The Washington Department of Transportation (WSDOT) is leading the effort to develop the world’s largest concrete pavement preservation experiment.

This experiment, based upon the Long Term Pavement Performance (LTPP) project on concrete pavements termed SPS-2, will extend the performance data collected by the SPS-2 experiment and analyze how the respective preservation treatments will impact the deterioration rates of the different test sections. This will provide a cradle-to-grave analysis of the SPS-2 test sections and the respective preservation treatments used.

To accomplish this, WSDOT has developed a pooled-fund effort which now includes seven state departments of transportation—Arizona, California, Colorado, Georgia, Kansas, North Carolina and Washington. These states have pooled their funding resources to develop a shared research effort.

Concrete pavement preservation is typically considered to consist of diamond grinding, partial-depth repair, full-depth repair, joint resealing, dowel bar retrofit, longitudinal crack stitching, and slab jacking and stabilization.

The project has been scoped in several phases with the first phase contract being awarded to Nichols Consulting Engineers of Reno, Nev. The first phase was intended to provide a review of the various SPS-2 test sections to establish which sections are available to conduct a preservation experiment, and to develop a statistical experiment based on the remaining sections. Discussions also are underway on extending the Phase 1 effort to conduct an analysis that would compare the predicted performance to the actual performance to help in selecting sections for preservation treatments.

General and specific

The LTPP, which began in 1987, was initially designed as a comprehensive 20-year study of in-service pavements. This effort resulted in the development of a series of rigorous long-term field experiments monitoring more than 2,400 asphalt and concrete pavement test sections across the U.S. and Canada.

The LTPP program consisted of two approaches: General Pavement Studies (GPS) and Specific Pavement Studies (SPS). The GPS efforts used existing roadway sections of various ages, designs and climates selected through a controlled experimental design to determine the effects of specific features on performance. Since this experiment used existing roadway sections, it was established to provide research results in the short term.

The SPS experiment consisted of nine experiments, designated as SPS-1 through SPS-9, that addressed the effects of structural factors, maintenance treatments, rehabilitation alternatives, environmental effects, and asphalt concrete mixture type on pavement performance. The SPS approach required construction of standard test sections which enabled testing of the original materials, and monitoring and documenting the construction procedures. This approach also enabled a cradle-to-grave analysis of the projects, providing a more rigorous experiment. Most of the SPS experiments were designed as long-term experiments. The SPS-2 experiment was designated as the Strategic Study of Structural Factors for Rigid Pavements.

The standard SPS-2 experiment consists of 12 LTPP test sections constructed in each of 14 states. The numbers within each state represent the year the SPS-2 test sections were constructed in the respective state. As indicated, the projects now range in age from 16 to 24 years.

The SPS-2 experiment was designed to evaluate the relative influence and long-term effectiveness of five design features and three site factors. The five design factors comprise:

- Concrete thickness (8 in. and 11 in.);

- Base type (lean concrete, dense-graded aggregate, permeable bituminous treated);

- Concrete flexural strength (550 psi and 900 psi at 14 days);

- Lane width (12 ft and 14 ft); and

- Drainage (with and without edge drains).

The three site factors considered in the experimental design are indicated below:

- Climate—temperature and freeze/no freeze;

- Climate—precipitation; and

- Subgrade—fine-grained and coarse-grained soils.

Traffic was not part of the experimental design, but was treated as a covariant with the only requirement being that candidate projects achieve a minimum traffic level of 200,000 ESALs/year.

Since fixed structural designs were used for all traffic levels and site conditions, the design life of each SPS-2 test section may be different within a given project and among the 14 projects. So it should be anticipated that preservation treatments will occur at different times for different sections.

