When the National Center for Asphalt Technology (NCAT) started its 2012 research cycle, the famed Pavement Test Track was not the only home for the center’s cutting-edge asphalt-pavement research. As part of NCAT’s Preservation Group (PG) experiment, researchers tracked the effects of traffic and loading on different pavement-preservation treatments on a carefully prepared nearby county road.

Just as lessons learned from two full years of traffic on the NCAT Pavement Test Track will be highlighted at the 2015 Test Track Conference in March, lessons learned from the PG test sections on Lee County Road 159 (LR 159) will help quantify the life-extending benefits of pavement preservation.

Star treatments

In recent years, state DOTs have faced the pressures of preserving existing infrastructure with diminishing resources. In response, agencies are recognizing the need to apply traditional and non-traditional preservation treatments early in the pavement’s life cycle. However, there is insufficient life-cycle performance data necessary to reliably identify which treatment is the best investment, based on existing distresses.

The performance of a preservation treatment is dependent on the existing condition of the pavement, so while a given treatment may perform well when placed on a good road, the same treatment placed on a bad road may perform poorly. Existing estimates of expected life extension are too broad, making it difficult for agencies to identify realistic values for use in their pavement-management systems and to make objective decisions regarding treatment selection and application.

Recognizing this limitation could be overcome by linking performance expectations to pretreatment condition, researchers at NCAT added pavement preservation to its plan for the 2012 research cycle.

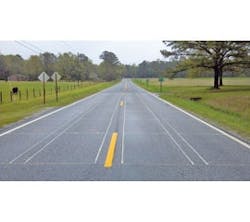

LR 159 is a dead-end roadway in nearby Opelika, Ala. The unique traffic patterns on the 5.5-in. flexible pavement—primarily trucks headed to and from a Martin Marietta quarry and an East Alabama Paving Co. asphalt plant—made LR 159 an ideal candidate for the test site. Although the traffic volumes are very low on this two-lane road, a data-sharing agreement with the asphalt plant and quarry enabled researchers to characterize the truck traffic in terms of equivalent single-axle loads.

The primary objective of this research is to develop independent, life-extending benefit curves for the various preservation treatments by documenting the time and traffic to return to pre-treatment condition. The road sections ranged in condition from good to poor, and measurements were recorded in terms of roughness, rutting, cracking, macrotexture and deflection prior to treatment placement to characterize pre-treatment condition.

Working with industry professionals, a consensus experiment was developed and a final layout of treatments was approved by all eight PG sponsors—state departments of transportation for Alabama, Mississippi, Missouri, North Carolina, Oklahoma, South Carolina, and Tennessee, along with FP2 (formerly known as the Foundation for Pavement Preservation).

The half-mile section of roadway was subdivided into 25 100-ft sections. Of the 25 sections, two were left as untreated control sections with the remaining sections receiving a treatment or combination of treatments. Treatments on the remaining 23 sections were placed in the summer of 2012. The control sections enable the calculation of the rate of deterioration, and as such, a means of quantifying the improvement in condition due to a preservation treatment relative to a “do-nothing” scenario.

A wide-range of treatments and combination of treatments were placed including various types of chip seals, as well as chip seals placed in single, double and triple layers; single- and double-layer microsurfacing; crack sealing; 100% foamed recycle inlay; and Thinlay thin asphalt overlays.

The thin asphalt overlays were placed at 0.75 in. Of the eight thin asphalt overlays, one ultra-thin bonded wearing course was placed and seven 4.75-mm nominal maximum aggregate size (NMAS) mixes were placed. The seven 4.75-mm NMAS mixes included an unmodified virgin mix and variations of this mix, including mixes with modified binder, highly modified binder, reclaimed asphalt pavement (RAP), and post-consumer recycled asphalt shingles (RAS). More information on the various treatments used on LR 159 can be found at www.pavetrack.com.

Pavement distress measurements were captured on a weekly basis. Each 100-ft, two-lane section was further subdivided into 40 5-ft by 10-ft subsections. These 40 subsections define the life-extending benefit curve, as the time and traffic to return to pre-treatment condition in each subsection are used to develop the curve. Therefore, it is necessary for all 40 subsections to eventually reach pre-treatment condition.

In addition to distress measurements, other measurements were made to quantify benefits of pavement preservation that are not visible at the surface of the pavement. For example, moisture probes embedded in each section captured the subgrade moisture content. Treated sections showed lower moisture contents in wetter months relative to the untreated control sections. In addition, falling weight deflectometer (FWD) testing was conducted on a monthly basis.

Although the performance of a preservation treatment is characterized by all of the pavement distresses, cracking is one of the more obvious and visible distress measurements. A threshold of 20% of the total lane area is a common threshold used for cracking. As shown in Figure 1, while some cracking (shown as the average total lane area cracked) was evident in most of the sections, only one section met this 20% threshold. As expected, the more robust treatments showed a slower rate of crack development and progression.

After more than two years of year-round traffic, the recurrence of some pre-treatment distresses were evident. Measurements of rutting, roughness, macrotexture and cracking along with subgrade moisture content and deflection measurements continued to be made on a regular basis until the end of the 2012 research cycle in March 2015. For those sections that returned to pre-treatment condition, objective life-extending benefit curves were developed and are being presented at the Test Track Conference in early March 2015, along with other findings from the PG study and 2012 research cycle experiments on the Pavement Test Track.

Continue and expand

To meet the objectives of the PG study, a full return to pre-treatment condition is necessary. NCAT researchers are planning for the continuation of the experiment through the 2015 cycle as the PG 15 study to capture when the test sections return to full pre-treatment conditions.

In addition to the continuation of the existing study, the PG 15 study also includes expansion of pavement-preservation treatment tests in other climates through a developing partnership between the MnROAD Minnesota Road Research Facility and NCAT. In this collaborative effort, the needs of both northern and southern climates can be addressed with a single project.

NCAT and MnROAD are currently identifying off-site locations on existing routes to conduct pavement preservation research to expand the existing PG study to two climates and higher volume traffic. As part of this expansion, a possible higher volume route in Alabama has been identified for placement of treatments mirroring those placed on LR 159 with the possibility for also considering additional treatments.

Agencies interested in learning more about the partnership or having a voice in the design of the PG 15 study should contact Dr. Buzz Powell, P.E., manager of the NCAT Pavement Test Track, at [email protected]. AT