Shadow stretching

The safety of many short-term, short-duration and mobile work-zone operations is enhanced through the use of shadow vehicles and truck-mounted attenuators (TMAs).

Shadow vehicles and TMAs are deployed upstream of these operations to protect work crews on foot from a vehicle intruding into the work space. Shadow vehicles and TMAs also reduce the severity of an impact to intruding vehicle occupants relative to what would likely occur if that vehicle hit work equipment or materials in the work space. The FHWA Manual on Uniform Traffic Control Devices (MUTCD) identifies a number of typical applications where shadow vehicles are required.

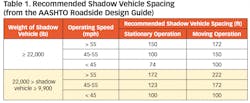

The position of the shadow vehicle and TMA relative to the work operation is important. The shadow vehicle should be positioned far enough upstream of the work operation that an impacting vehicle will not push the shadow vehicle into the work crew. At the same time, care must be taken not to position the shadow vehicle so far upstream that traffic going around it can move back into the closed lane and intrude into the work space. Existing guidance in the AASHTO Roadside Design Guide provides shadow vehicle spacing recommendations for two shadow vehicle size ranges at either stationary or slow-moving work operations (see Table 1). These recommendations imply that roll-ahead/skid-ahead distances in the event of a rear-end crash will be less than the spacing and keep the shadow vehicle from entering into the work space. Crash studies that have been performed with typical-size vehicles (i.e., 4,400-lb automobiles) have shown that roll-ahead/skid-ahead distances do not exceed these values.

Some agencies and contractors position their shadow vehicles based on this guidance. Other agencies have adopted different spacing criteria. In some cases, a longer spacing is called for, such as during paint-striping operations. In other instances, a shorter spacing is specified, as short as 30 ft in some cases. In most cases, the size of the shadow vehicle used is not mentioned, and the decision of what type of vehicle to use as a shadow vehicle is left up to personnel in the field.

The challenge

As mentioned above, these recommended spacing values were derived from crash test results performed with automobiles (4,400 lb). Today, many facilities serve a significant percentage of large trucks in the traffic stream, and have operating speeds of 70 mph or greater. A rear-end collision at that speed by a fully loaded large truck (80,000-lb gross weight) into shadow vehicles of the weights listed in Table 1 will likely result in roll-ahead/skid-ahead distances that are much greater than the current guidance. As an example, Figure 1 (on Page S14) presents an engineering analysis of the expected roll/skid distance required to dissipate the kinetic energy of a large truck to shadow vehicle rear-end collision at different impact speeds and shadow vehicle weights. The analyses suggest that roll/skid distances will greatly exceed the recommended Roadside Design Guide spacing, especially for lighter-weight shadow vehicles. Anecdotal information provided by manufacturers of TMAs suggests that shadow vehicles are getting hit more and more frequently by large trucks, and the results are indeed often quite severe. The only way to reduce these distances in the event of such a collision is to increase the size and weight of the shadow vehicle used.

Weight is your friend

Unfortunately, many work crews do not give much consideration to the shadow vehicle being used. On many high-speed facilities, large trucks make up to 50% or more of the traffic on the roadway, especially at night. In these situations, agencies and contractors would be better protected by using shadow vehicles that weighed at least 50,000 lb (such as a sand-loaded dump truck with a TMA), and/or increasing the spacing. Of course, a longer spacing may increase the potential for motorists to incorrectly cut back into the convoy rather than waiting until passing it entirely. In these cases, it may become necessary to employ multiple shadow vehicles at closer spacing. A rear-end collision with a large truck might then push the first shadow vehicle into the second shadow vehicle, but would likely not push the second shadow vehicle all the way into the work space where workers are present.

Those responsible for making decisions on the type of shadow vehicle to use during work operations should begin to consider using heavier shadow vehicles when performing work operations on roadways with significant amounts of high-speed truck traffic. It is important to note that a decision to use a heavier shadow vehicle does require that proper attention be given to the type of TMA used with it so that the consequences of any smaller vehicles impacting the shadow vehicle are not adversely affected. In addition, care must be exercised to ensure that any weight added to the shadow vehicle is properly attached or is otherwise contained within it, so that proper energy dissipation occurs if it is impacted from behind by a large truck.

Making intelligent equipment decisions such as this will yield demonstrable increases in worker safety and improve the overall operation of a work site.