wet-reflective marking tape (bottom).

Right: Observers viewed several photoluminescent tape and paint samples.

Driver communication

Flashing and steady-burning signal lights are used in work zones to capture drivers’ attention and provide warnings such as information about closed lanes ahead or slow-moving vehicles and equipment in or near the right-of-way. Experimental studies confirmed that flashing lights were judged as clearer and more meaningful when the flashes of light were synchronized or in sequence, rather than occurring randomly.

In a full-scale mock-up demonstration, observers judged barricade lights meeting Type A (flashing) or Type C (steady-burning) requirements as bright enough for dark locations but not necessarily for bright, lighted areas. Type B flashing barricade lights were judged as bright enough for a lighted area, but if the intensity of barricade lights exceeded the requirements for Type B flashing lights, they began to be judged as too bright. A unique barricade light that “sweeps” from left to right or vice versa was judged to be helpful in conveying the need for shifting lanes by showing which direction drivers should move toward.

Putting the pieces together

Based on the results of the analyses and the findings from the full-scale demonstrations conducted using each type of work-zone illumination and visual information, the LRC developed a checklist for NYSDOT to assist in the planning and selection of lighting, sign and delineation materials, and warning signals to be used in nighttime highway construction work. The checklist includes factors such as the duration of the project, complexity of the roadway location, the presence (or not) of physical barriers separating traffic from the work location, and whether the project involves lane closures. Additional guidance includes a method for estimating the visual performance by workers under different light levels when they are performing tasks with different characteristics (e.g., large tasks where fine details are unimportant, versus small, detailed tasks where acuity and seeing small details are critical).

A technical report detailing the study background, the technical activities undertaken to understand how to support worker and driver visibility without contributing to excessive glare, and the full-scale demonstration activities has been completed and is available on the NYSDOT website at: www.dot.ny.gov/divisions/engineering/technical-services/trans-r-and-d-repository/

C-08-14-FinalReport.pdf.

This study was sponsored by the New York State Department of Transportation, and funded in part with state planning and research funds from the Federal Highway Administration. Janice Methé from NYSDOT served as project manager. The project was conducted through the University Transportation Research Center at the City University of New York. Performance Indicator LLC provided in-kind support of the project. Nicholas Skinner, Jeremy Snyder, Ute Besenecker and Mark Rea from the Lighting Research Center at Rensselaer Polytechnic Institute made important technical contributions to the project. ST

About The Author: Bullough works for the Lighting Research Center at Rensselaer Polytechnic Institute.