Residents of Arlington, Va., recently celebrated the completion of the long-planned Rte. 27/244 Interchange Modification Project, a major infrastructure improvement set in a historic neighborhood near the Pentagon.

The $48.5 million project included design and construction of the new Freedmans Village Bridge, replacing the deteriorated Washington Boulevard (Rte. 27) Bridge over Columbia Pike (Rte. 244).

The original single-span concrete arch bridge was constructed in 1942 by the U.S. War Department as part of the extensive Pentagon Roadway Network. Rated structurally deficient, the bridge suffered from deteriorating concrete, corrosion of the reinforcing steel and heavy chloride contamination, as well as years of increasing traffic loads. According to Virginia Department of Transportation (VDOT) statistics, the bridge had been carrying 80,000 vehicles a day over Columbia Pike, with heavy use by commuters.

In 2010, VDOT selected the design-build team of Shirley Contracting Co. LLC and the consulting firm of Dewberry to design and construct a new bridge and to reconfigure the existing interchange. The team worked closely with VDOT, the Federal Highway Administration (FHWA) and Arlington County, as well as a highly engaged citizens’ task force that contributed ideas and feedback regarding the structure’s architectural and aesthetic treatments, mobility and access issues and maintenance of traffic concerns. Project objectives included improved operations and safety, the promotion of multimodal travel and preservation of access to local neighborhoods.

Construction began in the spring of 2012. The existing bridge was replaced with two side-by-side bridges carrying four 12-ft travel lanes, an auxiliary lane between ramps, widened shoulders and a light well separating the northbound and southbound lanes of Washington Boulevard. The interchange was reconfigured by eliminating one under-utilized ramp and realigning two ramps. Safety and operations on Columbia Pike were enhanced by relocating and replacing traffic signals, constructing a raised median and turn bays and providing a 10-ft shared pedestrian and bike path on the north side as well as an 8-ft sidewalk on the south side. Clearance under the bridge was increased to 16 ft 8 in. to maximize future multimodal opportunities.

Engineering challenges

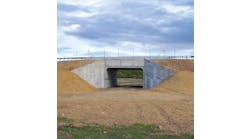

An existing 10-ft by 7.5-ft box culvert that conveyed Long Branch, a major stream, through the center of the interchange was replaced with a double-cell, 10-ft x 10-ft box culvert. The new culvert is aligned beneath the new bridge with the barrels of the box separated so that bridge foundation elements could be installed between the barrels. This approach maintained structural independence between the design elements and optimized the culvert length while eliminating the need to tunnel large-diameter pipes under Washington Boulevard. This also minimized impact to the Long Branch floodplain. At the outlet of the box, the alignment was kinked to allow flow to enter the natural stream channel in a better alignment. The new culvert design has reduced erosion and flooding that had long been a maintenance concern for VDOT, Arlington County and adjacent homeowners.

Another challenge involved the avoidance of existing utilities. The interchange is located in an older, dense area of Arlington, with a significant amount of utilities—many of which have been “snaked” into place at different times by different utility owners. The presence of these utilities complicated the installation of drainage pipes, culverts, the noise barrier, water and sewer facilities (installed to improve the function of existing facilities), and traffic-signal elements. During design, the team completed a large number of test pits to confirm existing utility locations and elevations. Construction of major project elements, including the bridge foundations, the box culvert and utility relocations, were phased to ensure existing utilities remained operational without impact to local residences and businesses. Temporary shoring and suspension solutions for existing utilities were also utilized to allow permanent relocations to continue simultaneously with drainage, bridge and roadway construction elements.

Poor soil conditions and Potomac clay layers presented a challenge throughout the site, introducing global stability, slope stability and settlement concerns. To address these geotechnical challenges, steel piles were installed in critical slope areas, including in front of a noise barrier, adjacent to a retaining wall, and near the inlet of a box culvert. Lightweight fill also was utilized at the bridge abutments to reduce long-term settlement concerns.

The design-build team had a choice to use cast-in-place or precast concrete elements for the bridge abutments and retaining walls. Precast was selected for several reasons, including speed of construction and the need to work efficiently within a tight construction area due to the surrounding traffic. The aesthetic treatments for the walls also would have required intricate forming details, and precast elements provided a cleaner, more consistent finish for the architectural details while ensuring that the desired aesthetics would be met through the shop-drawing process.

The abutments were constructed with steel friction piles driven with a diesel hammer to carry the bridge loading. The pile cap and abutment seat were then cast in place on top of the driven piles. The abutment walls were precast MSE walls with metal straps and engineered backfill. The walls were erected after the piles were driven, and straps and backfill were placed around the foundation piles.

The girders were 63-in. plate girders with the exception of the fascia girders, which were haunched on the ends. The haunched girders ranged from 99 in. on the ends to 63 in. in the middle, and included a two-tone paint scheme that mimicked the arched look of the original concrete arch bridge.

