There were fingers showing in the marshy, swampy area in Staten Island, N.Y.

Any engineer would designate the scene for the Goethals Bridge Replacement Project as somewhat horrific. Located in a low-lying, wet and environmentally sensitive area, the New York side of the crossing offered design and construction challenges right from the get-go. The span connects Staten Island, N.Y., to Elizabeth, N.J., but the New Jersey side, with 12 lanes of the New Jersey Turnpike, four Conrail freight line tracks, an inactive historic rail trestle, additional local rail crossings and two local roads, was every bit as challenging as the swampy New York end.

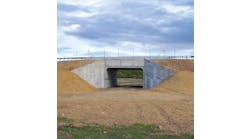

In order to get to where they needed to be on Staten Island, an access road had to be constructed—wide enough for construction equipment but small enough to honor permit requirements—down the center of the alignment between the eastbound and westbound structures. Stemming from this road were “fingers.” At each pier location, a finger was constructed perpendicular to the access road and was used for access to construct the piers, as well as locations for crane setups. The access road and fingers consisted mainly of unreinforced and reinforced soil and was pile-supported in the area adjacent to Old Place Creek.

Not all complications were known up front. It was discovered that a warehouse by Old Place Creek and in the footprint of the N.J. footing of the eastbound tower was contaminated with asbestos. The demolition pushed back the construction schedule.

The joint venture of Kiewit-Weeks-Marine and designer Parsons kicked into high gear. Originally the plan was to have a single tower support both eastbound and westbound. Parsons decided to build two separate bridges, each with a tower. However, when the demolition of the warehouse took longer than anticipated, Kiewit-Weeks-Marine asked Parsons to re-sequence the design and focus on the westbound structure instead, and an access trestle was constructed.

Because the site is just a few miles from Newark Liberty International Airport, maximum tower height was 272 ft, which drove unusually shallow cable angles. A unique anchor box shaped like a saddle allowed the cables to be stacked more tightly than a traditional anchor box, increasing the stay angles. It also allowed for the anchor boxes to be placed on the outside facing the towers, which allowed Parsons to keep the profiles for the towers slender.

“None of the steel fabricators would even bid on it until we printed a 3-D model,” Seth Condell, design manager for Parsons, told Roads & Bridges.

The access road and five-span aligned trestle, which also was used for access, will be used for future maintenance.

Project: Goethals Bridge Replacement Project

Location: Staten Island, N.Y., and Elizabeth, N.J.

Owner: Port Authority of NY & NJ

Designer: Parsons

Contractor: Kiewit-Weeks-Massman joint venture

Cost: $1.5 billion

Length: 7,300 ft

Completion Date: Dec. 31, 2018