Bridge approaches are normally constructed with reinforced concrete slabs that connect the bridge deck to the adjacent paved roadway.

The approach slab is usually supported on one side by the bridge abutment and on the other side by the embankment. Their function is to provide a smooth and safe transition of vehicles from roadway pavements to bridge structures and vice versa.

However, complaints about the ride quality of bridge approach slabs still need to be resolved. The complaints usually involve a “bump” that motorists feel when they drive on or off bridges. This problem is commonly referred to as the bump at the end of the bridge, mainly resulting from the differential settlement of the concrete approach slab relative to the bridge deck. It poses a safety hazard as well as being disruptive to motorists. Field observations indicated that either faulting at the roadway pavement/approach slab joint (R/S joint) or a sudden change in the slope grade at the approach slab/bridge deck joint (S/D joint) (as shown in Figure 1) causes this bump.

A viable solution

The flexural rigidity (EI) of the approach slabs is increased through increasing both the slab thickness and the reinforcement ratio. Consequently, some embankment settlement will be allowed without decreasing the ride quality. As a result, the slab dead load and traffic live loads will be carried by the two ends of the slab rather than distributed over the length of the slab. Accordingly, the local soil pressures beneath the strip footing increase, resulting in an increase in the faulting deflection (δD in Figure 1).

Geosynthetics can be used to reinforce the soil beneath the footing, thereby increasing the soil’s bearing capacity, helping redistribute the load to a wider area, and hence reducing the footing’s settlement. Several research projects have been initiated over the past decade by the Louisiana Department of Transportation and Development (LADOTD) in response to this need.

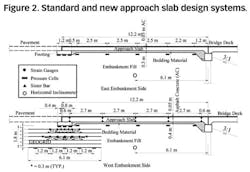

To validate the findings and the design recommendations developed in the previous research studies and to update the LADOTD’s design and construction guidelines for bridge approach slabs to mitigate the bridge end bump problem, the Bayou Courtableau Bridge, in St. Landry Parish near the town of Washington, was selected to demonstrate the new approach slab design system, which was installed on the west approach slab as shown in Figure 2. The state-owned Bayou Courtableau Bridge is a 295-ft-long steel stringer bridge built in 1936, which features a deck width of 24 ft and sees average daily traffic of approximately 4,500 vehicles.

The field performance, including deformation and internal stresses of the concrete slabs, contact stresses between the slab and the embankment, stress distributions within the reinforced soil foundation, and strain distributions along the geogrid were monitored for a period of 10 months following the installation.

Methodology

Two static load tests were conducted on both the west and east approach slabs of the bridge to evaluate their performance. The first one was conducted right before the bridge was opened to traffic, in October 2009. The second one was conducted 18 months later, in March 2011. Dead loads were placed on the slab by positioning a 20-ton large cone truck at strategic locations. International Roughness Index (IRI) measurements also were performed on both the east and west approach slabs. Figure 3 shows average continuous IRI roughness profiles of the left and right wheel paths of three repeat runs based on a 7.6-m base length (IRI 7.6 m) for both the eastbound and the westbound lanes. The two continuous IRI profiles shown

in Figure 3 clearly demonstrated better performance of the west approach slab with much lower IRI 7.6-m values, which is consistent with the visual observations made by researchers. The continuous IRI profiles also show that the maximum IRI 7.6-m values of the east approach slab were 8.4 m/km and 5.7 m/km for the westbound approach slab and eastbound leave slab, respectively, on March 24, 2011. These values increased to 11 m/km and 8.5 m/km on Jan. 15, 2014. Meanwhile, the maximum IRI 7.6-m values of the west approach slab remained almost constant, around 4.7 m/km, during the same period of time.

Crews conducted tests on the newly installed west approach of the bridge.

The takeaway

The west approach slab of the Bayou Courtableau Bridge, with the new design method, kept its contacts and supports from the embankment soil during the first static load test at the time the bridge was ready for traffic. However, during the second static load test 18 months later, the west approach slab had lost most of its supports from the embankment soil, but with less observed faulting at the R/S joint and with better rideability. The maximum measured contact pressure underneath the west approach slab decreased from 10.3 kPa (during first static test) to 3.4 kPa (during second static test), while at the same time the pressure increased underneath the footing mainly due to load transfer caused by increased slab rigidity. On the other hand, the east approach slab, with the traditional design method, showed slightly gradual loss of its contacts from the embankment soil starting from the bridge abutment side towards the pavement side. The maximum measured contact pressure underneath the east approach slab increased from 7.6 kPa (during first static test) to 9.7 kPa (during second static test).

The maximum measured strains in the geogrid due to the 20-ton truck loading were considerably lower than the 2% strain (max strain at 0.3 m below footing < 1%), which is the typical design strain value published by geosynthetic manufacturers.

The roughness profiles demonstrated better performance in the new approach slab system (west approach slab) compared to the traditional design method (east approach slab) with much lower IRI values. The maximum IRI 7.6 m of west approach slab remained almost constant (about 4.7 m/km)

from March 24, 2011, to Jan. 15, 2014, while the maximum IRI 7.6 m of the east approach slab increased significantly during this period (from 8.4 m/km and 5.7 m/km to 11 m/km and 8.5 m/km for westbound and eastbound).

The improved performance of the new (west) approach slab system as visually observed in the Bayou Courtableau Bridge demonstration project after a monitoring period of a year and half indicated to researchers that the application of the new approach design would have desired application to further distressed bridge approaches.