Almost 100 years ago, in the fall of 1917, June McCarroll implemented an idea to designate roadway lanes by painting a mile-long white line down the center of a highway in California.

She campaigned for this idea to be employed statewide, and in 1924 the California Highway Commission agreed, authorizing 3,500 miles of lines to be painted. It did not take long before the idea was adopted worldwide.

Recently the Wisconsin Department of Transportation (WisDOT) took a pavement marking idea that many countries around the world have been using for many years, and incorporated it into the Zoo Interchange Reconstruction Project, the largest highway reconstruction project in the state: the use of orange pavement markings in the work zone.

Challenges of winter work zones

The Zoo Interchange (Zoo IC) is the highest volume interchange in Wisconsin with over 350,000 vehicles per day traversing the intersection of I-94 and I-41 on the west side of Milwaukee. The $1.7 billion reconstruction of the Zoo IC is a six-year project with work occurring year-round.

The frequent stage changes needed to maintain traffic (more than 100 in the last three years) cause numerous pavement markings and removals, which scar the pavement and make it difficult for drivers to maintain their lanes. Many times the scars left by removing markings leave white lines (polished surface on concrete or fractured white aggregate in asphalt) that resemble pavement marking lines, which confuses drivers. In addition to the scarred pavement, the area is heavily salted in the winter months during snow-removal operations. The salt residue masks white pavement markings and drivers cannot distinguish lane shifts, even on sunny dry days.

This situation caused significant safety issues in the winter of 2013-14. Drivers made hundreds of calls complaining that they could not see the white lane lines while driving through the work zone for bridge construction over the freeway. Area news outlets highlighted the issue in articles and TV reports which showed video of drivers who did not maintain their lanes while traversing lane shifts. When the pavement markings were difficult to recognize, drivers looked to other cues to maintain vehicle position, like joint lines or normal shoulder distance to a barrier wall. These efforts were counter-productive in lane shifts that crossed pavement joints and utilized the shoulder pavement due to a work zone on the opposite side of the freeway.

The result was that drivers unknowingly moved into adjacent lanes and caused many close calls with vehicles that were able to follow the work-zone lane alignments. Drivers requested that the lanes be remarked, but what was needed was contrast with the salt residue. Contrast markings (white on black) were considered, but this would involve another marking operation in the short time frame of overnight closures in cold conditions.

WisDOT operations staff captured compelling video from freeway traffic cameras which showed that drivers could not follow the lane shifts on a sunny dry day in February 2014. The white lane lines were almost invisible to the morning commuters due to the combination of low sun angle and the dried salt residue on the pavement. The video showed drivers in the right two lanes merging at a lane shift, while drivers in the left lane alternated between following the shift onto the shoulder and following the old joint lines. This caused queues several miles long, as if there was an unforeseen lane closure. At times there was 15-20 ft between vehicles in adjacent lanes, and both drivers were not sure who was in the correct position. Video from the same night showed that the lane lines could be seen with area street lighting and all vehicles maintained lane discipline while traversing the same lane shift.

The daytime video showed the yellow left-edge line which helped some of the drivers in the left lane to follow the shift. This video convinced project management that the issue was not a matter of refreshing the temporary white markings, but that they could not be seen in some of the winter conditions. If yellow could be seen, then perhaps another color could work well in winter. Hence, the orange color used for work-zone signs and barrels was considered for work-zone pavement markings.

Request to experiment

WisDOT had considered the use of orange markings as a way to distinguish the work-zone markings from the scars left from marking removals, but decided in the design phase that the problem was not worth the cost to implement a new pavement marking color. Since orange was not an existing pavement marking color in the Manual on Uniform Traffic Control Devices (MUCTD), a Request to Experiment (RTE) to the Federal Highway Administration (FHWA) would have been required. Once the winter conditions were actually experienced in the construction phase, the idea to use orange markings gained significant traction in the spring of 2014.

Many European countries, as well as Canada, have been using orange markings successfully in work zones for many years, regardless of weather. (In Switzerland the old markings are not even removed!) Drivers there know once you see the orange markings you are to ignore the old white (and yellow) markings. Canada only uses orange on barrier-separated freeways; WisDOT used their example and justification in its RTE to FHWA.

FHWA was contacted to see if work-zone-specific pavement markings had been tested under a previous experiment. They indicated that it had not been requested as of yet, but they had an interest in the concept. As part of the evaluation WisDOT proposed to survey drivers, construction staff and law enforcement to get their feedback. Evaluations would be made on traffic operations, work-zone crashes and color retention/reflectivity of the markings. Video from freeway traffic and drive-through dashboard cameras also would be reviewed. Snow events and associated clearing operations would be tracked. The experiment was requested for 18 months to evaluate the concept through two winter seasons. FHWA approved the RTE in just over two weeks, with a minor revision that one direction be maintained as white markings to serve as a “control section.”

Orange lane markings were shown to alleviate driver confusion and, as a result, increase safety, particularly in areas that have had multiple lane shifts and markings.

Implementing orange

WisDOT did not have a specification that detailed the requirements for orange pavement markings. Contacts were made to paint manufacturers. In most cases there was little interest in producing a new color for a limited production volume. WisDOT arranged to supply the orange epoxy paint, and the contractor just provided a price for application. Since the pavement-marking subcontractor only had two epoxy trucks (for white and yellow), a truck cleaning charge also was included for each application. Installation of cold-weather lane shifts meant that the ambient temperature would be well below manufacturer’s recommendations, so the contractor and supplier were not responsible for any delamination of the markings.

