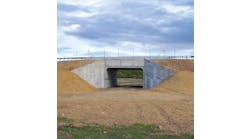

The Jericho Bridge, carrying County Road 12 (Greenbrier Road) over the Little Muskingum River in Monroe County, Ohio, was originally constructed in 1936 as a Works Progress Administration project (WPA Project No. 11220). Using the predominant technology of the time, workers erected a single-span, reinforced-concrete, open-spandrel arch bridge over the river, thereby connecting various parts of the rural countryside.

Reinforced with steel bars, the concrete bridge served the area for 70 years, but by 2006, its historical integrity was listed as “poor” by the Ohio DOT due to broken railing on the east, leaving an exposed hole in the center of the bridge and an excessive amount of moss growth underneath the bridge. And by 2011, the bridge supports were also deteriorating. Through the efforts of the Civil Engineering Department of Monroe County and supportive citizens, the state awarded a grant for the historical restoration of the bridge. The public bid for the project was won by Suburban Maintenance & Construction Inc. (SMCI) of North Royalton, Ohio, who recommended MAPEI products.

Monroe County Engineer Lonnie Tustin was onsite as the SMCI crew began to remove the debris of the crumbling railings and parapet walls on the bridge, noting that 3- to 4-in. rocks had been used as part of the aggregate in the concrete. “This was perhaps a mark of the lesser knowledge about concrete at the time when the bridge was originally constructed, and it probably contributed to the deterioration of the railing,” he said. The slab deck was also compromised, according to SMCI project manager Eric Urdzik.

Additionally, the concrete arch, abutments and columns of the substructure—as well as the walls and deck of the superstructure—were delaminated and needed concrete repairs and structural strengthening. “The complex part of the job involved the different kinds of repairs that were made,” Urdzik said. These repairs included demolition of the deteriorated superstructure and a form-and-pour process to produce a new parapet while maintaining its historical look. The bridge was widened on each side and arch columns required shotcrete repairs, followed by the application of MAPEI’s FRP products for structural strengthening of the arch and column members. SMCI MAPEI’s FRP line for the job included: MapeWrap Primer 1, MapeWrap 31 resin, MapeWrap C Uni-Ax 300 carbon fiber fabric and MapeWrap G Uni-Ax E-glass fiber fabric.

Together, the MapeWrap family formed an externally bonded FRP reinforcement system engineered to increase the strength of existing structural elements (without increasing the dead load supported by the structure) and improved the seismic performance of concrete columns, masonry and concrete walls, and concrete beam-column connections.

SMCI acted as general contractor and installer on the Jericho Bridge project, doing 100% of the work in a turnkey job. The bridge was in active use during renovations, and traffic continues to cross daily. The Jericho Bridge project was awarded the Historic Bridge Award by the Federal Highway Administration, the Ohio DOT, and the Ohio Historic Preservation Office.