Developments in vehicle automation technology are accelerating at a breakneck pace, leaving transportation planners and regulatory agencies racing to catch up. Most mid-range and higher 2017 model automobiles and trucks come equipped with the key building blocks of vehicle automation and communication technologies: solid state radars, micro-video cameras and advanced software. These advancements allow for communication among vehicles using applications like adaptive cruise control, emergency braking and lane-departure warning.

While consumer cars have embraced these new technologies, it has taken the trucking industry far longer to integrate advancements in automation. However, Federal Motor Carrier Administration (FMCSA) Hours of Service (HOS) regulations that have been in effect since 2011, as well as safety concerns amplified by the growing truck driver shortage, is sparking the development of truck-specific automation technologies.

Truck platooning and its benefits

While it seems unlikely that completely autonomous trucks will be on U.S. roads in the next few years, developments in automation are making their way into the trucking industry in the form of truck platoons. This new technology involves a series of two or three wireless truck trains that follow a driver in a lead truck, using automated technology to communicate. Truck platoons could help address some of today’s major concerns in trucking.

FMCSA Hours of Service regulations and driver shortages:

Labor forecasters anticipate the current truck driver shortage will worsen over the next decade as the bulk of the labor force moves closer to retirement. The need for truck drivers is then amplified by FMCSA’s HOS regulations, which specify driving time limitations and defined rest periods. Truck platooning might alleviate these issues by limiting the number of hours a driver would need to operate the vehicle manually. In a version of this future truck train scenario, a “spare driver” could be resting in the sleeper cab for half of the trip and then take over driving the “pilot truck” for the second half of the trip, expediting a long-haul trip while complying with FMCSA Hours of Service regulations.

Safety:

In 2015 alone, 3,852 people died in large truck crashes. Truck platooning provides steady-state cruising operations with precise control of acceleration and breaking. Given these factors, an effective system could reduce the most common type of collision involving heavy trucks—end-to-end collisions—while also reducing the impact of human error, which the U.S. DOT has found to account for 90% of crashes involving heavy trucks.

Reduce congestion, fuel emissions and shipping costs:

Truck platoons have much shorter safe following distances than standard vehicles, which reduces wind resistance and increases the number of trucks that can fit on the road at high speeds, thereby increasing fuel efficiency and roadway capacity, respectively. Some projections estimate that corridors could support up to 50% more trucks if platooning is heavily supported, essentially the equivalent of adding a third lane. Additionally, truck platooning can reduce fuel emissions of up to 10% per platoon and, with widespread adoption, reduce overall shipping costs.

With these benefits in mind, experts anticipate that truck platoons that use manual steering with automatically controlled accelerating and braking will deploy on certain long-haul routes and in dedicated truck lanes in the 2020s.

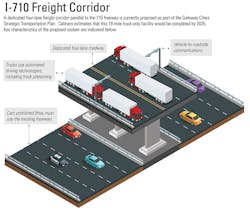

Figure 1. Caltrans uses findings from the truck platooning demonstration on I-580 to help inform this I-710 dedicated truck automation concept.

Demo in California

As part of the FHWA Exploratory Advanced Research Program, the California Department of Transportation (Caltrans), supported by UC Berkeley PATH, Volvo, Cambridge Systematics and LA Metro, deployed a successful truck platoon along I-580 between the towns of Dublin and Tracy in 2017. The truck platooning demo sought to conduct high-speed testing, examine platooning maneuvers, such as platoon splitting and joining, observe the impacts on fuel economy, and study fault detection.

The UC Berkeley PATH-led testing program, which included the demonstration on I-580 and a closed-track testing at a facility near Montreal, Canada, provided limited validation of the overall concept of three-truck platooning technologies. The results showed:

- Standard trailers and trucks can save 5% energy on average in a three-truck platoon;

- Aerodynamic trailers can increase energy savings by 12-14% compared to standard-trailer solo driving;

- The aerodynamic drag energy savings is not very sensitive to time gap values from 0.6 to 1.5 seconds (57 to 143 ft at 65 miles per hour);

- The third truck in the platoon saves the most energy, while the lead truck saves the least; and

- Further studies are needed to investigate the effects of shorter and longer gaps between trucks in a platoon.

This demo had added significance to the transportation agencies in California because it will help inform the design of the future I-710 dedicated truck lanes. The automation concept for the I-710 dedicated truck lanes is outlined in Figure 1 and may be built in the Los Angeles port region in the 2020s. These dedicated truck lanes will allow for connected truck technology to more efficiently move regional freight out of the ports of LA and Long Beach. As such, the demo focused on several areas to advance this goal, particularly vehicle-to-vehicle (V2V) communication technology.