WisDOT procured epoxy paint from Epoplex, which had produced orange markings for Canada and was willing to work toward a successful experiment. The cost for the epoxy was about 50% higher than white and yellow and the installation was double the cost, but the project team deemed these costs reasonable while in pursuit of a long-term solution for a safe winter work zone.

The first application of orange work-zone markings was made on Dec. 6, 2014, with air temperatures of 25°F. The epoxy adhered, and drivers maintained the lanes driving the work zone. The color of orange was not as bright as had been anticipated, however, and contact was made with Epoplex to create a more “fluorescent orange.”

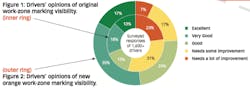

Online surveys were requested from drivers that had traversed the work zone, and WisDOT received over 1,600 responses (see Figure 1). The majority of respondents said the color needed to be improved, which reinforced the need for a more vibrant color. The acknowledgement of enhanced work zone awareness also supported continued use, regardless of the time of year.

Going fluorescent

The second application of orange markings occurred in March 2015 and utilized a fluorescent formula that increased the paint cost by 30%. The new formulation was a vast improvement, as was reflected in a follow-up survey of the same respondents who participated in the initial survey (see Figure 2). Drivers overwhelmingly supported the new fluorescent orange and preferred it to white and yellow. Awareness of the work zone increased from 54% to 81%. The Zoo IC Project Team thought these were great results and submitted a request to FHWA to continue the experiment through the remainder of the project. FHWA concurred and the orange markings were approved to be installed through August 2018.

The fluorescent orange began to fade significantly in May 2015 when the markings were exposed to more direct sunlight. Epoplex explained this was the trade-off for the fluorescent color, the formula was not resistant to ultraviolet light (UVL). Epoplex began to work on a more color-fast formula. In the meantime, the pavement-marking subcontractor no longer wanted to paint orange epoxy, due to the time and effort it took to clean out the orange from their trucks. They were willing to employ water-based orange latex paint, because the effort to switch colors was minimal. In the non-winter months, WisDOT also was interested in latex orange, so as to maintain color continuity benefits while significantly reducing the material and application costs.

Epoplex does not produce latex paint, so WisDOT reached out to Diamond Vogel, which had shown interest in the experiment. They attempted to produce a florescent orange, but determined it also would fade in UVL. They produced a color that was brighter than the initial epoxy but was noticeably darker than the fluorescent epoxy. To supplement these markings, the project team installed orange-plastic raised pavement markers (RPMs). This combination of latex and RPMs worked well until the following winter when the fluorescent epoxy was used again.

In fall of 2015, WisDOT awarded its largest contract ever—$300 million—for the core of the Zoo IC. WisDOT took all the knowledge learned under the first contract and developed items and specifications to bid on to reduce the cost. This contract included bid items for installing both orange latex and epoxy. Once again, WisDOT arranged for the procurement of the markings. Since the marking contactor had bid on placing orange markings, this contract was used to do the remainder of any orange markings on the entire project.

Upgrading the reflectivity

The fall of 2015 was particularly wet, and the project received numerous complaints that the orange lines were hard to see in wet weather. Temporary markings for work zones use regular glass beads that are less costly, due to the limited amount of time they are in place. Drivers would see permanent white/yellow epoxy paint with retroreflective beads prior to and after driving through the work zone and thought white/yellow was more visible in wet conditions than orange markings with regular beads. Therefore, they thought the white/yellow was a better color. Unfortunately, they were not comparing similar products that happened to be different colors. In order to improve the retroreflectivity of the orange markings, permanent retroreflective beads were installed on all epoxy markings beginning in December 2015. Epoplex also produced an orange that was not as vibrant, but had better resistance to UVL.

Measuring performance

WisDOT also sponsored a Smart Work Zone Deployment Initiative (SWZDI) grant to study orange markings on a separate project about 20 miles west of Milwaukee in late summer 2016. This study involved two separate crossovers to reconstruct bridges about 2 miles apart. One crossover was marked in white/yellow and the other in fluorescent orange. The markings were wet-reflective temporary tape produced by Brite-Line. In addition to stationary and drive-through dashboard video, the project utilized side-fire distance meters to determine if drivers maintained their lanes better in orange than white/yellow. Vehicle speeds also were measured. The final report on this experiment conducted by the University of Wisconsin has not been finalized at this time.

The analysis of data to determine which color provides better performance of drivers traveling 50-70 mph through work zones is very difficult. Erratic driving behavior in the work zone could be from many factors, such as changing traffic patterns, narrow lanes and shoulders, and proximity to large construction equipment. The conclusion of the Zoo IC Project Team is that the confusion of drivers in winter conditions was greatly diminished with the orange markings. Surveys documented that drivers preferred the orange markings (once the color was more fluorescent) because it minimized their confusion with old pavement marking scars, regardless of the time of year. Law enforcement overwhelmingly endorsed the new markings, which had greatly reduced complaints.

Ryan Luck, the Zoo IC chief engineer, said, “We had a safety problem during winter weather construction that we could not solve by conventional methods. The use of orange markings allowed us to make the project safer for the traveling public by providing clear direction through a complicated work zone year-round.”

That’s what Dr. McCarroll was trying to do with her groundbreaking efforts 100 years ago.