The longest jointless steel bridge in Virginia, the U.S. Rte. 340 South Fork Bridge spans the South Fork Shenandoah River and the Norfolk Southern Railroad on the northern outskirts of Front Royal, Va.

The new bridge replaces a deteriorating structure built back in the early 1940s, which surpassed its 50-year lifespan. Due to significant section losses in the steel deck truss elements, limitations were imposed for the use of the bridge to truck traffic during its final years of operation, hindering local commerce. The new structure is 95 ft wide and features six travel lanes as well as facilities for bicyclists and pedestrians.

“The old bridge had a substandard geometry which impacted and caused traffic congestion along the corridor where the northbound lane would back up traffic along the length of the bridge,” Eulogio Javier, P.E., assistant bridge engineer for the Virginia Department of Transportation’s (VDOT) Staunton District, told Roads & Bridges. “The project involved upgrading the bridge geometry to bring it up to current geometric standards, and reconfiguring the intersection of Rte. 340, 55 and 522.”

Though bridge design by public agency staff is generally less common, the Structure & Bridge office of the VDOT Staunton District used in-house resources to design the South Fork bridge. “This particular project presented an ideal opportunity for our engineers to gain valuable design experience,” Javier said. The design team at VDOT evaluated multiple replacement configurations to replace the deteriorated bridge and alleviate traffic congestion along the corridor served by the structure. The team settled on an eight-span concept which includes six of its spans having lengths of 260 ft and seven uniquely designed piers, some as high as 75 ft, founded on either bedrock, driven steel piles, pre-bored piles, or optional drilled shaft foundations.

As the project involved reconfiguring the Rte. 340 and 55 intersection, the design team considered non-traditional intersection treatments. In the end, the approach known as a quadrant roadway intersection was selected, which removes left turns from the main intersection and directs vehicles needing to turn left to a connecting section of roadway that forms a quarter loop between the two main roads.

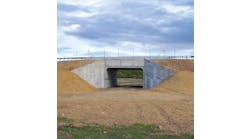

Some major constraints for this bridge included an existing Norfolk Southern Railroad track which passed beneath the end span on the south side of the bridge. The vertical and horizontal clearances limited this span length to a range of 160 ft. The bridge also had to be built in multiple stages to maintain four traffic lanes in two directions and a sidewalk at all times.

The design also incorporated the Virginia Abutment, which is part of a recently developed design method at VDOT aimed at eliminating expansion joints in an effort to reduce bridge lifecycle costs. This method has been used on more than a dozen long bridges in the state.

Project: U.S. 340 over South Fork Shenandoah River

Location: Front Royal, Va.

Owner: Virginia DOT

Designer: Virginia DOT—Staunton District

Contractor: Wagman Heavy Civil Inc.

Cost: $49.8 million

Length: 1,910 ft

Completion Date: Dec. 22, 2017