What to consider

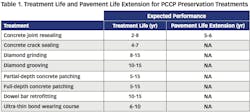

Life extension of concrete pavement preservation treatments: The most recent national study of concrete pavement preservation was conducted by the SHRP-2 program in 2011. Table 1 is an excerpt from that report and indicates the expected pavement life extension for each of the listed concrete preservation strategies. As indicated, insufficient information exists to quantify actual life extension. It is evident that there is a compelling need to determine actual pavement life extension results for each of the treatments indicated in Table 1 so that cost-effective solutions can be selected.

Development of PMS triggers for concrete preservation: The rigid subcommittee of the FHWA ETG on Pavement Preservation previously completed a survey of states’ practices regarding the use of pavement management in determining when and how to conduct preservation of concrete pavements. This survey indicated that approximately 60% of participating states use PMS triggers for this process. However, it was noted that few, if any, other states use the same procedures, suggesting that additional research is necessary to define the best techniques for defining the intervention thresholds, appropriate measurements and determining strategy effectiveness.

Improved ride quality: If it is determined that the ride quality of any of the sections has exceeded a reasonable level, it is possible to determine the amount of improvement resulting from diamond grinding through tools such as the FHWA ProVAL software. Coupled with the analysis capability of the MEPDG, it is now possible to determine the predicted pavement life extension resulting through different levels of smoothness improvement. This then provides a vehicle for optimizing the diamond-grinding process by balancing cost to attain the smoothness against the resulting benefit or life extension. Such an approach has not been previously possible and may, in the future, provide the incentives to conduct earlier interventions.

Sealant research: One of the unanswered questions regarding concrete pavement preservation is the effectiveness of joint sealing and resealing. Since these projects are 16 to 24 years of age, the effectiveness of the sealant and the need for resealing should be considered.

Changes in material properties over time: One of the attributes of concrete is that it continues to gain strength over time. This should be characterized prior to the placement of the preservation treatment to enhance the information available for the original SPS-2 experiment, as well as to benchmark conditions for the new preservation experiment.

Development of the best preservation techniques and materials: The SPS-2 projects provide a unique opportunity for a partnership between industry and agencies to gauge the performance of concrete pavements and their preservation techniques/materials that have been used across the country, and to verify which techniques are performing best. Based on this type of assessment, it may then be possible to foster development of improved products. This would allow a better opportunity for defining the best practices available today.

U.S. scanning tour of the SPS-2 performance: Since construction of the original experiment, there has been little or no opportunity for agencies to evaluate the performance of the various sites outside of their respective states. A valuable technology transfer function would be the ability to conduct a scanning tour of the largest ongoing concrete experiment in the nation. This could be an excellent agency-industry partnership and would represent a significant opportunity to bring home the early findings of the SPS-2 experiment first hand. That is, to tell the story as to what is happening, and to evaluate how the pavement performed at each location and why.

Evaluation of non-destructive test devices: Non-destructive test equipment has been refined since the construction of the SPS-2 experiment. For example, it is now readily possible to identify the location and tolerances of the dowel bars and tie bars in the sections. This will allow more comprehensive evaluation of pavement performance instead of just assuming they are located per plans. Similarly, ground-penetrating radar and other technologies have advanced so as to be more accurate and reliable. A unique opportunity exists to characterize the pavement design features from a continuous standpoint as opposed to discrete test locations. This should provide advantages in analysis.

The LTPP project resulted in a series of long-term field experiments monitoring over 2,400 asphalt and concrete pavement test sections across the U.S. and Canada.

Ready for questions

The SPS-2 pooled-fund pavement preservation experiment is attempting to leverage the existing $10 to $20 million investment expended on the construction, testing and evaluation of the world’s largest ongoing concrete research project. The preservation effort is intended to develop a cradle-to-grave analysis of the sections that includes the original construction life as well as the pavement life extension resulting from the preservation techniques. This approach has never been available in previous research due to the cost and time frames necessary to execute such an effort.

Coupling the two experiments together and utilizing technology advancements in non-destructive testing should provide a unique approach to answering the age-old question as to what are the appropriate performance measures, what are the appropriate intervention times and what is the pavement life extension resulting from application of concrete pavement preservation strategies.