Running back guarantee?

After federal regulations resulting from the Intermodal Surface Transportation Efficiency Act of 1991 (ISTEA) lifted a long-standing ban on using pavement warranties, many states across the U.S. experimented with various types of warranties.

Prior to ISTEA, the Federal Highway Administration (FHWA) had ruled that warranties essentially constituted maintenance activities, which could not be financed with federal-aid funds. Provisions in ISTEA, as well as a 1995 Interim Final Rule (IFR) fully adopted in 1996, allowed states to use warranties on any federal-aid project. Interest was spurred even more by a report from a 2003 scanning tour of Europe that focused on European use of pavement warranties, where several countries had used various types of warranties for as long as 30-40 years.

The Indiana Department of Transportation (INDOT) was among the states that piloted the use of asphalt pavement warranties, letting the first of these projects in 1996. In all, 10 asphalt warranty projects, with warranty periods of five years, were constructed between 1996 and 2007 on interstates across the state. Interest in the warranty specification waned by the mid-2000s and the specification was eventually abandoned. Reportedly, this was due to an attempt to increase the warranty period to 10 years. Now, some 20 years after its first warranty project, INDOT is actively examining options to reinstate a warranty program for asphalt pavements.

This renewed interest was stirred, in part, by the findings of a recent research project exploring the long-term performance of Indiana’s warranted asphalt pavements compared to similar pavements constructed under conventional specifications. While two previous research projects had evaluated the performance and cost effectiveness of the warranty projects, those earlier studies were short-term. The recent study, sponsored by INDOT and performed through the Joint Transportation Research Program at Purdue University, included more than 10 additional years of performance history and followed some projects through to the end of their service lives.

Indiana’s warranty program required the contractor to guarantee that the pavement would perform acceptably in terms of ride quality (as measured by the International Roughness Index, IRI), rut depth, longitudinal cracking and friction. Threshold limits have been established for these factors by statistically analyzing INDOT’s Pavement Management System (PMS) database. The thresholds were set so that at the end of the five-year warranty period, the pavement would be in such a condition that it would be expected to perform for the remaining 10 years of the 15-year design life. While other distresses could be considered, it was felt that ride quality would capture the effects of many of these distresses and would be more objectively and efficiently measured (using automated equipment). Annual surveys were conducted to monitor the performance.

Better with age

The objectives of this latest study of warranted asphalt pavements included re-evaluating and quantifying the performance of asphalt pavements built under warranty specifications and determining if there are compelling arguments to begin using asphalt pavement warranties again. Two approaches were employed to explore the long-term performance of the warranted pavements. In one, the research team re-evaluated the performance and costs of five pairs of projects that had been evaluated in an earlier study. In 2004, a different Purdue University research team compared five warranty projects to comparable non-warranted projects constructed in the same year with similar designs and traffic levels. At the time of that study, only three to five years of performance data were available for the pairwise comparisons.

In contrast, the recent study includes up to 17 years of performance data and captures the full service lives of most of the pavement sections. One warranted project is still in service after 16 years, so its ultimate service life is not yet known; all of the other sections are out of service. For these pairs of projects, the non-warranted pavement sections had service lives of 10-14 years, estimated by years from the original contract award date to the award of subsequent construction work (according to district information or the contract history database). The five warranted pavement sections lasted from 12-17 years. Overall, the warranted pavements outlasted the similar conventional pavements by one to seven years.

In addition to lasting longer, the warranted pavements performed better than the conventional sections. The IRI of the warranted pavements was 12% to 40% lower than the non-warranted pavements in four of the five comparisons, indicating they were smoother throughout their service lives. In the fifth pair, the average IRI was similar for both types of contracts. The rut depths on all of the pavements were quite low (less than 0.25 in.), but the rut depths on three of the warranted pavements were 13% to 45% lower than the conventional contracts. For the other two pairs, the non-warranted pavements had rut depths 9% and 13% lower than the comparison warranty projects, respectively. The overall friction numbers (FN at 40 mph) were higher for the warranty projects than the non-warranty projects at all ages.

