In the asphalt paving industry, the cost of building asphalt pavements continues to rise.

As a result, the asphalt industry continues to find ways to stretch road-building dollars while attempting to maintain the quality of asphalt mixes.

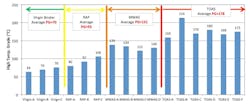

Figure 1. Recycled binders from both RAP and RAS are often severly aged and substantially stiffer than virgin binders.

One of the ways is to expand the use of recycled materials. Both reclaimed asphalt pavements (RAP) and recycled asphalt shingles (RAS) have been increasingly used in asphalt mixes to replace virgin asphalt and aggregate materials in order to reduce mix costs. In Texas, over 1 million tons of RAP and 150,000 tons of RAS were used in asphalt mixes in 2014. The trend is to use more and more recycled materials in asphalt mixes, notably hot-mix asphalt (HMA), because it not only reduces the construction cost and improves the rutting resistance of asphalt mixes, but it also improves sustainability by aiding in the reduction of greenhouse-gas emissions and contributions to landfills.

However, recycled binders from both RAP and RAS are often severely aged and substantially stiffer than the virgin binders, as shown in terms of penetration grade (PG) in Figure 1.

As the percentage of recycled materials increases in asphalt mixes, the ratio of the aged binder to the total binder increases, resulting in a stiffer mix that often has a lower resistance to cracking, which is one of the major concerns with RAP/RAS mixes. It is critical to establish a mix design method to systematically address the premature cracking problem so that these recycled materials can be effectively and economically used in building better roads.

Well-balanced

The process of designing asphalt mixtures in the laboratory entails achieving a balance of both rutting resistance and cracking resistance. In the past, most widely used mixes were virgin mixes successfully designed with volumetric mix design criteria plus a rutting test. Nowadays, asphalt mix designs are becoming more and more complex with the increasing uses of recycled materials (RAP/RAS), recycling agents, binder additives/modifiers (such as recycled engine oil bottom) and multiple warm-mix asphalt (WMA) technologies. These changes have altered the performance of mixtures both positively and negatively so that the existing mix design method (the volumetric mix design plus a rutting test) is not sufficient for evaluating the potential behavior of asphalt mixtures, especially with regard to mix-cracking behavior. A new, balanced mix design system is warranted.

Figure 2. An asphalt overlay design system was developed to determine the OT cycles required.

The balanced mix design system includes three major components: compaction and volumetric criteria (such as air voids), a rutting test and associated criteria, and a cracking test and associated criteria, as shown in Table 1.

A Superpave gyratory compactor (or Texas gyratory compactor) can be used to evaluate volumetric property. The Hamburg wheel track test has been used in Texas to control rutting and moisture damage of asphalt mixes for the last two decades, and associated rutting criteria also were well established.

To address the most critical issue of RAP/RAS mixes—cracking—the Texas Overlay test (OT) has been successfully employed for the last five years. The OT cycles from the OT test correlate well with cracking performance in the field. The higher the OT cycles, the better the cracking performance of the mix in the field. Field performance of many test sections in Texas clearly indicated that the OT criteria for mix design depends on the service condition of the mix, including traffic, climate, pavement structure and existing pavement conditions for asphalt overlays.

Recently, an asphalt overlay design system (Figure 2) was developed to determine the OT cycles needed to meet the cracking performance requirement. The balanced mix design system has been used for designing many field test sections in Texas.

Four scored

Four RAP test sections were constructed on I-40 near Amarillo, Texas, on Aug. 11, 2009. The existing pavement had a total of 8 in. of existing HMA with severe thermal-related transverse cracking that extended the full depth of the HMA (Figure 3). The reason for choosing these four sections was to permit the rapid determination of field performance of sections designed by both the current mix design method and the balanced mix design method. Table 2 lists all mix design information of these four test sections, including optimum asphalt content (OAC), Hamburg wheel tracking test (HWTT) and OT.

The pavement design called for a 4-in. milling and a 4-in. overlay section. Amarillo’s climate is temperate semi-arid, characterized by numerous freeze-thaw cycles and occasional blizzards during the winter season. Average daily high temperatures of Amarillo range from 48°F in January to 92°F in July. Furthermore, the traffic on I-40 is extremely heavy with over 50% heavy-loaded trucks in the traffic stream. The cold weather, heavy traffic loading and severe existing pavement cracking made this a good case study to rapidly evaluate the impact of different RAP layers on pavement performance, especially reflective cracking.

Since the construction on Aug. 11, 2009, field surveys were conducted on April 22, 2010; Sept. 8, 2010; April 5, 2011; Dec. 15, 2011; May 30, 2012; Dec. 19, 2012; and May 16, 2013. No rutting was observed, but reflective cracking was observed on these four test sections on the third survey. Detailed reflective cracking development for each section is shown in Figure 4. Note that prior to placing the overlay, the number of pre-existing cracks in each section was documented and mapped. The reflective cracking rate was therefore defined as the ratio of the number of reflective cracks to the original number of cracks before the 4-in. overlay.

It is clear that the higher the lab OT cycles of the RAP mix, the lower the reflective cracking rate, which further validates the effectiveness of OT for reflective cracking. It also clearly indicates that the 35% RAP test section with 200 OT cycles performed the best among the four sections. Note that the OT cycles listed in Table 2 were measured from plant mixes which were actually paved in the field.

The overall conclusion from these four sections is that high RAP mix can have better performance than the virgin mix, but it must be well-designed, following appropriate mix design methods.

Figure 3. This picture shows existing pavement conditions of I-40 after milling.

Ready to roll

The use of RAP and RAS in asphalt mixes is the right thing to do. It could be a win-win scenario for everyone: the asphalt industry, state departments of transportation and the road users, because the RAP/RAS mixes can have similar or even better performance than virgin mixes if they are well designed, balancing both rutting/moisture damage and cracking requirements.

Figure 4. Field performance of four RAP test sections on I-40.

A balanced mix design system including volumetric, rutting/moisture and cracking requirements has been developed in Texas for designers to develop durable asphalt mixes containing RAP, RAS and a recycling agent (or rejuvenators). This balanced mix design system has been successfully designed for many field test sections in Texas, and it is ready to be implemented as a routine mix design procedure. R&B