The concrete mix designs and volume consisted of the following, with cure times of generally four to seven days prior to proceeding with construction:

- A3 Drilled Shafts—336.5 cu yd

- A3 General—1,588.5 cu yd

- A4 General—1,657.5 cu yd

- A4 Bridge Deck—236 cu yd

- A4 Modified (LP)—1,322 cu yd

- A4.5 General—154 cu yd

- A4.5 Bridge Deck—360 cu yd

- Flowable Fill—613.5 cu yd

- Bridge Deck Concrete—596 cu yd

- Box Culvert Concrete—2,108 cu yd

Crews perform box culvert formwork on the Freedmans Village Bridge. The new culvert is a 10-ft x 10-ft double cell.

Staging of construction

The sequencing of construction was critical to the success of the project, enabling the team to manage traffic while completely rebuilding and reconfiguring the interchange. The maintenance of traffic plan required construction of temporary detour roads, installation of a temporary signal for use on critical weekends, temporarily reconfiguring access to local neighborhoods, modifying an existing traffic signal to accommodate new turning movements, and careful sequencing of the work so that permanent construction could be completed in phases while accommodating all existing or temporary travel lanes.

The tight footprint of the project site complicated the challenge of maintaining traffic flow with more than 120,000 vehicles on a daily basis. The existing interchange was bounded to the north and east by a hotel and residential treatment facility, and to the south and west by residential communities. This tight footprint limited the ability to implement detours and roadway diversions to move traffic temporarily out of the footprint of the existing interchange. Instead, the project was constructed in phases through the implementation of eight stages of temporary traffic-control plans. At the outset of construction, a temporary detour road was constructed within the footprint of the interchange. This detour was employed on critical weekends to move Columbia Pike traffic out from under the existing bridge. Recognizing that traffic volumes and patterns were different on weekdays and weekends, several temporary traffic-control stages were separated into weekday and weekend configurations. Nighttime operations and temporary closures also were used to facilitate demolition of the existing bridge and erection of the new bridge girders.

Reconstruction of Washington Boulevard also was completed in phases, with the northbound bridge being completed first, following partial demolition of the existing bridge. The longer span of the new bridge and raised profile to provide added vertical clearance over Columbia Pike required temporary shoring adjacent to the existing roadway and bridge. Following completion, both directions of Washington Boulevard traffic were shifted onto the new northbound bridge to facilitate demolition of the remaining portion of the old bridge and construction of the southbound bridge.

Demolition of the bridge was a challenge in and of itself. The existing bridge consisted of a solid concrete arch structure, which, as previously noted, had to be demolished in phases to maintain traffic. In order to complete the phased bridge demolition, traffic on Columbia Pike was shifted to the temporary detour roadway, and demolition crews used a wire saw to cut through the bridge, which at points consisted of more than 6 ft of concrete with strengths as high as 19,000 psi. Bridge demolition began on a Friday night and continued uninterrupted through the weekend, with final cleanup and traffic switches occurring on Sunday evening. Traffic operations were restored to their original configurations prior to the Monday morning rush hour.

Following completion of the major roadway elements, a final stage of construction was used to install a noise barrier, complete pedestrian and bicycle facilities, add landscaping and complete final paving and pavement-marking operations.

Connecting the community

The replacement overpass is located near a historic area once known as Freedman’s Village, established by the federal government in 1863 as a community for newly freed and fugitive slaves. The village was set on the captured property of Confederate General Robert E. Lee’s Custis-Lee estate and included homes, schools, a hospital and vocational facilities where residents could learn skills as blacksmiths, wheelwrights, carpenters, shoemakers and tailors. The government closed the community in 1900, and today the property includes several residential neighborhoods as well as Arlington National Cemetery and the Pentagon.

In 2009, the Commonwealth Transportation Board designated the new bridge as the Freedmans Village Bridge. The bridge design incorporates features that reflect the historical significance of the area, including bronze medallions that depict the village’s headquarters building as well as an image of a mother and two children inspired by an artist’s rendering of the village that appeared in Harper’s Weekly in May 1864.

Aesthetic features also include:

- Decorative, memorial pylons in each corner;

- Haunched steel fascia girders with a two-tone paint scheme to mimic the arch structure of the former bridge;

- A relief pattern incorporated into the vertical outer surfaces of the bridge parapet to create shadows and visual interest;

- A concrete block pattern on retaining and abutment walls similar to Pentagon architecture;

- Recessed, arched panels on the abutment walls; and

- Color and anti-graffiti application to concrete surfaces.

The new northbound bridge opened in November 2013 and the southbound bridge opened in August 2015. On Sept. 10, 2015, VDOT hosted a dedication ceremony for the new Freedmans Village Bridge that was attended by several descendants of the freed slaves who once lived in the village, as well as local, state and federal representatives, members of the local community and the project team. “Today’s dedication ceremony celebrates the completion of a new bridge that connects a vibrant and busy travel area in northern Virginia, connects communities, and connects the present time with a rich, historical past in Arlington,” Virginia Gov. Terry McAuliffe stated at the dedication. “Community input and partnerships were critical to this project’s development, and resulted in adopting the best available design options, and most importantly, led to the naming of the bridge as the Freedmans Village Bridge. The bridge is a model for the commonwealth of how partnership and cooperation can produce positive results and critical improvements to our infrastructure.”