Technology used in Caltrans truck platooning demo

This demo used V2V and Cooperative Adaptive Cruise Control (CACC) in-vehicle technologies. Through sensors, CACC enables vehicles to have and exchange information about all of the trucks in the platoon, not just the one immediately in front of it. This is done through communications of key parameters like position, velocity and acceleration.

The platoon was equipped with cooperative braking and accelerating, which meant the trucks could speed up, slow down or stop in tandem with the other trucks, which is one of the safety benefits of this technology. Figure 2 provides an overview of the truck platooning system architecture. In this diagram, the “J-Bus” refers to the truck’s information network architecture that connects to the system using a special interface computer designed by Volvo (the Volvo XPC). This interface provides the key basis for the platooning system computer (the PATH PC-104 QNX RTOS) to access the vehicle’s controls for acceleration and breaking. Additionally, the platoon uses Dedicated Short Range Communication (DSRC) V2V communications, which allows each truck’s platooning system to talk to each other—this is facilitated through the “WSU DSRC with Dual Antenna” that is mounted on each truck. Also, the radar/lidar sensors and video cameras required by the CACC to determine spacing and traffic conditions are furnished with connections to appropriate computers for processing. The test also included a driver display interface (Tablet DVI), a test system user interface (PATH Linux Laptop), a GPS antenna and, most important, an emergency switch to turn off the system.

Information & communication technology infrastructure

The current national framework for the connected vehicle environment envisions the use of 5.9 GHz DSRC, cellular (e.g. 5G, LTE), or other types of potential radio communication between vehicles and the surrounding infrastructure. While some of the anticipated applications for connected vehicle-instrumented corridors could conceivably utilize non-DSRC communication to realize functionality, DSRC is the only option that would have a specific impact to the local infrastructure.

DSRC was established by the U.S. DOT as a specifically allocated set of channels and frequencies for use in the anticipated connected vehicle world. It also is central to a continuing series of field evaluations and pilots being done by the U.S. DOT. Recent estimates indicate that 20% of vehicles in the U.S. will be equipped with some form of connected vehicle technology by the year 2025. U.S. DOT, supported by SAE, promotes and invests in test programs and guidance to develop common protocols for both V2V and vehicle-to-infrastructure (V2I) communications. In the coming years, it will be essential for the vehicle manufacturers to either adopt these protocols or come up with (in partnership with the public sector) an alternative set of accepted common protocols that can be used to facilitate transfer of V2I information to support connected vehicle applications.

For vehicles traveling on freeways and highways, onboard communications equipment should be integrated with application equipment and processors. Much of the enabling technology for the autonomous functions will reside in the individual vehicles and include a wide variety of original equipment manufacturer onboard vehicle systems. This onboard equipment and technology will communicate with a variety of operation centers and remotely situated application servers. The enabling architecture likely will utilize both cellular and DSRC communication.

Figure 2. An overview of the truck platooning system architecture used for the I-580 demonstration in California.

Technology-based deployment challenges

Technology is crucial in ensuring that truck platooning can happen now and advance in the future. For the near-term CACC-based truck platooning that does not involve autonomous trucks without drivers, the primary regulatory issue that must be addressed are state “anti-convoy” laws. Many states have anti-convoy laws that preclude truck platooning. In most cases, these laws were implemented between the 1960s and 1980s to aid state enforcement agencies in combatting unsafe truck convoys, where truck drivers attempted to convoy in closely spaced groups as a means to exceed speed limits and avoid citations.

California’s anti-caravanning law, enacted in the 1970s, requires a minimum spacing of 100 ft between vehicles, which is far larger than the amount of spacing recommended for platoons. For the demo in California, Caltrans and its project partners were able to attach language to the law that allowed the team to proceed with the test program and report back to the legislature with their findings.

What’s next

For future truck platooning concepts that involve autonomous/driverless vehicles to occur, both state regulations and federal regulations must be revised before such systems can operate across the nation. Test program legislation at the state level is a method that can support the development and testing of these technologies in the interim.

At the federal level, the Obama-era Federal Automated Vehicles Policy released by the U.S. DOT and the White House provides a high-level policy blueprint for government agencies and private sector industries to work together to advance technologies and develop more detailed regulations and rulemaking in the coming years.

It is hard to say with any certainty when completely autonomous vehicles and trucks will be introduced to U.S. roads. What is certain is that the technology developments that will impact future mobility and redefine how trucks operate are already underway.

The public and private sectors must work together to create policies around these technologies to help ensure they make positive impacts on road safety, goods movement and truck driver operations.