Relocating traffic, working in a confined site and adhering to strict environmental regulations are all significant challenges to completing a project. Despite its myriad complications, the 10-span arch bridge over the Fox River in the western suburbs of Chicago remains on schedule and on budget.

The project, which involves rebuilding and widening a 3.4-mile section of interstate in the far western suburbs of Chicago from two lanes to three lanes between the Aurora Toll Plaza and Orchard Road, boasts the new Fox River Bridge, which will replicate the appearance of the 50-year-old existing bridge and carry three lanes of eastbound traffic with full shoulders when it is completed later this year. The existing structure will be rebuilt in 2009 using the same design to accommodate three lanes of westbound traffic.

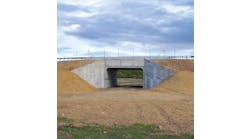

These two bridges are the only arched bridges in the Illinois Tollway system. The Fox River Bridge project team has faced numerous obstacles. They have had to work in a confined site both above and below the new bridge, coordinating the transportation of arch segments and performing work in a river that experienced abnormal flood levels. The Tollway also had to make sure environmental regulations were strictly enforced so that construction activities would have minimal impact on the river.

The Fox River, which begins 140 miles upstream in Wisconsin, consists of 1,680 sq miles of tributary area upstream of the project site.

“This aspect of the project also included the input of a multitude of environmental agencies to ensure minimal impact to the river and its natural inhabitants, best practices for handling erosion control during construction and that the areas upstream of the bridge were not flooded by the temporary work platforms in the river,” Paul Kovacs, chief engineer for the Illinois Tollway, told Roads & Bridges.

Under normal conditions, the river flows at approximately 500 to 700 cu ft per second; it was measured at more than 6,000 cu ft per second during spring construction.

Even before the river began reaching higher levels and flows, the project presented a complex set of challenges. The team had to maintain open channels while ensuring it could easily transport heavy equipment and materials. This meant building temporary access structures, including a temporary bridge, to deliver materials and perform work.

The project involved reconstructing portions of the highway and relocating a local road and intersection to accommodate industrial traffic along Rte. 25.