The costs of the asphalt-related bid items for each pair of projects also were compared on a dollar-per-ton basis. In terms of initial costs, the warranted pavements were, respectively, 1%, 12% and 25% higher than the conventional sections for the three projects constructed in 1996 and 1997. In the other two comparisons, however, the initial costs were nearly identical for the pair constructed in 1998 and 4% lower for the warranted pavement in the pair built in 1999. This may suggest that contractors were initially leery of warranties and bid conservatively, but they gained confidence with a little experience. When the actual service lives were considered, the amortized cost (price per ton per year) was 12% to 30% lower for the warranted pavements in all cases.

All with similarities

While the five pairwise comparisons of warranted-versus-non-warranted projects painted a very favorable picture of the performance and cost effectiveness of warranted asphalt pavements, the findings could have been biased by the selection of the non-warranted companion project. For example, if the comparison section failed early because of an unexpected increase in traffic, that would skew the results in favor of the warranty project. So, in the second study approach, the available IRI and rut depth data for all 10 warranted pavements were compared to the PMS data for a much broader range of conventional projects. In all, 116 non-warranted interstate projects were selected to be as similar to the warranted pavements as possible by including similar work types and traffic levels with the same age distribution. The ages of both the warranted and conventional pavements ranged from five to 15 years with an average of 11 years. Friction data for all of the pavement sections was pulled from the friction inventory. The data for all the studied pavements was collected and analyzed in 0.1-mile segments.

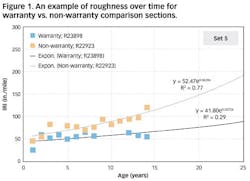

This broad comparison revealed that, in general, the warranted asphalt pavements were smoother (had lower IRI values) than the non-warranted asphalt pavements. The average IRI values for the warranted and non-warranted asphalt pavement sections were 56.9 in./mile and 75.1 in./mile. Statistical analysis shows that the warranted pavement segments were significantly smoother than the conventional segments at all ages; the IRI values were improved approximately 24% by implementation of asphalt pavement warranties. In addition, the variability in the smoothness of the warranted pavements was about 37% lower for the warranted segments.

The rut depths on all of the studied pavements were quite low, less than the 0.25-in. warranty threshold. Overall, however, the warranted asphalt pavements did have slightly lower rut depths than the non-warranted asphalt pavements; an average of 0.08 in. for the warranted asphalt pavements versus 0.09 in. for the non-warranted pavements, or a reduction of about 7%.

The average friction numbers of the warranted and non-warranted pavements were 48.43 and 40.23, respectively, which is a statistically significant difference. As with IRI, the friction data also was less variable on the warranty projects.

Deterioration curves showing the changes in IRI, rut depth and friction over time suggest that the non-warranted pavement sections were deteriorating faster than the warranted sections. If the warranty threshold limits for these parameters were applied to all of the 0.1-mile segments, significantly more stretches of conventional contracts would require remediation compared to the warranted segments, indicating they also would have higher maintenance costs.

Ready for more

This research showed that the asphalt pavements constructed in Indiana under warranty provisions lasted longer and performed better than similar pavements constructed under conventional specifications. The warranted pavements provided a smoother ride, less rutting and higher friction. Those pavements also were more consistent over their length and appeared to be deteriorating at a slower pace. Although the warranted pavements were somewhat more expensive in terms of initial costs per ton of mix, when the increased service lives were considered, the warranted pavements were substantially more cost effective than non-warranted pavements.

These research findings have only been available for a short time, but INDOT is actively exploring options for reinstating an asphalt warranty program at the current time. The details and extent of the program have yet to be established, but will likely rely on smoothness as an overall performance indicator. For Indiana, these research results offer compelling evidence that asphalt pavement warranties are effective tools for improving the performance of asphalt pavements, insuring against premature failures and extending service lives in a cost-effective manner over the long term.

Further details on this research can be found at: http://dx.doi.org/10.5703/1288284316339.

-------------

McDaniel is technical director of the North Central Superpave Center at Purdue University. Sadeghi is a graduate research assistant in the Lyles School of Civil Engineering at Purdue. Haddock is a professor of Civil Engineering at Purdue and director of the Indiana Local Technical Assistance Program.